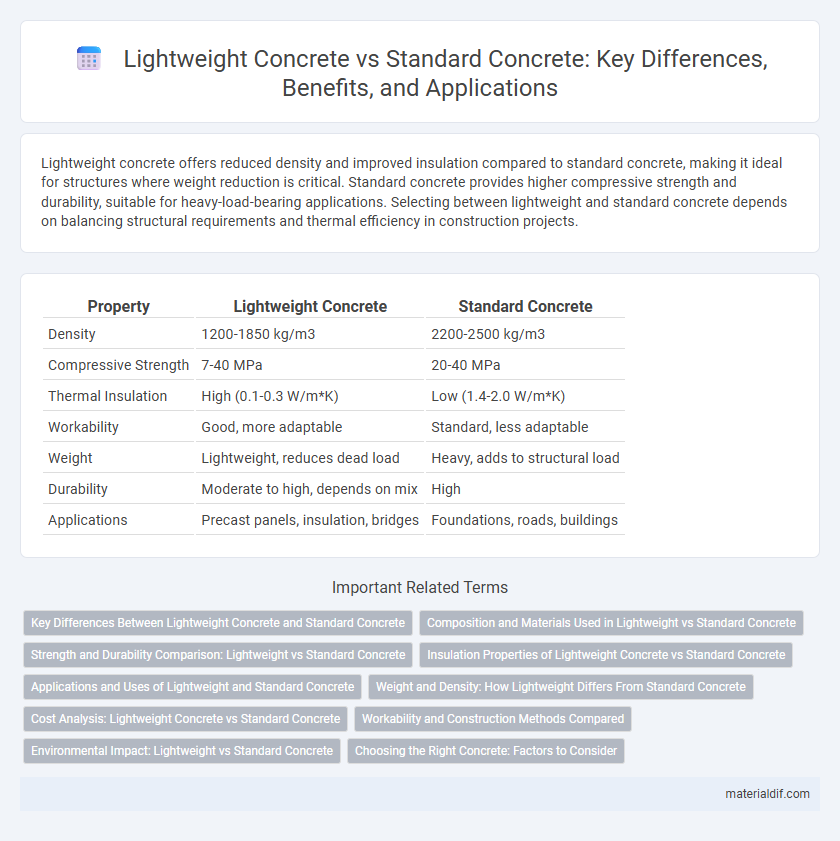

Lightweight concrete offers reduced density and improved insulation compared to standard concrete, making it ideal for structures where weight reduction is critical. Standard concrete provides higher compressive strength and durability, suitable for heavy-load-bearing applications. Selecting between lightweight and standard concrete depends on balancing structural requirements and thermal efficiency in construction projects.

Table of Comparison

| Property | Lightweight Concrete | Standard Concrete |

|---|---|---|

| Density | 1200-1850 kg/m3 | 2200-2500 kg/m3 |

| Compressive Strength | 7-40 MPa | 20-40 MPa |

| Thermal Insulation | High (0.1-0.3 W/m*K) | Low (1.4-2.0 W/m*K) |

| Workability | Good, more adaptable | Standard, less adaptable |

| Weight | Lightweight, reduces dead load | Heavy, adds to structural load |

| Durability | Moderate to high, depends on mix | High |

| Applications | Precast panels, insulation, bridges | Foundations, roads, buildings |

Key Differences Between Lightweight Concrete and Standard Concrete

Lightweight concrete contains expanded aggregates such as expanded clay or shale, resulting in a density typically between 1,440 to 1,840 kg/m3, compared to standard concrete's 2,400 kg/m3. This significant reduction in density enhances thermal insulation and reduces dead load, making lightweight concrete ideal for high-rise buildings and precast structures. Standard concrete offers higher compressive strength, generally ranging from 20 to 40 MPa, whereas lightweight concrete usually achieves lower strength values, limiting its use in load-bearing applications.

