Roller-compacted concrete (RCC) offers faster construction and lower costs due to its dry consistency and the use of heavy rollers for compaction, making it ideal for large-scale projects like dams and pavements. Vibrated concrete requires mechanical vibration to remove air pockets, resulting in higher density and strength, suitable for structural applications demanding superior durability and finish. Choosing between RCC and vibrated concrete depends on project requirements for speed, cost, and physical properties.

Table of Comparison

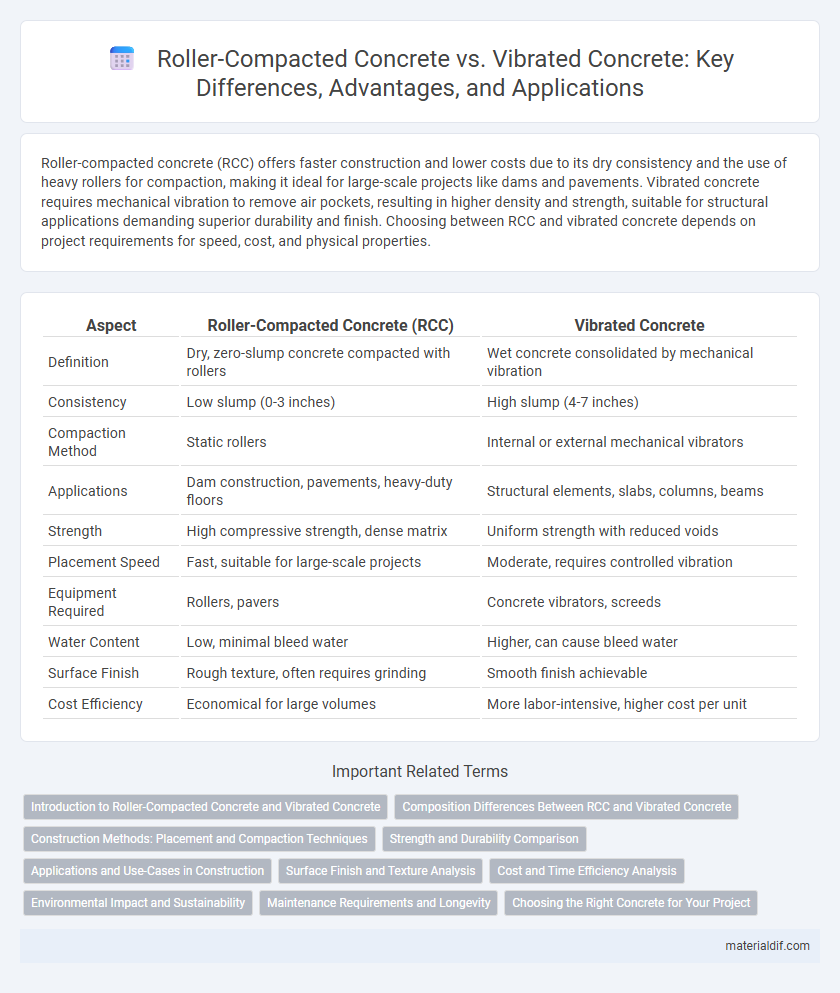

| Aspect | Roller-Compacted Concrete (RCC) | Vibrated Concrete |

|---|---|---|

| Definition | Dry, zero-slump concrete compacted with rollers | Wet concrete consolidated by mechanical vibration |

| Consistency | Low slump (0-3 inches) | High slump (4-7 inches) |

| Compaction Method | Static rollers | Internal or external mechanical vibrators |

| Applications | Dam construction, pavements, heavy-duty floors | Structural elements, slabs, columns, beams |

| Strength | High compressive strength, dense matrix | Uniform strength with reduced voids |

| Placement Speed | Fast, suitable for large-scale projects | Moderate, requires controlled vibration |

| Equipment Required | Rollers, pavers | Concrete vibrators, screeds |

| Water Content | Low, minimal bleed water | Higher, can cause bleed water |

| Surface Finish | Rough texture, often requires grinding | Smooth finish achievable |

| Cost Efficiency | Economical for large volumes | More labor-intensive, higher cost per unit |

Introduction to Roller-Compacted Concrete and Vibrated Concrete

Roller-compacted concrete (RCC) is a dry, zero-slump concrete mixture compacted with heavy rollers, commonly used for pavements, dams, and industrial floors due to its rapid placement and high durability. Vibrated concrete incorporates a wetter mix combined with mechanical vibration to remove air bubbles, enhancing strength and surface finish, making it ideal for structural elements like beams and columns. Both methods optimize concrete performance but differ in application techniques, mixture consistency, and compaction processes to suit specific engineering requirements.

