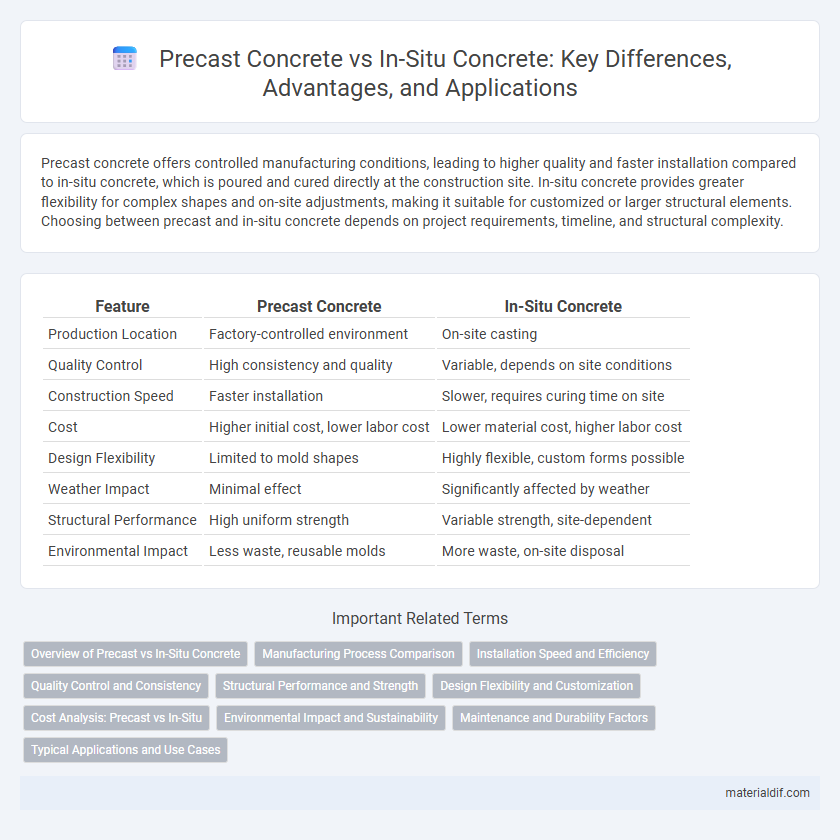

Precast concrete offers controlled manufacturing conditions, leading to higher quality and faster installation compared to in-situ concrete, which is poured and cured directly at the construction site. In-situ concrete provides greater flexibility for complex shapes and on-site adjustments, making it suitable for customized or larger structural elements. Choosing between precast and in-situ concrete depends on project requirements, timeline, and structural complexity.

Table of Comparison

| Feature | Precast Concrete | In-Situ Concrete |

|---|---|---|

| Production Location | Factory-controlled environment | On-site casting |

| Quality Control | High consistency and quality | Variable, depends on site conditions |

| Construction Speed | Faster installation | Slower, requires curing time on site |

| Cost | Higher initial cost, lower labor cost | Lower material cost, higher labor cost |

| Design Flexibility | Limited to mold shapes | Highly flexible, custom forms possible |

| Weather Impact | Minimal effect | Significantly affected by weather |

| Structural Performance | High uniform strength | Variable strength, site-dependent |

| Environmental Impact | Less waste, reusable molds | More waste, on-site disposal |

Overview of Precast vs In-Situ Concrete

Precast concrete is manufactured in controlled factory environments, ensuring consistent quality and rapid installation on-site, while in-situ concrete is poured and cured directly at the construction location, allowing for flexible designs and seamless integration with existing structures. Precast elements include beams, slabs, and panels that are transported to the site, reducing construction time and minimizing weather-related delays, whereas in-situ concrete offers adaptability for complex and customized shapes, often used in foundation and infrastructure projects. Choosing between precast and in-situ concrete depends on project requirements such as design complexity, timeline, site accessibility, and budget constraints.

Manufacturing Process Comparison

Precast concrete involves manufacturing structural components in a controlled factory environment, ensuring consistent quality through standardized casting, curing, and reinforcement procedures. In-situ concrete is mixed and poured directly at the construction site, allowing for flexibility in shape and design but often facing variability in curing conditions and quality control. The factory-controlled process of precast concrete reduces construction time and labor costs compared to the on-site casting process of in-situ concrete.

Installation Speed and Efficiency

Precast concrete offers significantly faster installation speed compared to in-situ concrete due to factory-controlled manufacturing and on-site assembly, minimizing curing time and weather-related delays. Its efficiency is enhanced by precise molding and quality control processes that reduce waste and labor costs. In contrast, in-situ concrete requires extended curing periods and on-site formwork, leading to longer project timelines and increased dependency on weather conditions.

Quality Control and Consistency

Precast concrete offers superior quality control and consistency due to factory-controlled environments where materials, mixing, and curing processes are strictly monitored. In-situ concrete quality depends heavily on site conditions, worker skill, and environmental factors, leading to variability in strength and finish. Consequently, precast concrete ensures uniform properties and reduces the risk of defects compared to the often variable quality of in-situ concrete.

Structural Performance and Strength

Precast concrete offers superior structural performance due to controlled factory conditions, ensuring higher strength and uniformity compared to in-situ concrete, which is subject to on-site environmental variations. The high compressive strength of precast elements enhances load-bearing capacity and durability, making them ideal for repetitive and high-stress applications. In contrast, in-situ concrete provides greater flexibility in design complexity but may exhibit variable strength influenced by curing conditions and workmanship.

Design Flexibility and Customization

Precast concrete offers high design flexibility through its factory-controlled manufacturing, allowing intricate shapes and consistent quality ideal for repetitive architectural elements. In-situ concrete enables extensive customization on-site, adapting to complex forms and unique project requirements with variable reinforcement and finish options. Both methods support innovative structural and aesthetic solutions, but precast excels in precision and mass production, while in-situ favors bespoke, one-off designs.

Cost Analysis: Precast vs In-Situ

Precast concrete typically offers lower labor costs due to off-site fabrication and faster on-site assembly, reducing overall project timelines. In-situ concrete involves higher expenses for formwork, labor, and site preparation, often leading to increased direct and indirect costs. However, transportation and handling of precast elements can add to expenses, making cost-effectiveness dependent on project scale and location.

Environmental Impact and Sustainability

Precast concrete reduces environmental impact through controlled factory production, minimizing waste and improving material efficiency compared to in-situ concrete, which often generates more on-site waste and emissions. The use of precast elements enables better quality control and durability, leading to longer lifespans and lower resource consumption over time. In-situ concrete's reliance on extensive formwork and curing processes can increase water use and carbon emissions, making precast concrete a more sustainable choice for eco-friendly construction.

Maintenance and Durability Factors

Precast concrete exhibits superior durability due to factory-controlled curing conditions, resulting in enhanced resistance to cracks, corrosion, and weathering compared to in-situ concrete. Maintenance needs for precast structures are typically lower as the uniform quality reduces the likelihood of defects and surface deterioration. In-situ concrete, exposed to variable site conditions and inconsistent curing, often requires more frequent repairs and maintenance to address shrinkage cracks and structural weaknesses.

Typical Applications and Use Cases

Precast concrete is commonly used in large-scale commercial buildings, bridges, and modular construction due to its controlled factory production ensuring high quality and faster installation. In-situ concrete is preferred for foundations, complex structural components, and custom shapes where on-site casting allows for flexibility and adaptation to specific project requirements. Both methods serve critical roles in construction, with precast offering efficiency and uniformity while in-situ provides versatility and structural continuity.

Precast Concrete vs In-Situ Concrete Infographic

materialdif.com

materialdif.com