Shotcrete is applied pneumatically, allowing it to adhere easily to complex surfaces and reducing the need for formwork, making it ideal for repairs and curved structures. Cast-in-place concrete involves pouring concrete into molds on site, providing high strength and durability for large structural elements like foundations and walls. Both methods have distinct advantages depending on project requirements, with shotcrete offering speed and flexibility, while cast-in-place ensures precise shaping and load-bearing capacity.

Table of Comparison

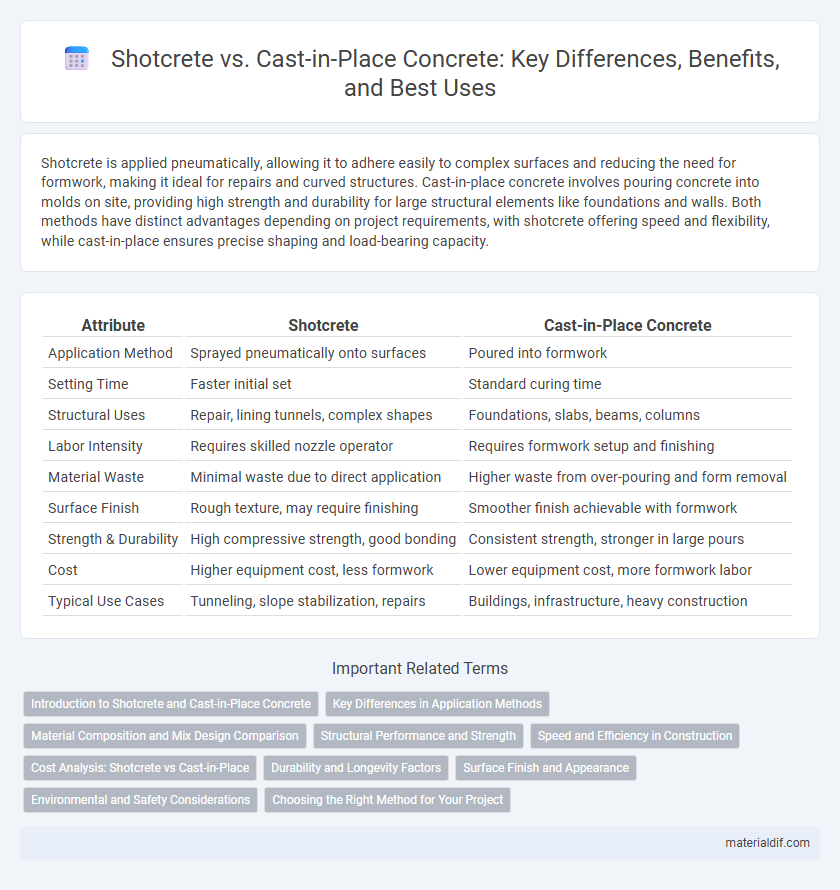

| Attribute | Shotcrete | Cast-in-Place Concrete |

|---|---|---|

| Application Method | Sprayed pneumatically onto surfaces | Poured into formwork |

| Setting Time | Faster initial set | Standard curing time |

| Structural Uses | Repair, lining tunnels, complex shapes | Foundations, slabs, beams, columns |

| Labor Intensity | Requires skilled nozzle operator | Requires formwork setup and finishing |

| Material Waste | Minimal waste due to direct application | Higher waste from over-pouring and form removal |

| Surface Finish | Rough texture, may require finishing | Smoother finish achievable with formwork |

| Strength & Durability | High compressive strength, good bonding | Consistent strength, stronger in large pours |

| Cost | Higher equipment cost, less formwork | Lower equipment cost, more formwork labor |

| Typical Use Cases | Tunneling, slope stabilization, repairs | Buildings, infrastructure, heavy construction |

Introduction to Shotcrete and Cast-in-Place Concrete

Shotcrete is a method of applying concrete by spraying a mix at high velocity onto a surface, enabling rapid placement and strong adhesion, often utilized in tunnel linings, repairs, and complex shapes. Cast-in-place concrete involves pouring concrete into formwork at the construction site, allowing for custom shapes and structural elements with high compressive strength and durability. Both methods serve different construction needs, with shotcrete offering speed and flexibility, while cast-in-place provides precise form and structural integrity.

