High-performance concrete is engineered to achieve superior durability, workability, and resistance to environmental factors, making it ideal for complex construction projects. In contrast, high-strength concrete primarily emphasizes achieving greater compressive strength, often exceeding 6,000 psi, suitable for load-bearing structures. Understanding the specific application requirements helps in selecting between high-performance and high-strength concrete to ensure longevity and structural integrity.

Table of Comparison

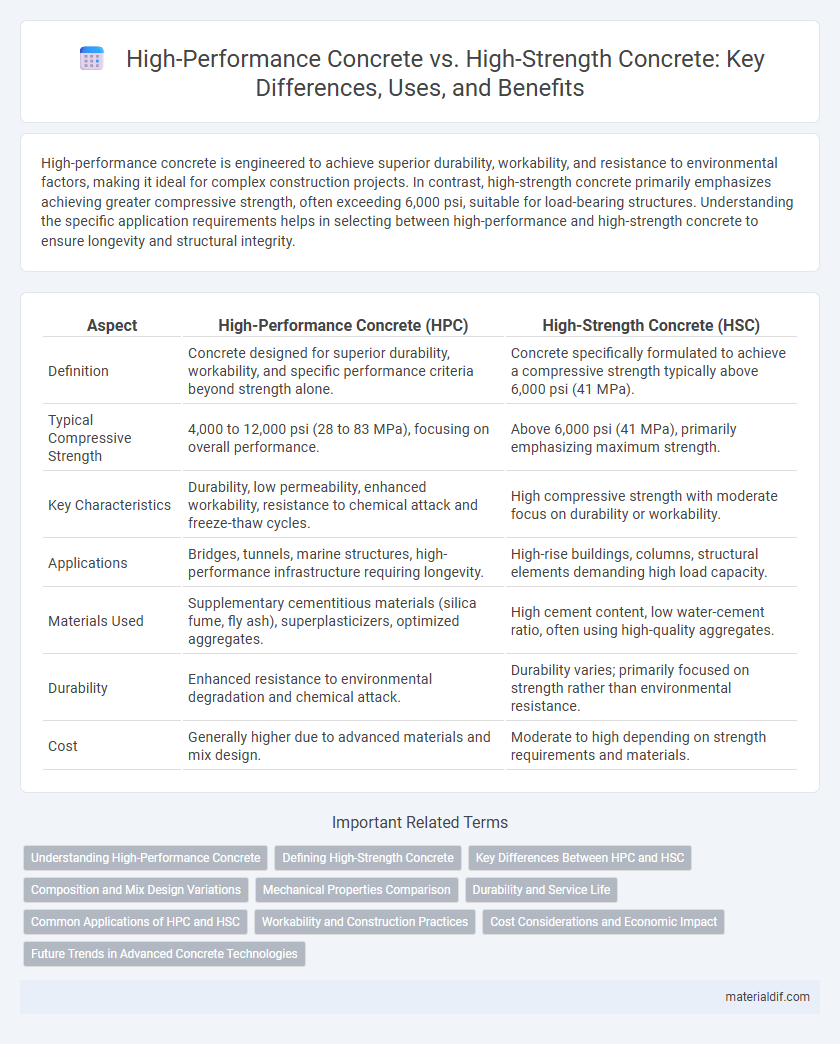

| Aspect | High-Performance Concrete (HPC) | High-Strength Concrete (HSC) |

|---|---|---|

| Definition | Concrete designed for superior durability, workability, and specific performance criteria beyond strength alone. | Concrete specifically formulated to achieve a compressive strength typically above 6,000 psi (41 MPa). |

| Typical Compressive Strength | 4,000 to 12,000 psi (28 to 83 MPa), focusing on overall performance. | Above 6,000 psi (41 MPa), primarily emphasizing maximum strength. |

| Key Characteristics | Durability, low permeability, enhanced workability, resistance to chemical attack and freeze-thaw cycles. | High compressive strength with moderate focus on durability or workability. |

| Applications | Bridges, tunnels, marine structures, high-performance infrastructure requiring longevity. | High-rise buildings, columns, structural elements demanding high load capacity. |

| Materials Used | Supplementary cementitious materials (silica fume, fly ash), superplasticizers, optimized aggregates. | High cement content, low water-cement ratio, often using high-quality aggregates. |

| Durability | Enhanced resistance to environmental degradation and chemical attack. | Durability varies; primarily focused on strength rather than environmental resistance. |

| Cost | Generally higher due to advanced materials and mix design. | Moderate to high depending on strength requirements and materials. |

Understanding High-Performance Concrete

High-performance concrete (HPC) is engineered to achieve superior durability, workability, and strength beyond conventional concrete, with optimized mix designs incorporating supplementary cementitious materials like fly ash, silica fume, or slag. HPC enhances resistance to chemical attack, freeze-thaw cycles, and abrasion, making it ideal for infrastructure exposed to harsh environments. The focus on microstructure refinement and optimized particle packing in HPC results in improved long-term performance and sustainability compared to high-strength concrete, which primarily emphasizes compressive strength.