Composition and Materials Used in Lightweight vs Standard Concrete

Lightweight concrete primarily incorporates lightweight aggregates such as expanded clay, shale, or pumice, which significantly reduce the material's density while maintaining structural integrity. Standard concrete typically consists of normal weight aggregates like crushed stone or gravel combined with Portland cement, resulting in higher density and greater compressive strength. The difference in aggregate type directly influences the thermal insulation properties and weight-to-strength ratio of lightweight versus standard concrete.

Strength and Durability Comparison: Lightweight vs Standard Concrete

Lightweight concrete typically exhibits compressive strengths ranging from 17 to 35 MPa, while standard concrete commonly achieves strengths between 20 and 40 MPa, depending on mix design and curing conditions. Durability assessments show that standard concrete generally offers superior resistance to abrasion, freeze-thaw cycles, and chemical attack due to its higher density and lower porosity. Lightweight concrete, although less dense and somewhat lower in strength, provides adequate durability for structural applications and excels in reducing dead load in buildings.

Insulation Properties of Lightweight Concrete vs Standard Concrete

Lightweight concrete offers superior insulation properties compared to standard concrete due to its lower density and higher air content, which reduces heat transfer and enhances thermal resistance. The porous structure of lightweight concrete minimizes thermal conductivity, making it ideal for energy-efficient buildings and reducing heating and cooling costs. Standard concrete, with its dense composition, provides minimal insulation, resulting in higher energy consumption for temperature regulation.

Applications and Uses of Lightweight and Standard Concrete

Lightweight concrete is commonly used in applications requiring reduced structural load, such as in high-rise buildings, bridge decks, and precast panels where insulation and fire resistance are critical. Standard concrete is favored for heavy-duty construction projects including foundations, highways, and industrial floors due to its high compressive strength and durability. Both types serve distinct purposes, with lightweight concrete improving thermal efficiency and ease of handling, while standard concrete provides robust support in load-bearing structures.

Weight and Density: How Lightweight Differs From Standard Concrete

Lightweight concrete typically has a density ranging from 1,440 to 1,840 kilograms per cubic meter, significantly lower than standard concrete's density of approximately 2,400 kilograms per cubic meter. This reduction in density results from the use of lightweight aggregates such as expanded clay, pumice, or shale, which replace conventional aggregates like sand and gravel. The lower weight of lightweight concrete enhances structural efficiency by reducing dead load and improving thermal insulation without compromising compressive strength for many applications.

Cost Analysis: Lightweight Concrete vs Standard Concrete

Lightweight concrete typically costs 5-15% more than standard concrete due to the use of specialized aggregates like expanded clay or shale. However, the reduced structural load can lower overall project expenses by decreasing foundation requirements and transportation costs. In large-scale construction, these savings often offset the initial premium, making lightweight concrete a cost-effective alternative for long-term investment.

Workability and Construction Methods Compared

Lightweight concrete offers superior workability due to its lower density and better flow characteristics, facilitating easier placement and reduced labor effort compared to standard concrete. Standard concrete, with its higher density, requires more compaction and vibration during construction to eliminate air pockets and achieve desired strength. Construction methods for lightweight concrete often involve specialized mixing and curing processes to maintain structural integrity while optimizing ease of handling on-site.

Environmental Impact: Lightweight vs Standard Concrete

Lightweight concrete significantly reduces the environmental impact by lowering the amount of raw materials used, decreasing transportation emissions due to its reduced density, and improving energy efficiency in buildings through better thermal insulation properties. Standard concrete, while widely used, tends to have a higher carbon footprint because of its heavier weight, increased cement content, and greater energy consumption in production and transportation. Choosing lightweight concrete can contribute to sustainable construction practices by minimizing resource depletion and reducing greenhouse gas emissions.

Choosing the Right Concrete: Factors to Consider

Lightweight concrete offers reduced density and improved insulation, making it ideal for structures requiring lower dead loads and enhanced thermal performance. Standard concrete provides higher compressive strength and durability, suitable for heavy-load applications and structural components. Key factors to consider when choosing the right concrete include load-bearing requirements, thermal insulation needs, project budget, and specific environmental conditions.

Lightweight Concrete vs Standard Concrete Infographic

materialdif.com

materialdif.com