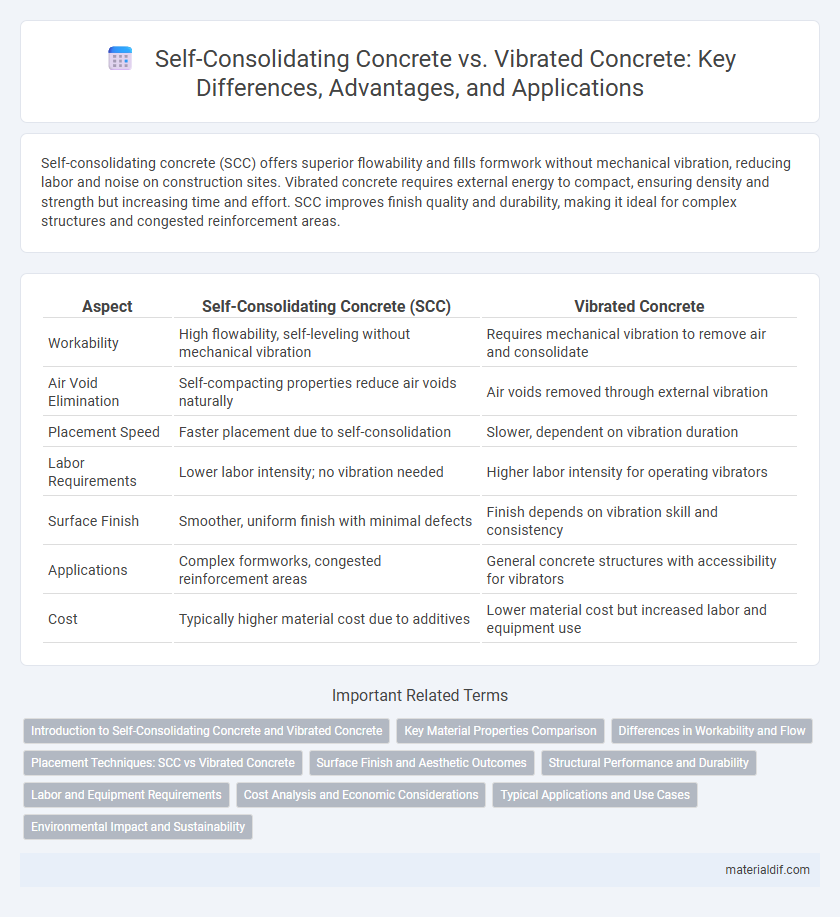

Self-consolidating concrete (SCC) offers superior flowability and fills formwork without mechanical vibration, reducing labor and noise on construction sites. Vibrated concrete requires external energy to compact, ensuring density and strength but increasing time and effort. SCC improves finish quality and durability, making it ideal for complex structures and congested reinforcement areas.

Table of Comparison

| Aspect | Self-Consolidating Concrete (SCC) | Vibrated Concrete |

|---|---|---|

| Workability | High flowability, self-leveling without mechanical vibration | Requires mechanical vibration to remove air and consolidate |

| Air Void Elimination | Self-compacting properties reduce air voids naturally | Air voids removed through external vibration |

| Placement Speed | Faster placement due to self-consolidation | Slower, dependent on vibration duration |

| Labor Requirements | Lower labor intensity; no vibration needed | Higher labor intensity for operating vibrators |

| Surface Finish | Smoother, uniform finish with minimal defects | Finish depends on vibration skill and consistency |

| Applications | Complex formworks, congested reinforcement areas | General concrete structures with accessibility for vibrators |

| Cost | Typically higher material cost due to additives | Lower material cost but increased labor and equipment use |

Introduction to Self-Consolidating Concrete and Vibrated Concrete

Self-consolidating concrete (SCC) is a high-performance concrete designed to flow and consolidate under its own weight without mechanical vibration, enhancing placement in complex formworks and congested reinforcement. Vibrated concrete relies on external vibration to remove air pockets and achieve compaction, ensuring density and strength. SCC improves construction efficiency and surface finish quality, especially in intricate structural elements, compared to traditional vibrated concrete methods.

