Ultra-high-performance concrete (UHPC) offers superior compressive strength, durability, and resistance to environmental factors compared to normal-strength concrete, making it ideal for demanding structural applications. Its dense microstructure reduces permeability, enhancing longevity and reducing maintenance costs, while normal-strength concrete remains more cost-effective and suitable for standard construction projects. Choosing between UHPC and normal-strength concrete depends on the specific performance requirements and budget constraints of the project.

Table of Comparison

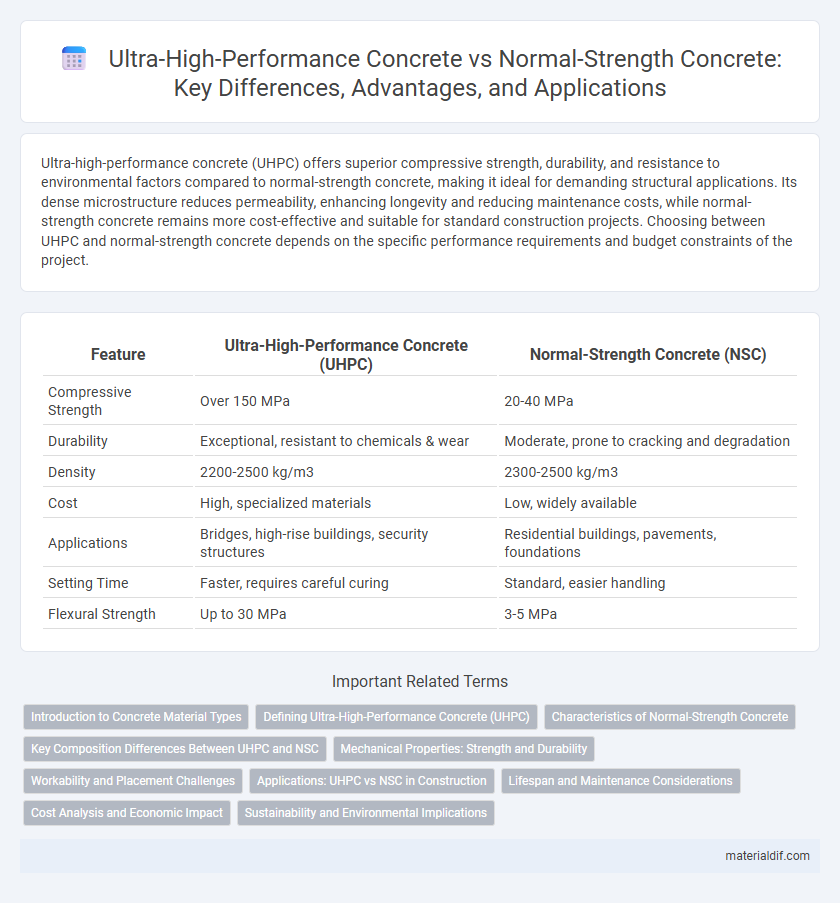

| Feature | Ultra-High-Performance Concrete (UHPC) | Normal-Strength Concrete (NSC) |

|---|---|---|

| Compressive Strength | Over 150 MPa | 20-40 MPa |

| Durability | Exceptional, resistant to chemicals & wear | Moderate, prone to cracking and degradation |

| Density | 2200-2500 kg/m3 | 2300-2500 kg/m3 |

| Cost | High, specialized materials | Low, widely available |

| Applications | Bridges, high-rise buildings, security structures | Residential buildings, pavements, foundations |

| Setting Time | Faster, requires careful curing | Standard, easier handling |

| Flexural Strength | Up to 30 MPa | 3-5 MPa |

Introduction to Concrete Material Types

Ultra-high-performance concrete (UHPC) exhibits compressive strengths exceeding 150 MPa, significantly outperforming normal-strength concrete, which typically ranges from 20 to 40 MPa. UHPC incorporates fine powders, fibers, and low water-to-cement ratios, resulting in enhanced durability, tensile strength, and resistance to environmental degradation. Normal-strength concrete, composed of cement, aggregates, and water in conventional proportions, remains widely used for general construction due to its cost-effectiveness and ease of application.

Defining Ultra-High-Performance Concrete (UHPC)

Ultra-High-Performance Concrete (UHPC) is a specialized, cementitious composite material characterized by compressive strengths exceeding 150 MPa (21,750 psi) and enhanced durability compared to normal-strength concrete. UHPC incorporates fine powders, high cement content, and fiber reinforcement, resulting in superior mechanical properties and resistance to environmental degradation. This advanced concrete type exhibits superior tensile strength, ductility, and reduced permeability, making it ideal for infrastructure requiring long-term performance and minimal maintenance.

