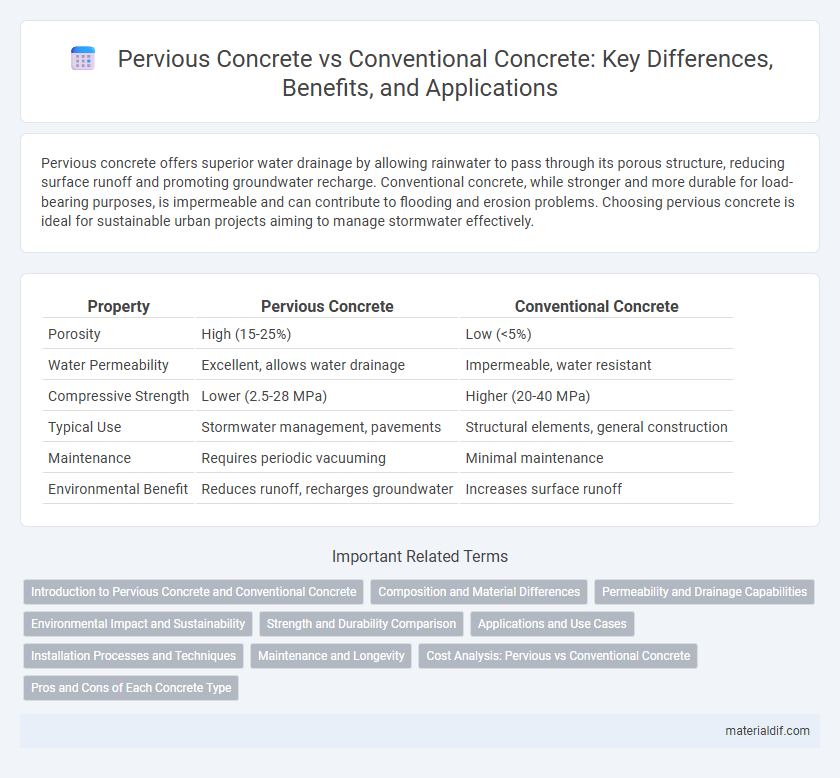

Pervious concrete offers superior water drainage by allowing rainwater to pass through its porous structure, reducing surface runoff and promoting groundwater recharge. Conventional concrete, while stronger and more durable for load-bearing purposes, is impermeable and can contribute to flooding and erosion problems. Choosing pervious concrete is ideal for sustainable urban projects aiming to manage stormwater effectively.

Table of Comparison

| Property | Pervious Concrete | Conventional Concrete |

|---|---|---|

| Porosity | High (15-25%) | Low (<5%) |

| Water Permeability | Excellent, allows water drainage | Impermeable, water resistant |

| Compressive Strength | Lower (2.5-28 MPa) | Higher (20-40 MPa) |

| Typical Use | Stormwater management, pavements | Structural elements, general construction |

| Maintenance | Requires periodic vacuuming | Minimal maintenance |

| Environmental Benefit | Reduces runoff, recharges groundwater | Increases surface runoff |

Introduction to Pervious Concrete and Conventional Concrete

Pervious concrete is a specialized concrete mix designed to allow water to permeate through its surface, reducing runoff and promoting groundwater recharge. Conventional concrete, by contrast, is a dense, impermeable material typically used for structural applications requiring high strength and durability. The porous structure of pervious concrete offers enhanced stormwater management benefits, making it ideal for pavements, parking lots, and other sustainable infrastructure projects.

Composition and Material Differences

Pervious concrete consists of a mixture of cement, coarse aggregates, and minimal fine aggregates, creating a porous structure that enhances water permeability. Conventional concrete includes a balanced ratio of cement, fine aggregates, coarse aggregates, and water, resulting in a dense, less permeable material. The key material difference lies in the reduced fine aggregate content in pervious concrete, which forms interconnected voids for effective drainage.

Permeability and Drainage Capabilities

Pervious concrete features high permeability due to its interconnected void structure, allowing water to pass through quickly and reducing runoff. In contrast, conventional concrete has a dense matrix with minimal voids, resulting in low permeability and poor drainage capabilities. This makes pervious concrete ideal for sustainable urban drainage systems and stormwater management.

Environmental Impact and Sustainability

Pervious concrete significantly reduces stormwater runoff by allowing water infiltration, which helps replenish groundwater and reduces erosion, contrasting with conventional concrete that creates impervious surfaces causing increased runoff and potential flooding. The production of pervious concrete typically uses less cement and incorporates recycled aggregates, lowering carbon emissions and resource depletion compared to traditional concrete mixes. Its sustainability benefits extend to urban heat island mitigation through increased permeability and reduced surface temperatures.

Strength and Durability Comparison

Pervious concrete typically exhibits lower compressive strength compared to conventional concrete, often ranging between 3000 to 4000 psi, while conventional concrete commonly achieves strengths above 4000 psi. The open-void structure of pervious concrete enhances water permeability but reduces overall density, impacting its long-term durability under heavy loading conditions. Conventional concrete demonstrates superior resistance to freeze-thaw cycles and abrasion, making it more durable for structural applications requiring high strength and longevity.

Applications and Use Cases

Pervious concrete is primarily used in applications requiring efficient stormwater management, such as parking lots, sidewalks, and low-traffic roads, enabling water infiltration and reducing runoff. Conventional concrete is preferred for structural applications including highways, bridges, and buildings due to its high compressive strength and durability. Pervious concrete supports sustainable urban drainage systems, while conventional concrete remains essential for load-bearing infrastructure.

Installation Processes and Techniques

Pervious concrete installation requires careful mix design and precise placement techniques to maintain its porous structure, often involving minimal compaction using a screed and light rolling to preserve void spaces. Conventional concrete installation involves thorough mixing, extensive vibration, and consolidation to achieve a dense, impermeable surface. The distinct curing and finishing methods cater to pervious concrete's need for rapid drainage while conventional concrete emphasizes durability and smoothness.

Maintenance and Longevity

Pervious concrete requires regular cleaning to prevent clogging and maintain its permeability, which is essential for effective stormwater management, while conventional concrete generally demands less frequent maintenance focused on surface repairs. The longevity of pervious concrete can be compromised by debris accumulation and freeze-thaw cycles if not properly maintained, whereas conventional concrete typically offers greater durability and resistance to environmental wear under standard conditions. Proper upkeep of pervious concrete involves vacuuming and pressure washing, extending its service life and functionality in drainage applications.

Cost Analysis: Pervious vs Conventional Concrete

Pervious concrete generally incurs higher initial costs due to specialized materials and installation requirements, averaging 10-20% more than conventional concrete. However, lower long-term expenses arise from reduced stormwater management needs and minimized drainage infrastructure. Life-cycle cost analysis often reveals that pervious concrete can be more economical in environmentally sensitive projects despite upfront investment.

Pros and Cons of Each Concrete Type

Pervious concrete offers excellent water drainage and reduces runoff, making it ideal for sustainable construction, but it has lower compressive strength and durability compared to conventional concrete. Conventional concrete provides superior strength, durability, and versatility for structural applications but contributes to increased surface runoff and potential water pollution. Choosing between pervious and conventional concrete depends on project requirements related to load-bearing capacity, environmental impact, and drainage needs.

Pervious concrete vs conventional concrete Infographic

materialdif.com

materialdif.com