Defining High-Strength Concrete

High-strength concrete is defined by its compressive strength, typically exceeding 6,000 psi (approximately 40 MPa), achieved through optimized mix designs with lower water-cement ratios and high-quality aggregates. It emphasizes structural capacity and durability, making it suitable for skyscrapers, bridges, and other demanding infrastructure. Unlike high-performance concrete, which targets a broader range of properties including workability and durability, high-strength concrete specifically prioritizes maximum load-bearing capability.

Key Differences Between HPC and HSC

High-Performance Concrete (HPC) emphasizes durability, workability, and long-term performance under specific environmental conditions, incorporating advanced admixtures and optimized mix designs. High-Strength Concrete (HSC) primarily focuses on achieving superior compressive strength, often exceeding 6000 psi, through a higher cement content and lower water-cement ratio. The key differences lie in HPC's balanced approach to mechanical properties and durability, while HSC targets maximum strength for structural applications.

Composition and Mix Design Variations

High-performance concrete (HPC) incorporates supplementary cementitious materials like fly ash, silica fume, and slag to enhance durability, workability, and sustainability, whereas high-strength concrete (HSC) primarily emphasizes achieving compressive strengths above 6,000 psi through increased cement content and reduced water-cement ratio. HPC mix design balances optimized particle packing and admixture use to improve long-term performance characteristics, while HSC mix designs concentrate on maximizing strength parameters by limiting water content and using superplasticizers for workability. Both rely on precise proportioning, but HPC targets a broader set of performance criteria beyond strength, including impermeability and resistance to chemical attack.

Mechanical Properties Comparison

High-Performance Concrete (HPC) exhibits enhanced durability, superior workability, and improved resistance to environmental stressors compared to High-Strength Concrete (HSC), which primarily focuses on achieving high compressive strength often above 6000 psi. Mechanically, HPC balances strength with toughness, exhibiting higher tensile strength and better modulus of elasticity, while HSC may show brittleness despite its high compressive capacity. The optimized microstructure of HPC improves flexural strength and reduces permeability, contributing to longer service life under mechanical loads.

Durability and Service Life

High-performance concrete (HPC) offers superior durability compared to high-strength concrete (HSC) due to its enhanced resistance to environmental stressors such as freeze-thaw cycles, chemical attacks, and abrasion. While high-strength concrete primarily focuses on achieving maximum compressive strength often above 6,000 psi, HPC balances strength with durability by optimizing its microstructure and reducing permeability. This balanced performance significantly extends the service life of structures by minimizing deterioration and maintenance needs over time.

Common Applications of HPC and HSC

High-Performance Concrete (HPC) is commonly used in infrastructure projects such as bridges, tunnels, and highways due to its enhanced durability, resistance to environmental stressors, and superior workability. High-Strength Concrete (HSC) finds primary application in high-rise buildings, precast concrete elements, and heavy-duty structural components where its elevated compressive strength supports greater load-bearing capacity. Both HPC and HSC are integral to modern construction, with HPC emphasizing long-term performance in harsh conditions while HSC focuses on achieving maximum strength in critical structural areas.

Workability and Construction Practices

High-performance concrete (HPC) offers superior workability compared to high-strength concrete (HSC) due to its optimized mix design, which enhances flowability and ease of placement without compromising strength. HPC incorporates supplementary cementitious materials and admixtures that improve cohesiveness, reduce segregation, and facilitate complex formwork and intricate construction details. Construction practices for HPC typically require less vibration and finishing effort, enabling faster placement and improved durability in demanding projects.

Cost Considerations and Economic Impact

High-performance concrete (HPC) often incurs higher initial costs due to the use of advanced admixtures and specialized materials, but it offers long-term economic benefits through enhanced durability, reduced maintenance, and extended service life. High-strength concrete (HSC) primarily focuses on achieving greater compressive strength, which can lead to cost savings in structural elements by reducing material volume but may not address durability as comprehensively as HPC. Evaluating the cost-effectiveness between HPC and HSC requires analyzing project-specific factors such as lifespan expectations, environmental exposure, and maintenance budgets to optimize economic impact.

Future Trends in Advanced Concrete Technologies

High-performance concrete (HPC) integrates enhanced durability, workability, and sustainability features, whereas high-strength concrete (HSC) primarily emphasizes compressive strength exceeding 6,000 psi. Emerging trends in advanced concrete technologies include the incorporation of nano-materials like graphene to improve mechanical properties and the development of self-healing composites using microcapsules containing healing agents. Future innovations focus on optimizing cement chemistry and eco-friendly admixtures to reduce carbon footprint while enhancing resilience against environmental stressors.

High-Performance Concrete vs High-Strength Concrete Infographic

materialdif.com

materialdif.com