High-strength concrete typically offers compressive strengths ranging from 50 to 100 MPa, making it suitable for high-rise buildings and heavy infrastructure. Ultra-high-performance concrete surpasses this by achieving strengths above 150 MPa with superior durability and enhanced tensile properties due to fiber reinforcement. These characteristics make ultra-high-performance concrete ideal for advanced structural applications requiring exceptional load-bearing capacity and longevity.

Table of Comparison

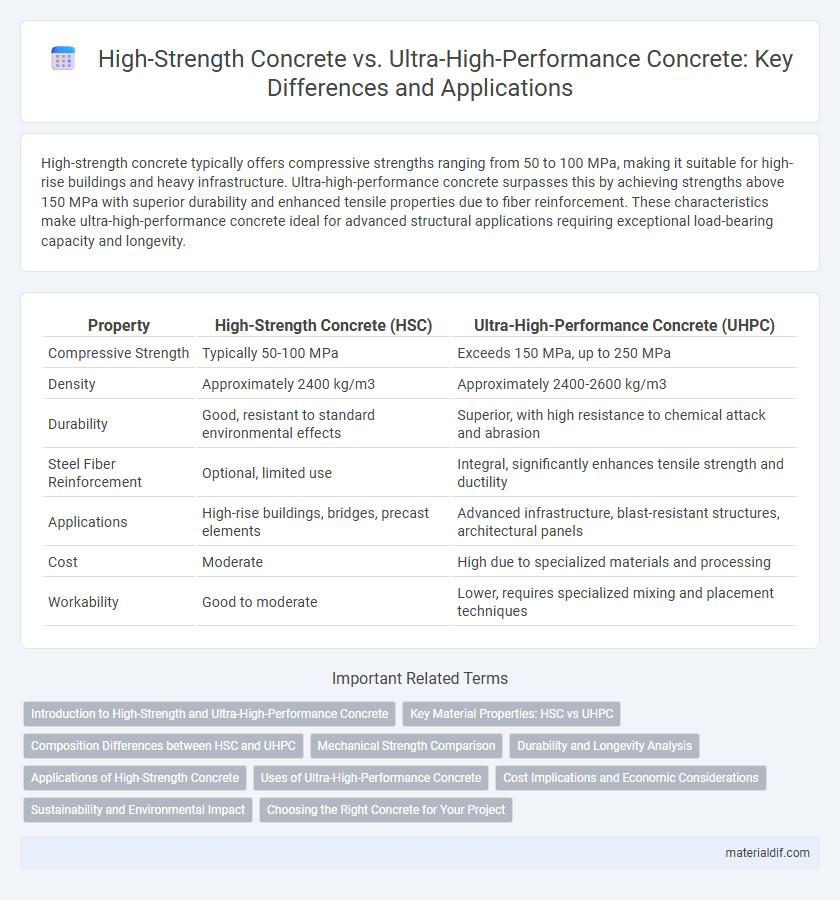

| Property | High-Strength Concrete (HSC) | Ultra-High-Performance Concrete (UHPC) |

|---|---|---|

| Compressive Strength | Typically 50-100 MPa | Exceeds 150 MPa, up to 250 MPa |

| Density | Approximately 2400 kg/m3 | Approximately 2400-2600 kg/m3 |

| Durability | Good, resistant to standard environmental effects | Superior, with high resistance to chemical attack and abrasion |

| Steel Fiber Reinforcement | Optional, limited use | Integral, significantly enhances tensile strength and ductility |

| Applications | High-rise buildings, bridges, precast elements | Advanced infrastructure, blast-resistant structures, architectural panels |

| Cost | Moderate | High due to specialized materials and processing |

| Workability | Good to moderate | Lower, requires specialized mixing and placement techniques |

Introduction to High-Strength and Ultra-High-Performance Concrete

High-strength concrete (HSC) typically achieves compressive strengths above 40 MPa, making it suitable for structures demanding enhanced durability and load-bearing capacity. Ultra-high-performance concrete (UHPC) surpasses traditional HSC with compressive strengths exceeding 150 MPa and incorporates fine powders, fibers, and optimized particle packing for superior mechanical properties. Both HSC and UHPC improve structural performance, but UHPC offers exceptional tensile strength, durability, and resistance to environmental degradation.

Key Material Properties: HSC vs UHPC

High-strength concrete (HSC) typically exhibits compressive strengths ranging from 50 to 100 MPa, offering improved durability and reduced permeability compared to conventional concrete. Ultra-high-performance concrete (UHPC) surpasses these values with compressive strengths exceeding 150 MPa, along with exceptional tensile strength and enhanced ductility due to fiber reinforcement. UHPC also demonstrates superior resistance to abrasion, chemical attacks, and freeze-thaw cycles, making it ideal for demanding structural applications.

