Shotcrete application offers superior adhesion and rapid curing, making it ideal for complex shapes and vertical surfaces in concrete pet construction. Traditional pouring requires formwork and longer setting times, which can increase labor costs and limit design flexibility. Choosing shotcrete can enhance durability and streamline the building process for pet structures needing precise strength and contouring.

Table of Comparison

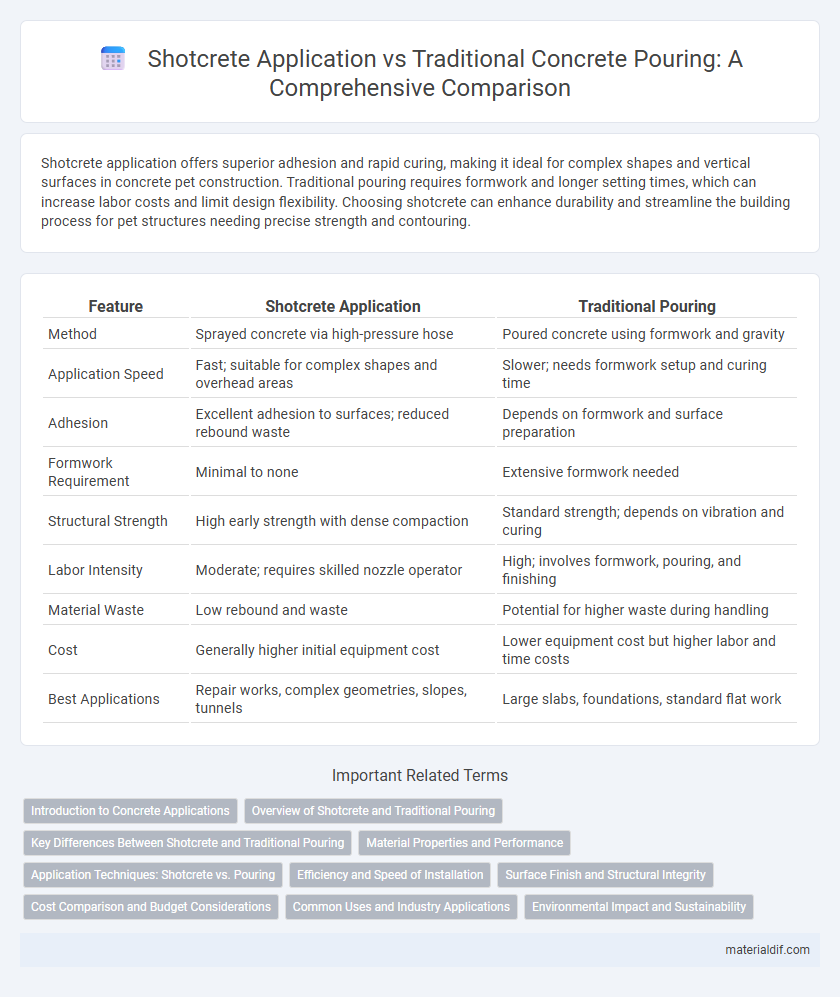

| Feature | Shotcrete Application | Traditional Pouring |

|---|---|---|

| Method | Sprayed concrete via high-pressure hose | Poured concrete using formwork and gravity |

| Application Speed | Fast; suitable for complex shapes and overhead areas | Slower; needs formwork setup and curing time |

| Adhesion | Excellent adhesion to surfaces; reduced rebound waste | Depends on formwork and surface preparation |

| Formwork Requirement | Minimal to none | Extensive formwork needed |

| Structural Strength | High early strength with dense compaction | Standard strength; depends on vibration and curing |

| Labor Intensity | Moderate; requires skilled nozzle operator | High; involves formwork, pouring, and finishing |

| Material Waste | Low rebound and waste | Potential for higher waste during handling |

| Cost | Generally higher initial equipment cost | Lower equipment cost but higher labor and time costs |

| Best Applications | Repair works, complex geometries, slopes, tunnels | Large slabs, foundations, standard flat work |

Introduction to Concrete Applications

Shotcrete application offers enhanced adaptability for complex structures by spraying concrete at high velocity, ensuring superior compaction and reduced formwork requirements. Traditional pouring relies on gravity to place concrete, which can be limited by accessibility and slower curing times. Both methods serve distinct construction needs, with shotcrete excelling in tunnels, swimming pools, and repair works, while traditional pouring remains standard for slabs and large foundations.