Key Differences in Application Methods

Shotcrete involves spraying concrete pneumatically onto surfaces at high velocity, allowing for rapid application on irregular or vertical structures such as tunnels and swimming pools. Cast-in-place concrete is poured directly into formwork on-site, requiring time for setting and curing, and is commonly used for foundational slabs and structural beams. The key difference lies in shotcrete's ability to adhere without formwork, while cast-in-place relies on molds to shape the concrete before hardening.

Material Composition and Mix Design Comparison

Shotcrete utilizes a dry or wet mix with a higher cement content and often includes admixtures to enhance workability and adhesion, allowing it to be pneumatically sprayed onto surfaces. Cast-in-place concrete typically employs a wetter mix with standardized water-cement ratios and aggregate grading tailored for forming molds and structural consistency. The shotcrete mix design is optimized for immediate cohesion and reduced rebound, while cast-in-place concrete focuses on long-term strength development and uniformity within formwork.

Structural Performance and Strength

Shotcrete offers superior bonding and ability to conform to complex shapes, resulting in enhanced structural performance in irregular or overhead applications compared to cast-in-place concrete. Cast-in-place concrete generally provides higher compressive strength and durability in large-scale, uniform structures due to controlled mixing and curing processes. Choosing between the two depends on project requirements for strength, structural complexity, and application environment.

Speed and Efficiency in Construction

Shotcrete offers faster application by spraying concrete at high velocity directly onto surfaces, significantly reducing labor time compared to cast-in-place methods. This rapid placement minimizes formwork requirements and accelerates project schedules, making shotcrete ideal for complex shapes and overhead structures. Cast-in-place concrete requires extensive formwork and curing time, often leading to longer construction timelines and higher labor costs.

Cost Analysis: Shotcrete vs Cast-in-Place

Shotcrete typically reduces labor costs by eliminating formwork installation, making it more cost-effective for complex shapes and repairs. Cast-in-place concrete involves higher expenses due to formwork, longer curing times, and increased labor requirements. Material cost differences are minimal, but shotcrete's faster application significantly lowers overall project costs in many scenarios.

Durability and Longevity Factors

Shotcrete provides superior adhesion and compaction due to its high-velocity application, resulting in increased density and reduced permeability that enhance durability compared to cast-in-place concrete. Cast-in-place concrete offers controlled curing and uniform mix proportions that contribute to consistent strength development but may be more susceptible to shrinkage cracks and joint weaknesses over time. Factors such as mix design, application method, environmental exposure, and quality control critically influence the longevity of both shotcrete and cast-in-place concrete structures.

Surface Finish and Appearance

Shotcrete offers a rougher texture with the ability to conform to complex shapes, making it ideal for curved or irregular surfaces. Cast-in-place concrete provides a smoother, more uniform finish suitable for visible architectural elements and precise formwork. The choice between them depends on the desired aesthetic quality and surface smoothness requirements.

Environmental and Safety Considerations

Shotcrete significantly reduces material waste and energy consumption compared to cast-in-place concrete, enhancing its environmental sustainability. The rapid placement and reduced formwork use in shotcrete also lower emissions and decrease site disturbance, contributing to a greener construction process. From a safety perspective, shotcrete minimizes manual handling and exposure to wet concrete, reducing worker injury risks and improving overall site safety.

Choosing the Right Method for Your Project

Shotcrete offers rapid application and excellent adhesion, ideal for complex shapes and repair work, while cast-in-place concrete provides superior structural strength and customization for large-scale foundations and slabs. Project requirements such as structural load, surface finish, and accessibility determine the optimal choice between shotcrete and cast-in-place methods. Evaluating factors like curing time, labor costs, and equipment availability ensures selecting the best concrete application technique for durable, efficient results.

Shotcrete vs Cast-in-Place Concrete Infographic

materialdif.com

materialdif.com