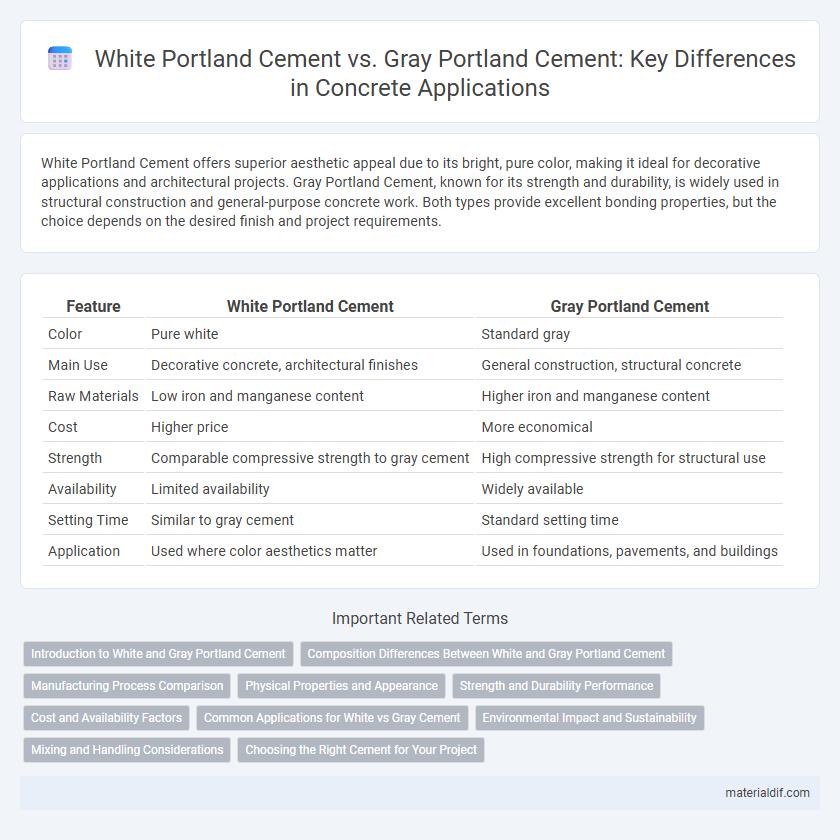

White Portland Cement offers superior aesthetic appeal due to its bright, pure color, making it ideal for decorative applications and architectural projects. Gray Portland Cement, known for its strength and durability, is widely used in structural construction and general-purpose concrete work. Both types provide excellent bonding properties, but the choice depends on the desired finish and project requirements.

Table of Comparison

| Feature | White Portland Cement | Gray Portland Cement |

|---|---|---|

| Color | Pure white | Standard gray |

| Main Use | Decorative concrete, architectural finishes | General construction, structural concrete |

| Raw Materials | Low iron and manganese content | Higher iron and manganese content |

| Cost | Higher price | More economical |

| Strength | Comparable compressive strength to gray cement | High compressive strength for structural use |

| Availability | Limited availability | Widely available |

| Setting Time | Similar to gray cement | Standard setting time |

| Application | Used where color aesthetics matter | Used in foundations, pavements, and buildings |

Introduction to White and Gray Portland Cement

White Portland Cement is prized for its high brightness and aesthetic appeal in architectural applications, produced using raw materials with low iron and manganese content to achieve its distinctive color. Gray Portland Cement, the most common type, contains higher iron and manganese levels, giving it its characteristic gray color and making it widely used in general construction for its strength and durability. Both cements share similar chemical compositions and performance characteristics but differ primarily in appearance and specific uses in decorative or structural concrete projects.

