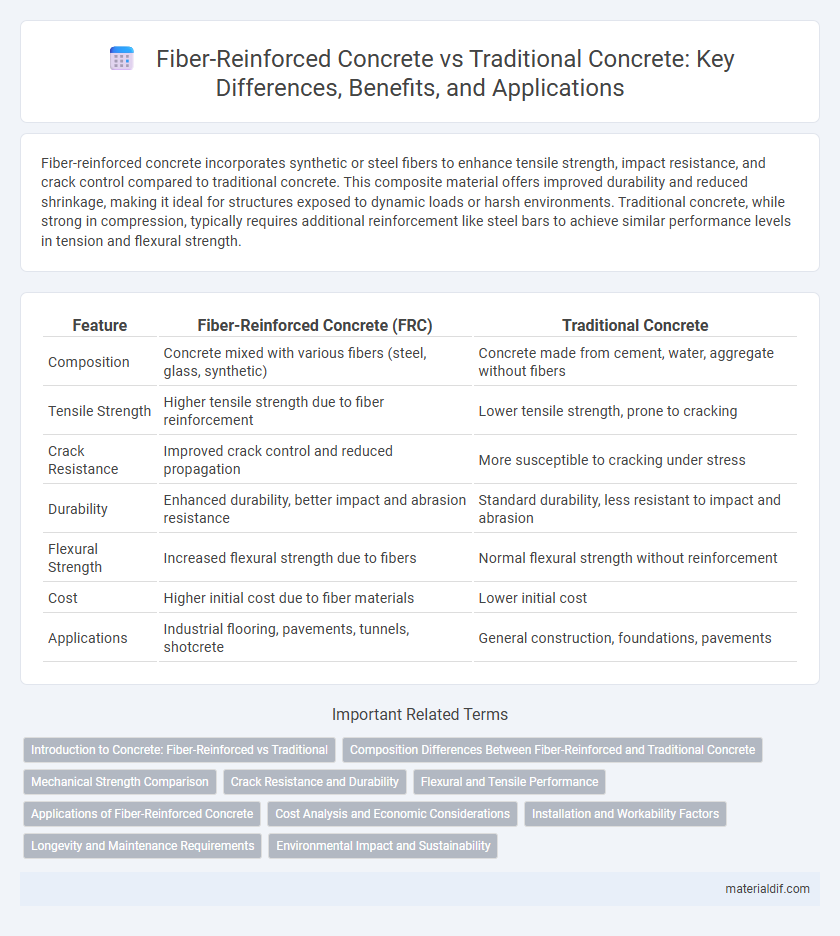

Fiber-reinforced concrete incorporates synthetic or steel fibers to enhance tensile strength, impact resistance, and crack control compared to traditional concrete. This composite material offers improved durability and reduced shrinkage, making it ideal for structures exposed to dynamic loads or harsh environments. Traditional concrete, while strong in compression, typically requires additional reinforcement like steel bars to achieve similar performance levels in tension and flexural strength.

Table of Comparison

| Feature | Fiber-Reinforced Concrete (FRC) | Traditional Concrete |

|---|---|---|

| Composition | Concrete mixed with various fibers (steel, glass, synthetic) | Concrete made from cement, water, aggregate without fibers |

| Tensile Strength | Higher tensile strength due to fiber reinforcement | Lower tensile strength, prone to cracking |

| Crack Resistance | Improved crack control and reduced propagation | More susceptible to cracking under stress |

| Durability | Enhanced durability, better impact and abrasion resistance | Standard durability, less resistant to impact and abrasion |

| Flexural Strength | Increased flexural strength due to fibers | Normal flexural strength without reinforcement |

| Cost | Higher initial cost due to fiber materials | Lower initial cost |

| Applications | Industrial flooring, pavements, tunnels, shotcrete | General construction, foundations, pavements |

Introduction to Concrete: Fiber-Reinforced vs Traditional

Fiber-reinforced concrete integrates discrete fibers such as steel, glass, or synthetic materials to enhance tensile strength, crack resistance, and durability, distinguishing it from traditional concrete, which relies solely on cement, aggregates, and water. This innovative composite improves structural performance by minimizing shrinkage and increasing impact resistance, making it ideal for demanding applications like industrial floors and bridge decks. Traditional concrete, while economical and widely used, is more susceptible to cracking and requires additional reinforcement methods to achieve similar structural resilience.