Overview of Shotcrete and Traditional Pouring

Shotcrete is a method of placing concrete by pneumatically projecting it at high velocity onto surfaces, enabling rapid application and superior adhesion for complex shapes and vertical structures. Traditional pouring involves casting concrete into forms, relying on gravity and requiring formwork, which can be time-consuming and less adaptable to irregular geometries. Shotcrete's high bond strength and reduced formwork needs contrast with traditional pouring's dependence on molds and slower curing times.

Key Differences Between Shotcrete and Traditional Pouring

Shotcrete involves pneumatically projecting concrete at high velocity onto surfaces, allowing for superior adhesion and minimal formwork compared to traditional pouring, which relies on gravity to place concrete into molds. Shotcrete offers enhanced compaction and flexibility for complex shapes, while traditional pouring provides uniform layers primarily suited for flat or simple geometries. The rapid setting and reduced labor costs of shotcrete contrast with the longer curing times and higher formwork expenses typical of conventional poured concrete.

Material Properties and Performance

Shotcrete exhibits superior bonding strength and durability compared to traditional pouring, due to its pneumatically applied, highly compacted material properties. The fine aggregates and controlled water-cement ratio in shotcrete enhance its resistance to cracking and improve load-bearing capacity. Traditional pouring often results in less dense concrete with potential voids, reducing structural integrity and long-term performance.

Application Techniques: Shotcrete vs. Pouring

Shotcrete application utilizes a high-velocity spraying technique that allows concrete to adhere directly onto surfaces, enabling complex shapes and vertical or overhead structures without formwork. Traditional pouring relies on gravity to fill forms, requiring extensive preparation, molds, and reinforcement to shape the concrete during curing. Shotcrete offers faster application and reduced labor costs, while traditional pouring provides better control over mix consistency and is often preferred for large, horizontal slabs.

Efficiency and Speed of Installation

Shotcrete application significantly improves efficiency and speed of installation compared to traditional concrete pouring by eliminating the need for formwork and reducing labor-intensive steps. The pneumatically projected concrete adheres instantly to surfaces, allowing for faster setting and reduced curing times. This method is especially advantageous in complex or overhead structures where traditional pouring can be cumbersome and time-consuming.

Surface Finish and Structural Integrity

Shotcrete application offers a superior surface finish with a denser, more uniform texture, reducing the need for additional smoothing compared to traditional pouring methods. The high-velocity spraying process enhances structural integrity by minimizing voids and improving material compaction, resulting in increased strength and durability. Traditional pouring may lead to segregation and honeycombing, compromising both the appearance and long-term performance of concrete structures.

Cost Comparison and Budget Considerations

Shotcrete application typically reduces labor costs and shortens project timelines compared to traditional pouring, leading to overall budget savings. Initial equipment expenses for shotcrete may be higher, but lower material waste and faster curing times offset these costs. Traditional pouring requires more formwork and extensive labor, increasing expenses and prolonging cash flow commitments in construction projects.

Common Uses and Industry Applications

Shotcrete application excels in complex structures such as tunnels, swimming pools, and slope stabilization where rapid placement and adherence to irregular surfaces are critical. Traditional pouring remains preferred for large-scale foundations, slabs, and columns due to its uniform compaction and ease of formwork use. Both methods serve key roles in construction, with shotcrete favored in mining, infrastructure repair, and architectural projects, while traditional pouring dominates residential, commercial, and industrial building foundations.

Environmental Impact and Sustainability

Shotcrete application reduces environmental impact through minimized water usage and less material waste compared to traditional pouring methods. Its faster curing time lowers energy consumption during construction and decreases carbon emissions linked to prolonged site activity. Shotcrete also allows targeted placement, improving overall material efficiency and promoting sustainable concrete practices.

Shotcrete Application vs Traditional Pouring Infographic

materialdif.com

materialdif.com