Composition Differences Between White and Gray Portland Cement

White Portland cement contains a lower amount of iron oxide, manganese oxide, and other metal oxides, which gives it its characteristic white color, while gray Portland cement has higher concentrations of these oxides resulting in its gray hue. The raw materials for white cement typically include kaolin or white clay and pure limestone, whereas gray cement uses standard limestone and clay with more impurities. Both cements share similar chemical compositions like calcium silicates, but the reduced presence of coloring oxides in white Portland cement is its defining compositional difference.

Manufacturing Process Comparison

White Portland Cement is produced using raw materials with low iron and manganese content, undergoing a higher temperature kiln firing process to achieve its distinct whiteness. In contrast, Gray Portland Cement incorporates higher amounts of iron and manganese, resulting in its characteristic gray color through a standard kiln firing operation. The controlled raw material selection and precise calcination in white cement manufacturing significantly differentiate its production from that of gray cement.

Physical Properties and Appearance

White Portland Cement exhibits a higher brightness with a pure white color due to its low iron and manganese content, making it ideal for architectural applications where aesthetics are critical. Gray Portland Cement has a typical gray color resulting from the presence of iron and other minerals, providing standard strength and durability suitable for most construction purposes. Both cements possess similar physical properties, such as compressive strength and setting time, but White Portland Cement often has a finer grind for improved workability and finish quality.

Strength and Durability Performance

White Portland Cement exhibits higher compressive strength and superior durability compared to Gray Portland Cement due to its refined raw materials and controlled manufacturing processes. The reduced iron and manganese content in White Portland Cement minimizes chemical reactions that cause discoloration and enhances resistance to sulfate and chloride attack. Consequently, White Portland Cement is preferred for architectural applications where long-term strength, visual appeal, and resistance to environmental degradation are critical.

Cost and Availability Factors

White Portland Cement generally costs 20-30% more than Gray Portland Cement due to its specialized raw materials and manufacturing process requiring low iron content. Availability of White Portland Cement is more limited, primarily produced in fewer plants worldwide, leading to longer lead times and higher shipping expenses compared to the widely accessible Gray Portland Cement. These cost and distribution differences make Gray Portland Cement the preferred choice for most large-scale concrete projects focused on budget efficiency.

Common Applications for White vs Gray Cement

White Portland Cement is commonly used in architectural projects, precast concrete products, terrazzo floors, and decorative concrete due to its aesthetic appeal and clean, bright finish. Gray Portland Cement is preferred for structural applications such as foundations, bridges, highways, and general construction where strength and durability are prioritized over color. Both types provide essential binding properties, but White Portland Cement is favored for visible surfaces, while Gray is the standard choice for load-bearing concrete.

Environmental Impact and Sustainability

White Portland Cement typically has a higher environmental impact due to the increased energy consumption during its production process, mainly because it requires raw materials with low iron content and higher kiln temperatures. Gray Portland Cement, while more common, also contributes significantly to CO2 emissions from limestone decomposition and fuel combustion but benefits from more established manufacturing efficiencies. Sustainable alternatives and improvements focus on reducing clinker content and integrating supplementary cementitious materials to lower the carbon footprint of both white and gray Portland cements.

Mixing and Handling Considerations

White Portland Cement requires careful mixing to maintain its color integrity, avoiding contamination from rust or dirt, which can cause discoloration during handling. Gray Portland Cement is more forgiving in mixing and handling, with its natural color masking minor impurities or stains. Proper storage in dry, covered conditions is essential for both types to prevent moisture absorption and ensure consistent performance in concrete applications.

Choosing the Right Cement for Your Project

White Portland cement offers superior aesthetic appeal and is ideal for architectural finishes requiring bright, clean surfaces, while gray Portland cement provides general-purpose strength for structural applications. Selecting the right cement depends on project requirements such as color, durability, and cost-effectiveness, with white cement typically used for decorative concrete and precast products and gray cement favored for foundation and infrastructure work. Understanding the specific performance characteristics and visual outcomes helps ensure optimal concrete quality and project success.

White Portland Cement vs Gray Portland Cement Infographic

materialdif.com

materialdif.com