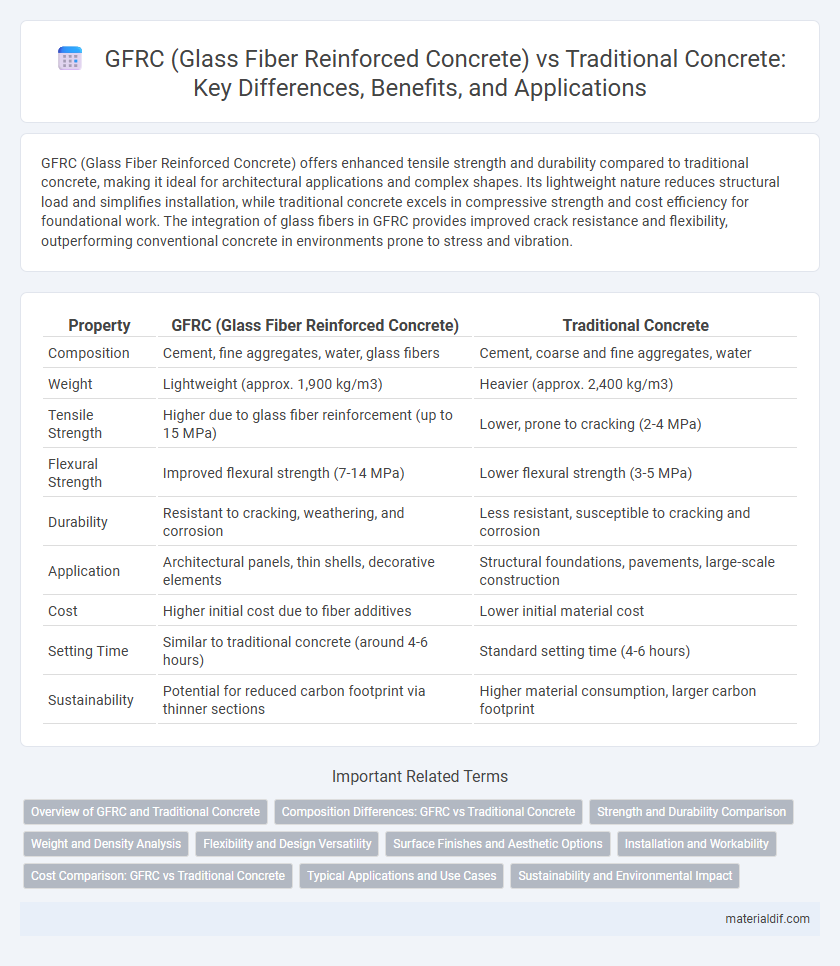

GFRC (Glass Fiber Reinforced Concrete) offers enhanced tensile strength and durability compared to traditional concrete, making it ideal for architectural applications and complex shapes. Its lightweight nature reduces structural load and simplifies installation, while traditional concrete excels in compressive strength and cost efficiency for foundational work. The integration of glass fibers in GFRC provides improved crack resistance and flexibility, outperforming conventional concrete in environments prone to stress and vibration.

Table of Comparison

| Property | GFRC (Glass Fiber Reinforced Concrete) | Traditional Concrete |

|---|---|---|

| Composition | Cement, fine aggregates, water, glass fibers | Cement, coarse and fine aggregates, water |

| Weight | Lightweight (approx. 1,900 kg/m3) | Heavier (approx. 2,400 kg/m3) |

| Tensile Strength | Higher due to glass fiber reinforcement (up to 15 MPa) | Lower, prone to cracking (2-4 MPa) |

| Flexural Strength | Improved flexural strength (7-14 MPa) | Lower flexural strength (3-5 MPa) |

| Durability | Resistant to cracking, weathering, and corrosion | Less resistant, susceptible to cracking and corrosion |

| Application | Architectural panels, thin shells, decorative elements | Structural foundations, pavements, large-scale construction |

| Cost | Higher initial cost due to fiber additives | Lower initial material cost |

| Setting Time | Similar to traditional concrete (around 4-6 hours) | Standard setting time (4-6 hours) |

| Sustainability | Potential for reduced carbon footprint via thinner sections | Higher material consumption, larger carbon footprint |

Overview of GFRC and Traditional Concrete

GFRC (Glass Fiber Reinforced Concrete) consists of a cementitious matrix reinforced with alkali-resistant glass fibers, enhancing tensile strength and reducing weight compared to traditional concrete, which primarily relies on coarse aggregates and steel reinforcement for structural integrity. GFRC offers superior durability, flexibility, and resistance to cracking, making it ideal for architectural panels, facade elements, and complex shapes, whereas traditional concrete is commonly used for foundational and structural components due to its compressive strength and cost-effectiveness. The fiber reinforcement in GFRC significantly improves impact resistance and reduces shrinkage, presenting a versatile alternative in construction applications where aesthetics and performance are critical.

