Ordinary concrete consists of cement, water, and aggregates, offering strong compressive strength but limited tensile strength and crack resistance. Fiber-reinforced concrete incorporates fibers such as steel, glass, or synthetic materials to enhance durability, improve tensile strength, and reduce cracking. This reinforcement significantly increases structural performance and extends the lifespan of concrete applications.

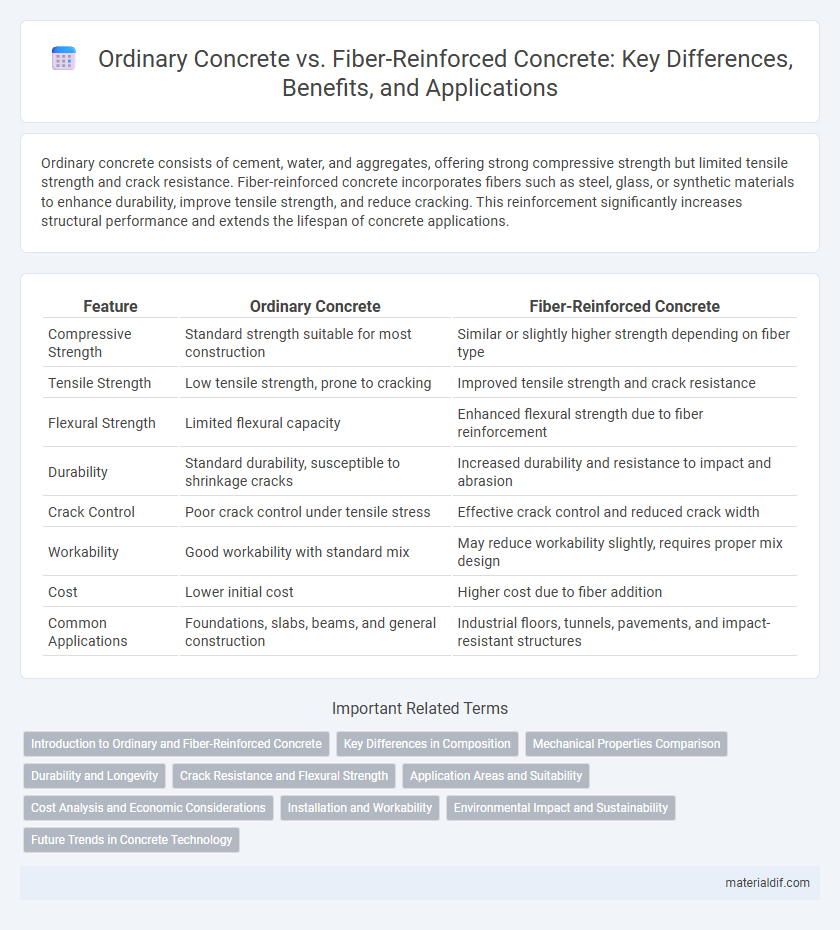

Table of Comparison

| Feature | Ordinary Concrete | Fiber-Reinforced Concrete |

|---|---|---|

| Compressive Strength | Standard strength suitable for most construction | Similar or slightly higher strength depending on fiber type |

| Tensile Strength | Low tensile strength, prone to cracking | Improved tensile strength and crack resistance |

| Flexural Strength | Limited flexural capacity | Enhanced flexural strength due to fiber reinforcement |

| Durability | Standard durability, susceptible to shrinkage cracks | Increased durability and resistance to impact and abrasion |

| Crack Control | Poor crack control under tensile stress | Effective crack control and reduced crack width |

| Workability | Good workability with standard mix | May reduce workability slightly, requires proper mix design |

| Cost | Lower initial cost | Higher cost due to fiber addition |

| Common Applications | Foundations, slabs, beams, and general construction | Industrial floors, tunnels, pavements, and impact-resistant structures |

Introduction to Ordinary and Fiber-Reinforced Concrete

Ordinary concrete consists of cement, water, and aggregates, providing compressive strength but limited tensile capacity. Fiber-reinforced concrete incorporates discrete fibers like steel, glass, or synthetic materials to enhance toughness, crack resistance, and durability. These fibers improve load distribution and control micro-cracking, resulting in superior performance compared to conventional concrete.