Key Material Properties Comparison

Self-consolidating concrete (SCC) offers superior flowability and filling ability without the need for mechanical vibration, leading to enhanced consolidation in complex formworks, while vibrated concrete relies on external vibration to remove entrapped air and achieve density. SCC typically exhibits higher homogeneity and reduced segregation, resulting in improved surface finish and durability compared to vibrated concrete. Key material properties such as workability, viscosity, and stability are optimized in SCC to promote self-leveling and filling characteristics, whereas vibrated concrete emphasizes adequate slump and vibration time to ensure compaction and strength.

Differences in Workability and Flow

Self-consolidating concrete (SCC) exhibits superior workability and flow compared to vibrated concrete due to its highly fluid mix, which enables it to flow easily into complex forms without mechanical consolidation. Vibrated concrete requires external vibration to remove air pockets and ensure proper compaction, resulting in denser material but less flowability. SCC's enhanced flow characteristics reduce labor and improve finish quality, especially in intricate or congested reinforcement scenarios.

Placement Techniques: SCC vs Vibrated Concrete

Self-consolidating concrete (SCC) requires no mechanical vibration as it flows and consolidates under its own weight, filling complex forms and tight spaces seamlessly. In contrast, vibrated concrete depends on internal or external vibrators to remove air pockets and ensure proper compaction during placement. SCC placement reduces labor intensity and noise while improving surface finish quality compared to vibrated concrete.

Surface Finish and Aesthetic Outcomes

Self-consolidating concrete (SCC) delivers superior surface finish and aesthetic outcomes due to its high flowability, eliminating the need for mechanical vibration and reducing surface defects like bug holes and honeycombing. Vibrated concrete often requires extensive surface finishing to address air voids and uneven texture caused by improper compaction or excessive vibration. Choosing SCC enhances architectural detail visibility and ensures uniform color and texture, making it ideal for exposed concrete surfaces and decorative applications.

Structural Performance and Durability

Self-consolidating concrete (SCC) offers superior structural performance by achieving uniform compaction without mechanical vibration, reducing voids and segregation, which enhances load distribution and minimizes honeycombing. In contrast, vibrated concrete relies on external vibration to eliminate air pockets but may suffer from inconsistent compaction in complex forms, potentially compromising durability. SCC's improved homogeneity and dense microstructure significantly increase resistance to cracking, chloride penetration, and freeze-thaw cycles, extending the lifespan of concrete structures compared to traditional vibrated concrete.

Labor and Equipment Requirements

Self-consolidating concrete (SCC) significantly reduces labor intensity due to its high flowability, eliminating the need for mechanical vibration typically required for conventional vibrated concrete. This reduction in vibratory equipment not only lowers operational costs but also accelerates construction timelines by minimizing manpower and machinery on site. Consequently, SCC offers enhanced efficiency in projects where labor availability or equipment constraints pose challenges.

Cost Analysis and Economic Considerations

Self-consolidating concrete (SCC) often reduces labor and equipment costs due to its ability to flow and compact under its own weight, eliminating the need for mechanical vibration. Vibrated concrete requires additional labor and energy expenses to operate vibration equipment, increasing overall project costs. While SCC has a higher material cost, these savings in labor and time frequently result in a lower total cost of ownership for complex or congested formwork applications.

Typical Applications and Use Cases

Self-consolidating concrete (SCC) is ideal for complex forms, heavily reinforced structures, and architectural elements where vibration is impractical or may cause surface defects. Vibrated concrete suits standard construction projects like slabs, beams, and columns, where mechanical consolidation ensures strength and durability. SCC enhances surface finish and reduces labor costs in precast and repair work, while vibrated concrete remains the preferred choice for large-scale infrastructure and traditional cast-in-place applications.

Environmental Impact and Sustainability

Self-consolidating concrete (SCC) reduces the need for mechanical vibration, lowering energy consumption and decreasing noise pollution on construction sites, contributing to a smaller carbon footprint compared to vibrated concrete. SCC's optimized mix design often includes supplementary cementitious materials like fly ash or slag, enhancing sustainability by reducing Portland cement usage and associated CO2 emissions. Vibrated concrete typically requires more energy for compaction, making SCC a more environmentally friendly option for sustainable construction projects prioritizing resource efficiency and reduced environmental impact.

Self-Consolidating Concrete vs Vibrated Concrete Infographic

materialdif.com

materialdif.com