Polymer-modified concrete enhances durability and flexural strength compared to unmodified concrete by incorporating polymer additives that improve adhesion and reduce permeability. This modification leads to better resistance against chemical attacks, freeze-thaw cycles, and abrasion, making it ideal for harsh environments. In contrast, unmodified concrete lacks these enhanced properties, resulting in lower longevity and increased maintenance requirements.

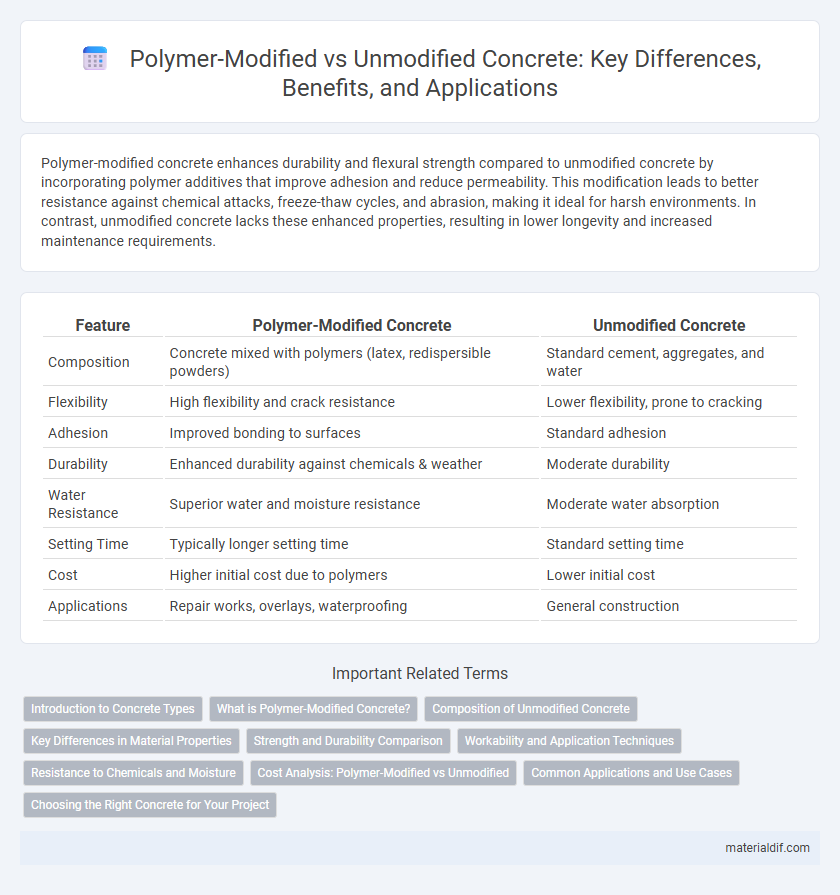

Table of Comparison

| Feature | Polymer-Modified Concrete | Unmodified Concrete |

|---|---|---|

| Composition | Concrete mixed with polymers (latex, redispersible powders) | Standard cement, aggregates, and water |

| Flexibility | High flexibility and crack resistance | Lower flexibility, prone to cracking |

| Adhesion | Improved bonding to surfaces | Standard adhesion |

| Durability | Enhanced durability against chemicals & weather | Moderate durability |

| Water Resistance | Superior water and moisture resistance | Moderate water absorption |

| Setting Time | Typically longer setting time | Standard setting time |

| Cost | Higher initial cost due to polymers | Lower initial cost |

| Applications | Repair works, overlays, waterproofing | General construction |

Introduction to Concrete Types

Polymer-modified concrete incorporates polymers such as latex, epoxy, or acrylic to enhance properties like adhesion, flexibility, and chemical resistance, making it suitable for environments requiring durability and reduced permeability. Unmodified concrete, composed primarily of cement, aggregates, and water, offers standard strength and is widely used for general construction purposes without additional enhancements. Understanding the differences in composition and performance is essential for selecting the appropriate concrete type based on structural and environmental demands.

What is Polymer-Modified Concrete?