Composition Differences Between RCC and Vibrated Concrete

Roller-compacted concrete (RCC) features a lower water-cement ratio and a stiffer, drier mix compared to vibrated concrete, enabling compaction through rollers rather than vibration. RCC incorporates less fine aggregate and a higher coarse aggregate content, resulting in a mix with reduced slump and increased density. In contrast, vibrated concrete contains higher water content and fines, promoting fluidity for effective consolidation via vibrating equipment.

Construction Methods: Placement and Compaction Techniques

Roller-compacted concrete (RCC) employs a dry consistency placed using heavy machinery like pavers and compacted with vibratory rollers, allowing rapid layering and minimizing formwork. Vibrated concrete relies on a wetter mix poured into formwork and compacted using internal or external vibrators to eliminate air voids and ensure density. The RCC method accelerates construction for large-scale infrastructure, while vibrated concrete suits structures requiring intricate shapes and finishes.

Strength and Durability Comparison

Roller-compacted concrete (RCC) achieves high compressive strength through low water-cement ratios and rapid compaction, making it ideal for heavy-duty pavements and dams. Vibrated concrete typically attains superior durability by eliminating air voids through mechanical vibration, enhancing resistance to freeze-thaw cycles and chemical attacks. Strength in RCC is closely linked to its dense matrix and compaction method, while vibrated concrete offers enhanced durability due to better consolidation and reduced permeability.

Applications and Use-Cases in Construction

Roller-compacted concrete (RCC) is widely used in large-scale infrastructure projects such as dams, pavements, and industrial floors due to its rapid placement, low cost, and high durability. Vibrated concrete is preferred for structural elements requiring high strength and surface finish, including beams, columns, and slabs, where vibration ensures void elimination and uniform compaction. RCC excels in applications demanding fast construction and heavy load resistance, while vibrated concrete is ideal for detailed architectural components and reinforced concrete frameworks.

Surface Finish and Texture Analysis

Roller-compacted concrete (RCC) typically exhibits a rougher surface texture due to its low slump and absence of vibration, resulting in higher friction and increased surface durability ideal for pavements. Vibrated concrete achieves a smoother, more uniform surface finish as internal vibration reduces air voids and consolidates the mix, enhancing aesthetic quality and structural integrity. Surface finish analysis shows RCC's coarse texture promotes skid resistance, while vibrated concrete's refined texture improves wear resistance and reduces permeability.

Cost and Time Efficiency Analysis

Roller-compacted concrete (RCC) offers significant cost savings due to reduced cement content and minimal formwork requirements compared to vibrated concrete, which demands more skilled labor and extensive vibration equipment. RCC's rapid placement and compaction techniques drastically cut project timelines, whereas vibrated concrete requires longer curing periods and more labor-intensive consolidation to achieve desired strength and finish. These efficiency advantages position RCC as the preferred choice for large-scale infrastructure projects where budget and schedule constraints are critical.

Environmental Impact and Sustainability

Roller-compacted concrete (RCC) significantly reduces environmental impact by minimizing cement usage and lowering water consumption compared to traditional vibrated concrete, leading to decreased carbon emissions in production. RCC's dense composition enhances durability and lifespan, reducing the frequency of repairs and reconstruction, which further conserves natural resources and energy. Vibrated concrete, while offering high strength, generally involves higher energy inputs for mixing and placement, making RCC a more sustainable choice for large-scale infrastructure projects emphasizing eco-friendly construction practices.

Maintenance Requirements and Longevity

Roller-compacted concrete (RCC) requires less frequent maintenance due to its dense and durable composition, making it highly resistant to cracking and weathering. Vibrated concrete, while offering superior surface finish and strength, demands more regular inspections and repairs to address potential surface deterioration and shrinkage cracks. RCC's longevity is enhanced by its low permeability and high abrasion resistance, ensuring extended service life in heavy-duty applications.

Choosing the Right Concrete for Your Project

Roller-compacted concrete (RCC) offers high strength and durability with faster placement, making it ideal for large-scale infrastructure projects like dams and pavements. Vibrated concrete provides superior surface finish and consolidation, suitable for structural elements requiring complex shapes and smooth aesthetics. Selecting between RCC and vibrated concrete depends on project requirements such as load-bearing capacity, surface quality, and construction speed.

Roller-compacted concrete vs vibrated concrete Infographic

materialdif.com

materialdif.com