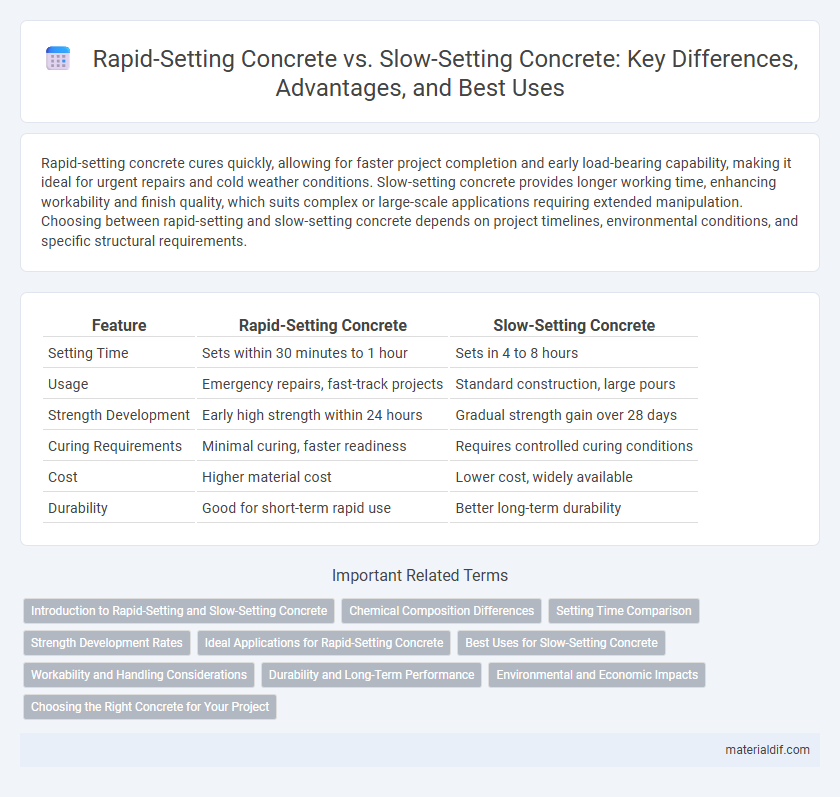

Rapid-setting concrete cures quickly, allowing for faster project completion and early load-bearing capability, making it ideal for urgent repairs and cold weather conditions. Slow-setting concrete provides longer working time, enhancing workability and finish quality, which suits complex or large-scale applications requiring extended manipulation. Choosing between rapid-setting and slow-setting concrete depends on project timelines, environmental conditions, and specific structural requirements.

Table of Comparison

| Feature | Rapid-Setting Concrete | Slow-Setting Concrete |

|---|---|---|

| Setting Time | Sets within 30 minutes to 1 hour | Sets in 4 to 8 hours |

| Usage | Emergency repairs, fast-track projects | Standard construction, large pours |

| Strength Development | Early high strength within 24 hours | Gradual strength gain over 28 days |

| Curing Requirements | Minimal curing, faster readiness | Requires controlled curing conditions |

| Cost | Higher material cost | Lower cost, widely available |

| Durability | Good for short-term rapid use | Better long-term durability |

Introduction to Rapid-Setting and Slow-Setting Concrete

Rapid-setting concrete achieves initial set within minutes to hours, making it ideal for urgent repairs and fast-paced construction projects. Slow-setting concrete cures gradually over days to weeks, providing superior strength development and durability for long-term structural applications. Selecting between rapid-setting and slow-setting concrete depends on project timelines, environmental conditions, and load requirements.

Chemical Composition Differences

Rapid-setting concrete typically contains higher amounts of calcium aluminate and calcium sulfoaluminate, which accelerate the hydration process and reduce setting time significantly. Slow-setting concrete relies more on ordinary Portland cement with lower aluminate content, resulting in a gradual hydration reaction that prolongs setting and curing periods. These chemical composition differences directly impact the concrete's strength development and suitability for time-sensitive construction projects.

Setting Time Comparison

Rapid-setting concrete typically achieves initial set within 20 to 40 minutes, making it ideal for urgent repairs and fast-track construction projects. Slow-setting concrete requires several hours, often 6 to 12 hours, to reach initial set, providing extended workability and ease in complex formworks. The choice between these types hinges on project timelines, curing requirements, and environmental factors influencing hydration rates.

Strength Development Rates

Rapid-setting concrete achieves high early strength within hours, making it ideal for urgent repairs and fast-track construction projects. Slow-setting concrete gains strength gradually over days or weeks, providing enhanced long-term durability and resistance to environmental stressors. The rate of strength development impacts project timelines, load-bearing capacity, and overall structural performance.

Ideal Applications for Rapid-Setting Concrete

Rapid-setting concrete is ideal for applications requiring quick turnaround times such as emergency repairs, road patching, and cold weather concreting where early strength gain is critical. It is commonly used in airport runways, bridge decks, and industrial flooring to minimize downtime and maintain structural integrity under fast-paced project timelines. Its accelerated curing properties make it suitable for areas with limited access or demanding environmental conditions.

Best Uses for Slow-Setting Concrete

Slow-setting concrete is ideal for large-scale construction projects requiring extended work time, such as bridges, dams, and commercial slabs, where precise placement and finishing are critical. Its gradual curing process minimizes thermal cracking and enhances long-term strength and durability, making it suitable for structures subjected to heavy loads and environmental stress. Slow-setting concrete also supports complex architectural designs by allowing more time for form adjustments and detailed surface treatments.

Workability and Handling Considerations

Rapid-setting concrete offers faster initial set times, allowing earlier finishing and reduced downtime, making it ideal for time-sensitive projects. Slow-setting concrete provides extended workability, giving more flexibility for complex placements and detailed finishing but requires longer curing periods. Proper selection depends on balancing project deadlines with required handling time and environmental conditions to ensure optimal performance.

Durability and Long-Term Performance

Rapid-setting concrete achieves high early strength within hours, reducing construction time but may exhibit slightly lower long-term durability due to faster hydration causing microstructural changes. Slow-setting concrete cures over days or weeks, allowing more complete hydration and resulting in enhanced long-term strength, reduced permeability, and superior resistance to environmental stressors like freeze-thaw cycles and chemical attacks. For projects requiring maximum durability and lifespan, slow-setting concrete is generally preferred despite longer curing times.

Environmental and Economic Impacts

Rapid-setting concrete reduces construction time, leading to lower labor costs and decreased energy consumption on-site, which benefits the environment by minimizing carbon emissions. Slow-setting concrete, while requiring longer curing periods, often uses traditional formulations that may rely on higher cement content, contributing to increased CO2 emissions and higher material expenses. Choosing rapid-setting concrete supports sustainable building practices by optimizing resource use and accelerating project completion, resulting in economic savings and a smaller environmental footprint.

Choosing the Right Concrete for Your Project

Rapid-setting concrete cures within minutes to hours, making it ideal for emergency repairs and projects requiring quick turnaround times, while slow-setting concrete offers extended workability and strength development, suitable for large-scale pours and intricate forming. Selecting the appropriate concrete depends on project timelines, structural requirements, and environmental conditions, where rapid-setting variants excel in time-sensitive applications and slow-setting types provide durability and flexibility. Understanding the setting times, compressive strength, and application context ensures optimal performance and longevity of the concrete structure.

Rapid-Setting Concrete vs Slow-Setting Concrete Infographic

materialdif.com

materialdif.com