Composition Differences: GFRC vs Traditional Concrete

GFRC (Glass Fiber Reinforced Concrete) incorporates alkali-resistant glass fibers into the cement matrix, enhancing tensile strength and reducing cracking compared to traditional concrete, which relies solely on aggregate and cement paste. The glass fibers in GFRC, typically comprising 5% to 8% of the mix, improve durability and flexibility without significantly increasing weight. Traditional concrete composition consists mainly of Portland cement, water, sand, and coarse aggregates, resulting in higher compressive strength but lower tensile strength and increased susceptibility to shrinkage cracks.

Strength and Durability Comparison

GFRC (Glass Fiber Reinforced Concrete) exhibits significantly higher tensile strength compared to traditional concrete due to the inclusion of glass fibers, which enhance crack resistance and structural integrity. The durability of GFRC surpasses traditional concrete as its fiber reinforcement reduces shrinkage and improves resistance to impact, weathering, and corrosion. This results in longer-lasting applications, especially in architectural and exterior cladding where strength and durability are critical.

Weight and Density Analysis

GFRC (Glass Fiber Reinforced Concrete) exhibits significantly lower density compared to traditional concrete, typically ranging from 1400 to 1800 kg/m3 versus 2200 to 2500 kg/m3 for standard mixes. This reduced weight enhances structural efficiency and facilitates easier handling and installation in construction projects. Lower density GFRC panels contribute to decreased dead loads on frameworks, allowing for innovative architectural designs without compromising strength or durability.

Flexibility and Design Versatility

GFRC (Glass Fiber Reinforced Concrete) offers superior flexibility and design versatility compared to traditional concrete, enabling the creation of intricate shapes and thin, lightweight panels without compromising strength. The embedded alkali-resistant glass fibers enhance tensile strength and reduce brittleness, allowing architects to achieve complex architectural features and decorative elements with ease. Traditional concrete's rigidity limits design potential, whereas GFRC supports innovative applications in facades, cladding, and sculptural components.

Surface Finishes and Aesthetic Options

GFRC offers superior surface finishes compared to traditional concrete due to its fine aggregate and fiberglass reinforcement, allowing for smoother textures and intricate designs. This material supports a wide range of aesthetic options, including vibrant colors, detailed molds, and varied textures that are difficult to achieve with conventional concrete. The enhanced versatility of GFRC makes it ideal for architectural applications requiring high-quality decorative surfaces.

Installation and Workability

GFRC offers superior workability compared to traditional concrete due to its lightweight composition and flexibility, enabling easier handling and faster installation on complex architectural shapes. The reduced weight of GFRC panels facilitates quicker mounting and lowers labor costs, while traditional concrete requires more curing time and heavy equipment for placement. GFRC's enhanced moldability allows for intricate designs with less formwork and minimal shrinkage, improving overall installation efficiency.

Cost Comparison: GFRC vs Traditional Concrete

GFRC (Glass Fiber Reinforced Concrete) typically incurs higher initial material costs compared to traditional concrete due to the inclusion of glass fibers and specialized admixtures. However, GFRC offers cost savings through reduced structural weight, thinner sections, and faster installation times, which can lower labor and transportation expenses. Over the lifecycle, GFRC's enhanced durability and resistance to cracking may reduce maintenance and repair costs, potentially offsetting the higher upfront investment compared to traditional concrete.

Typical Applications and Use Cases

Glass Fiber Reinforced Concrete (GFRC) is widely used in architectural cladding, decorative facades, and lightweight panels due to its high tensile strength and versatility in creating intricate shapes. Traditional concrete is preferred for structural elements like foundations, slabs, and beams where compressive strength and durability under heavy loads are critical. GFRC's resistance to cracking and reduced weight make it ideal for renovation projects and complex designs, while traditional concrete remains the standard in large-scale infrastructure and load-bearing applications.

Sustainability and Environmental Impact

GFRC (Glass Fiber Reinforced Concrete) significantly reduces carbon footprint compared to traditional concrete by requiring less cement and enabling thinner, lighter panels that lower transportation emissions. The high durability and resistance to cracking extend the lifespan of structures, minimizing the need for repairs and replacement materials over time. Recycled glass fibers in GFRC contribute to waste reduction, enhancing its sustainability profile relative to conventional concrete mixtures.

GFRC (Glass Fiber Reinforced Concrete) vs traditional concrete Infographic

materialdif.com

materialdif.com