Key Differences in Composition

Ordinary concrete consists primarily of cement, water, and aggregates such as sand and gravel, forming a rigid but brittle material. Fiber-reinforced concrete incorporates discrete fibers made of steel, glass, synthetic, or natural materials, which are uniformly dispersed throughout the mix to improve tensile strength and crack resistance. These fibers alter the microstructure and enhance durability by arresting crack propagation and increasing the concrete's toughness.

Mechanical Properties Comparison

Fiber-reinforced concrete exhibits significantly enhanced mechanical properties compared to ordinary concrete, including higher tensile strength, improved toughness, and increased resistance to cracking and impact. The inclusion of fibers such as steel, polypropylene, or glass effectively bridges micro-cracks, leading to better load distribution and greater ductility under stress. Studies reveal that fiber-reinforced concrete can achieve up to 30-50% greater flexural strength and superior durability in harsh environments relative to conventional concrete mixes.

Durability and Longevity

Ordinary concrete typically exhibits moderate durability with susceptibility to cracking and reduced lifespan under harsh environmental conditions. Fiber-reinforced concrete incorporates synthetic or steel fibers that enhance tensile strength, reduce crack propagation, and improve resistance to freeze-thaw cycles, significantly extending service life. The enhanced microstructure of fiber-reinforced concrete contributes to superior durability and prolonged structural performance compared to traditional ordinary concrete.

Crack Resistance and Flexural Strength

Fiber-reinforced concrete exhibits significantly improved crack resistance compared to ordinary concrete due to the distribution of microfibers that bridge cracks and prevent their propagation. Its flexural strength is notably higher, often increasing by 30-50%, which enhances durability and structural integrity under bending stresses. In contrast, ordinary concrete lacks these reinforcements, making it more susceptible to brittle failure and crack formation.

Application Areas and Suitability

Ordinary concrete is widely applied in general construction projects such as residential buildings, pavements, and foundations due to its cost-effectiveness and ease of use. Fiber-reinforced concrete enhances structural performance, making it suitable for applications requiring increased durability and crack resistance, including industrial floors, bridge decks, and tunnel linings. The addition of fibers improves impact resistance and flexural strength, extending the lifespan of structures subjected to heavy loads and dynamic stresses.

Cost Analysis and Economic Considerations

Ordinary concrete generally incurs lower initial material and production costs compared to fiber-reinforced concrete, which requires the integration of synthetic or steel fibers increasing upfront expenses. However, fiber-reinforced concrete offers long-term economic benefits by enhancing durability, reducing cracking, and minimizing maintenance and repair costs over the lifecycle of infrastructure projects. Cost analyses often favor fiber-reinforced concrete in applications demanding extended service life and resistance to mechanical stresses, yielding improved return on investment despite higher initial expenditure.

Installation and Workability

Ordinary concrete offers straightforward installation with high workability, making it ideal for standard construction projects requiring easy placement and finishing. Fiber-reinforced concrete presents enhanced toughness and crack resistance but may reduce workability due to fiber inclusion, necessitating adjustments in mixing and placement techniques. Contractors must balance fiber content to maintain adequate slump and flow while achieving improved mechanical performance during installation.

Environmental Impact and Sustainability

Ordinary concrete, composed mainly of cement, aggregates, and water, typically has a high carbon footprint due to cement production's significant CO2 emissions. Fiber-reinforced concrete incorporates materials such as steel, glass, or synthetic fibers, enhancing durability and reducing the frequency of repairs and replacements, thereby lowering long-term environmental impact. The increased lifespan and improved structural integrity of fiber-reinforced concrete contribute to resource conservation and sustainability in construction projects.

Future Trends in Concrete Technology

Fiber-reinforced concrete (FRC) is increasingly favored over ordinary concrete due to its enhanced durability, crack resistance, and tensile strength, making it ideal for advanced structural applications. Future trends emphasize nanoscale fiber integration and sustainable materials to improve mechanical properties and reduce environmental impact. Innovations like self-healing fibers and smart sensors embedded in FRC promise real-time monitoring and extended lifespan of infrastructure.

Ordinary concrete vs fiber-reinforced concrete Infographic

materialdif.com

materialdif.com