Composition Differences between HSC and UHPC

High-strength concrete (HSC) typically contains a lower water-to-cement ratio, with conventional aggregates and supplementary cementitious materials like fly ash or silica fume enhancing strength. Ultra-high-performance concrete (UHPC) incorporates a denser matrix with fine powders such as quartz flour, high cement content, and steel fibers, combined with very low water-to-cement ratios below 0.25 to achieve exceptional mechanical properties. The distinct composition differences result in UHPC having a much finer microstructure and superior durability compared to HSC.

Mechanical Strength Comparison

High-strength concrete typically achieves compressive strengths between 50 and 100 MPa, making it suitable for demanding structural applications. Ultra-high-performance concrete (UHPC) exceeds 150 MPa in compressive strength, with some formulations surpassing 200 MPa, due to its dense microstructure and fiber reinforcement. The superior mechanical performance of UHPC results in enhanced durability, reduced cross-sectional dimensions, and improved fatigue resistance compared to traditional high-strength concrete.

Durability and Longevity Analysis

High-strength concrete (HSC) typically exhibits compressive strengths between 6,000 to 10,000 psi, providing good durability for structural applications but may suffer from microcracking and reduced permeability over time. Ultra-high-performance concrete (UHPC), with compressive strengths exceeding 20,000 psi, offers superior durability due to its dense microstructure, enhanced resistance to chemical attacks, and significantly reduced porosity. UHPC's longevity surpasses HSC, making it ideal for infrastructure exposed to harsh environmental conditions and aggressive loading cycles.

Applications of High-Strength Concrete

High-strength concrete, typically defined by a compressive strength above 6,000 psi, is extensively used in high-rise buildings, bridge supports, and infrastructure requiring enhanced load-bearing capacity and durability. Its applications include structural elements such as columns, beams, and slabs where increased strength is essential to reduce cross-sectional dimensions and optimize material use. Compared to ultra-high-performance concrete, high-strength concrete offers a balance of strength and cost-effectiveness for large-scale construction projects.

Uses of Ultra-High-Performance Concrete

Ultra-high-performance concrete (UHPC) is extensively used in bridges, high-rise buildings, and protective structures due to its exceptional tensile strength, durability, and resistance to environmental degradation. Its applications include precast architectural elements, seismic retrofitting, and infrastructure subjected to heavy loads or aggressive conditions. UHPC's superior mechanical properties and longevity make it ideal for critical infrastructure requiring enhanced performance beyond high-strength concrete capabilities.

Cost Implications and Economic Considerations

High-strength concrete (HSC) offers improved durability and load-bearing capacity at a moderate cost premium compared to conventional concrete, making it a cost-effective choice for many structural applications. Ultra-high-performance concrete (UHPC) involves significantly higher material and production costs due to its advanced composite design and superior mechanical properties, often limiting its use to specialized projects with critical performance requirements. Economic considerations for selecting HSC or UHPC include lifecycle cost savings from enhanced durability and reduced maintenance, balanced against initial investment and project budget constraints.

Sustainability and Environmental Impact

High-strength concrete (HSC) reduces material consumption by achieving greater compressive strength compared to conventional concrete, thereby lowering carbon emissions per structural unit, while ultra-high-performance concrete (UHPC) further enhances sustainability with its extreme durability and extended service life, minimizing maintenance and reconstruction needs. UHPC's dense microstructure significantly reduces permeability, limiting corrosion and thereby mitigating environmental degradation caused by material replacements. The energy-intensive manufacturing of UHPC's specialized binders requires careful consideration, but its long-term environmental benefits often offset the initial carbon footprint in large-scale infrastructure projects.

Choosing the Right Concrete for Your Project

High-strength concrete (HSC) offers compressive strengths typically between 6,000 and 15,000 psi, making it suitable for structural applications requiring durability and load-bearing capacity. Ultra-high-performance concrete (UHPC) exceeds 20,000 psi in compressive strength and provides superior durability, density, and resistance to environmental degradation, ideal for complex architectural elements and infrastructure demanding extreme performance. Selecting between HSC and UHPC depends on project-specific factors such as structural load requirements, environmental exposure, budget constraints, and desired lifespan to ensure optimal performance and cost-efficiency.

High-strength concrete vs ultra-high-performance concrete Infographic

materialdif.com

materialdif.com