Characteristics of Normal-Strength Concrete

Normal-strength concrete typically has a compressive strength ranging from 20 to 40 MPa, making it suitable for general construction purposes such as residential buildings and sidewalks. It consists of a standard mix of cement, water, fine aggregates, and coarse aggregates, providing adequate durability and workability for everyday applications. Unlike ultra-high-performance concrete, it has lower density, reduced tensile strength, and limited resistance to chemical attack or extreme environmental conditions.

Key Composition Differences Between UHPC and NSC

Ultra-High-Performance Concrete (UHPC) contains a significantly higher cement content, fine silica sand, and steel fibers, which contribute to its exceptional strength and durability compared to Normal-Strength Concrete (NSC). UHPC's low water-to-cement ratio and use of supplementary cementitious materials like silica fume enhance its density and reduce porosity, unlike NSC which has a higher water-to-cement ratio and coarser aggregates. These composition differences result in UHPC exhibiting superior mechanical properties, including compressive strengths often exceeding 150 MPa versus the typical 20-40 MPa range for NSC.

Mechanical Properties: Strength and Durability

Ultra-High-Performance Concrete (UHPC) exhibits compressive strengths exceeding 150 MPa, significantly outperforming Normal-Strength Concrete (NSC), which typically ranges between 20 and 40 MPa. UHPC's dense microstructure and advanced fiber reinforcement contribute to superior tensile strength, flexural strength, and enhanced durability against environmental degradation, including resistance to chloride penetration and freeze-thaw cycles. The mechanical superiority of UHPC enables extended service life and reduced maintenance compared to NSC in demanding infrastructure applications.

Workability and Placement Challenges

Ultra-High-Performance Concrete (UHPC) exhibits significantly lower workability compared to Normal-Strength Concrete (NSC), requiring precise mix design and advanced admixtures to maintain flowability without segregation. The dense matrix and high cement content in UHPC complicate placement, demanding specialized equipment and skilled labor to ensure proper consolidation and avoid defects. In contrast, NSC offers more forgiving placement characteristics with simpler vibration and finishing processes, reducing labor intensity and potential errors on site.

Applications: UHPC vs NSC in Construction

Ultra-High-Performance Concrete (UHPC) is utilized in critical infrastructure projects requiring exceptional durability and load-bearing capacity, such as bridge decks, high-rise buildings, and protective barriers. Normal-Strength Concrete (NSC) is commonly applied in residential foundations, pavements, and non-structural elements where moderate strength and cost-efficiency are prioritized. The superior mechanical properties and enhanced durability of UHPC enable longer service life and reduced maintenance compared to NSC in demanding construction environments.

Lifespan and Maintenance Considerations

Ultra-High-Performance Concrete (UHPC) offers a significantly longer lifespan than normal-strength concrete due to its superior compressive strength, often exceeding 150 MPa compared to normal concrete's 20-40 MPa, which reduces crack formation and deterioration. UHPC requires minimal maintenance over time as its dense microstructure resists chloride penetration and freeze-thaw cycles, unlike normal-strength concrete that demands frequent repairs and surface treatments to prevent corrosion and structural degradation. This durability advantage makes UHPC ideal for infrastructure projects aiming for extended service life and reduced lifecycle costs.

Cost Analysis and Economic Impact

Ultra-High-Performance Concrete (UHPC) exhibits significantly higher initial costs compared to Normal-Strength Concrete due to advanced materials and production techniques, impacting project budgets and financing. Despite the premium price, UHPC offers enhanced durability, reduced maintenance, and longer lifespan, contributing to lower life-cycle costs and improved return on investment for infrastructure projects. Economic impact assessments indicate that UHPC's superior performance can lead to decreased repair frequency and extended service intervals, ultimately generating cost savings for municipalities and private developers over time.

Sustainability and Environmental Implications

Ultra-High-Performance Concrete (UHPC) significantly reduces environmental impact by enhancing durability and extending the lifespan of structures, thereby lowering lifecycle carbon emissions compared to Normal-Strength Concrete (NSC). UHPC's dense microstructure allows for reduced material usage and improved resistance to corrosion and wear, minimizing the need for frequent repairs and replacements. Compared to NSC, UHPC contributes to sustainable construction practices by optimizing resource efficiency and reducing greenhouse gas emissions during production and maintenance phases.

Ultra-High-Performance Concrete vs Normal-Strength Concrete Infographic

materialdif.com

materialdif.com