Composition Differences Between Fiber-Reinforced and Traditional Concrete

Fiber-reinforced concrete incorporates discrete fibers such as steel, glass, or synthetic materials uniformly distributed within the cementitious matrix, enhancing tensile strength and crack resistance. Traditional concrete primarily consists of cement, aggregates, and water, lacking these reinforcing fibers, which limits its ability to control cracking under stress. The inclusion of fibers modifies the microstructure by bridging cracks and improving durability without significantly altering the mix proportions of cement and aggregates.

Mechanical Strength Comparison

Fiber-reinforced concrete exhibits significantly higher tensile strength and improved crack resistance compared to traditional concrete, enhancing its durability under mechanical stress. The incorporation of fibers such as steel, glass, or synthetic materials effectively prevents crack propagation and increases flexural strength by up to 40%. Traditional concrete, while strong in compression, lacks the enhanced toughness and impact resistance provided by fiber reinforcement, making fiber-reinforced concrete more suitable for structural applications requiring superior mechanical performance.

Crack Resistance and Durability

Fiber-reinforced concrete significantly improves crack resistance compared to traditional concrete by distributing stresses more evenly through embedded fibers, which reduce crack width and delay crack propagation. This enhanced crack control leads to superior durability, as fewer and smaller cracks minimize moisture ingress and corrosion of reinforcement. Studies indicate that fiber-reinforced concrete can extend service life by up to 50% in harsh environmental conditions, making it a preferred choice for infrastructure exposed to dynamic loads and severe weather.

Flexural and Tensile Performance

Fiber-reinforced concrete significantly enhances both flexural and tensile performance compared to traditional concrete due to the inclusion of steel, glass, or synthetic fibers that bridge cracks and distribute stress. This fiber integration increases toughness, reduces crack propagation, and improves post-crack load-bearing capacity, resulting in greater ductility and durability under bending and tension forces. Traditional concrete, reliant solely on its cement matrix, exhibits lower tensile strength and tends to fail abruptly without the strain-hardening behavior seen in fiber-reinforced composites.

Applications of Fiber-Reinforced Concrete

Fiber-reinforced concrete (FRC) enhances durability and crack resistance, making it ideal for industrial floors, bridges, tunnels, and pavements exposed to heavy loading and environmental stress. Its superior impact resistance and reduced shrinkage are beneficial for precast panels, shotcrete applications, and infrastructure requiring long-term performance. FRC's ability to distribute tensile stresses uniformly extends the service life of marine structures, airport runways, and parking decks.

Cost Analysis and Economic Considerations

Fiber-reinforced concrete incurs higher initial costs due to the price of synthetic or steel fibers, which can increase material expenses by 15-30% compared to traditional concrete. However, its enhanced durability and reduced maintenance needs often result in lower lifecycle costs, making it economically advantageous for infrastructure projects with long service lives. Cost-benefit analysis typically favors fiber-reinforced concrete in large-scale applications where extended performance and minimized repair frequency translate into significant financial savings.

Installation and Workability Factors

Fiber-reinforced concrete offers enhanced workability due to the uniform distribution of fibers, which reduces segregation and improves mixing consistency compared to traditional concrete. Installation is often more efficient as fiber-reinforced mixes require less reinforcement placement and avoid the need for steel mesh or rebar, reducing labor and time. However, careful consideration of fiber content and type is essential to maintain flowability and ensure optimal placement without compromising structural integrity.

Longevity and Maintenance Requirements

Fiber-reinforced concrete exhibits enhanced longevity due to its improved resistance to cracking, shrinkage, and impact, resulting from the embedded fibers that distribute stress more evenly throughout the material. Maintenance requirements for fiber-reinforced concrete are significantly lower than traditional concrete, as the reduced crack propagation minimizes the need for frequent repairs and resurfacing. These durability advantages make fiber-reinforced concrete an optimal choice for infrastructure projects demanding long service life and reduced upkeep costs.

Environmental Impact and Sustainability

Fiber-reinforced concrete significantly reduces environmental impact by enhancing durability and extending the lifespan of structures, which decreases the need for frequent repairs and material replacements compared to traditional concrete. The incorporation of synthetic or natural fibers in fiber-reinforced concrete improves resistance to cracking and shrinkage, thereby minimizing maintenance-related emissions and resource consumption. This sustainable characteristic contributes to lower carbon footprints throughout the concrete lifecycle, promoting eco-friendly construction practices.

Fiber-Reinforced Concrete vs Traditional Concrete Infographic

materialdif.com

materialdif.com