Polymer-modified concrete (PMC) incorporates synthetic polymers such as latex, redispersible powders, or acrylics to enhance the concrete's physical and chemical properties. This modification improves bond strength, flexibility, abrasion resistance, and durability compared to unmodified concrete. PMC is widely used in applications requiring superior performance, including repair works, overlays, and waterproof structures.

Composition of Unmodified Concrete

Unmodified concrete consists primarily of Portland cement, water, and aggregates such as sand and gravel, without any chemical or polymer additives. The hydration process of the cement binder forms calcium silicate hydrate, which provides the concrete's strength and durability. This basic composition results in standard mechanical properties but lacks enhanced features like improved adhesion, flexural strength, or reduced permeability found in polymer-modified concrete.

Key Differences in Material Properties

Polymer-modified concrete exhibits enhanced tensile strength, reduced permeability, and improved resistance to chemical attack compared to unmodified concrete. The incorporation of polymers, such as styrene-butadiene rubber or acrylics, improves adhesion and flexibility, mitigating shrinkage and cracking issues commonly found in traditional concrete. These material property differences result in superior durability and longer service life for polymer-modified concrete in aggressive environments.

Strength and Durability Comparison

Polymer-modified concrete demonstrates significantly higher compressive strength and tensile strength compared to unmodified concrete due to the improved bonding of polymer molecules with cementitious materials. The incorporation of polymers enhances the concrete's resistance to cracking, abrasion, and chemical attacks, resulting in superior durability under harsh environmental conditions. Laboratory tests indicate that polymer-modified concrete exhibits reduced permeability and increased freeze-thaw resistance, extending the service life of concrete structures beyond conventional mixes.

Workability and Application Techniques

Polymer-modified concrete exhibits enhanced workability due to the addition of polymer admixtures, which improve adhesion, flexibility, and water retention compared to unmodified concrete. These polymers reduce water-cement ratio requirements while maintaining flowability, making polymer-modified concrete ideal for complex formworks and repair applications. Application techniques often involve spray or trowel methods, benefiting from the material's improved bond strength and reduced shrinkage.

Resistance to Chemicals and Moisture

Polymer-modified concrete exhibits significantly enhanced resistance to chemicals and moisture compared to unmodified concrete due to the integration of polymer additives that reduce porosity and increase adhesion. This modification minimizes water absorption and prevents chemical penetration, thus improving durability in aggressive environments like wastewater treatment plants and industrial settings. Unmodified concrete, lacking this protective polymer matrix, is more susceptible to deterioration from chemical attack and moisture ingress.

Cost Analysis: Polymer-Modified vs Unmodified

Polymer-modified concrete (PMC) typically incurs higher initial costs due to the price of polymer additives, which can range from 5% to 20% above conventional concrete expenses depending on polymer type and dosage. Despite the elevated upfront investment, PMC offers enhanced durability, reduced maintenance costs, and longer service life, often resulting in lower total lifecycle costs when compared to unmodified concrete. Cost analyses frequently highlight that higher initial expenditures in polymer-modified concrete are offset by savings from minimized repairs and improved resistance to environmental stresses.

Common Applications and Use Cases

Polymer-modified concrete is commonly used in repair works, overlays, and industrial flooring due to its enhanced durability, chemical resistance, and adhesion properties compared to unmodified concrete. Unmodified concrete remains widely applied in standard residential and commercial construction projects where cost-efficiency and basic structural performance are prioritized. Specialized infrastructure such as bridges and tunnels often benefit from polymer-modified concrete's improved tensile strength and reduced permeability.

Choosing the Right Concrete for Your Project

Polymer-modified concrete enhances durability, adhesion, and resistance to chemicals compared to unmodified concrete, making it ideal for projects exposed to harsh environments. Unmodified concrete remains cost-effective and sufficient for standard construction tasks where extreme performance is not required. Selecting the right concrete depends on project-specific factors such as environmental conditions, load requirements, and budget constraints.

Polymer-Modified Concrete vs Unmodified Concrete Infographic

materialdif.com

materialdif.com