Water-reducing admixtures and superplasticizers improve concrete workability by reducing water content, but their effectiveness varies significantly. Water-reducing admixtures typically lower water demand by 5-10%, enhancing strength and durability, while superplasticizers can reduce water content by up to 30%, enabling highly flowable or self-consolidating concrete. Selecting the appropriate admixture depends on project requirements for workability, strength, and curing time.

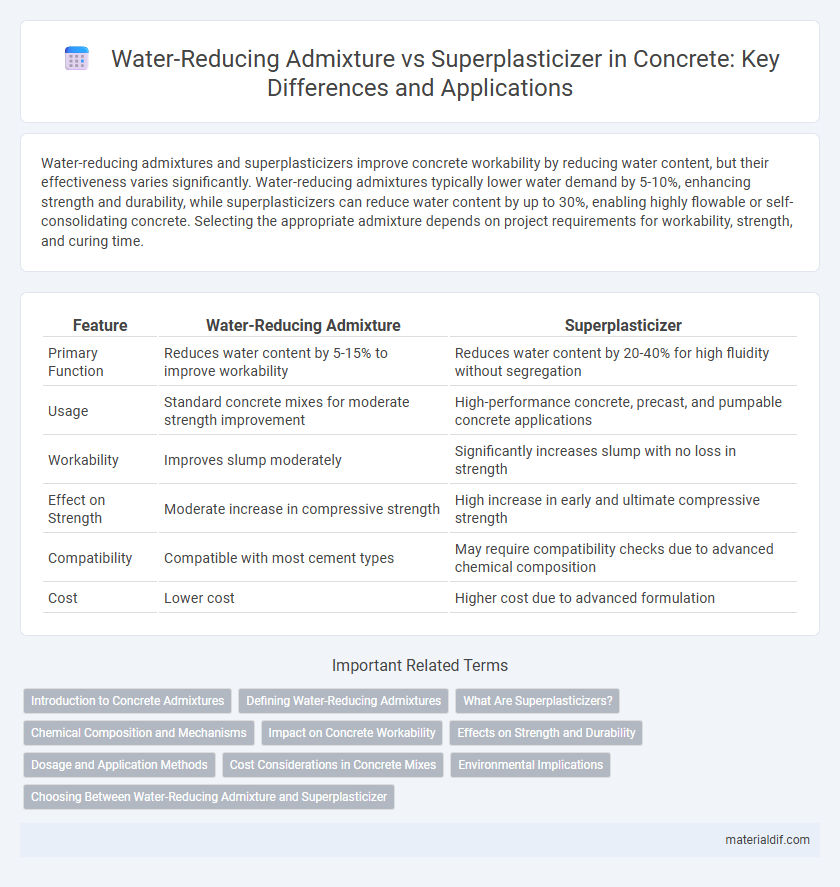

Table of Comparison

| Feature | Water-Reducing Admixture | Superplasticizer |

|---|---|---|

| Primary Function | Reduces water content by 5-15% to improve workability | Reduces water content by 20-40% for high fluidity without segregation |

| Usage | Standard concrete mixes for moderate strength improvement | High-performance concrete, precast, and pumpable concrete applications |

| Workability | Improves slump moderately | Significantly increases slump with no loss in strength |

| Effect on Strength | Moderate increase in compressive strength | High increase in early and ultimate compressive strength |

| Compatibility | Compatible with most cement types | May require compatibility checks due to advanced chemical composition |

| Cost | Lower cost | Higher cost due to advanced formulation |

Introduction to Concrete Admixtures

Water-reducing admixtures and superplasticizers are essential chemical additives in concrete technology designed to improve workability and strength without increasing water content. Water-reducing admixtures typically reduce water demand by 5-15%, enhancing concrete density and durability, while superplasticizers can reduce water content by up to 30% or more, offering superior flowability for high-performance and self-consolidating concrete. Both admixtures optimize the water-cement ratio, crucial for achieving desired mechanical properties and long-term concrete performance.

Defining Water-Reducing Admixtures

Water-reducing admixtures are chemical additives used in concrete to decrease the water content required for a given workability, enhancing strength and durability. These admixtures primarily improve the hydration process by dispersing cement particles more efficiently, resulting in a denser concrete matrix. Unlike superplasticizers, water-reducing admixtures offer moderate water reduction without significantly altering slurry viscosity.

What Are Superplasticizers?

Superplasticizers are advanced chemical admixtures designed to significantly improve the workability of concrete without increasing its water content. They reduce water-to-cement ratio, resulting in higher strength and durability while enabling easier placement and compaction. Unlike traditional water-reducing admixtures, superplasticizers can achieve water reductions of up to 30%, making them essential for high-performance and self-consolidating concrete applications.

Chemical Composition and Mechanisms

Water-reducing admixtures primarily consist of lignosulfonates or polycarboxylate ethers that work by dispersing cement particles to decrease water content and enhance workability. Superplasticizers, often based on sulfonated naphthalene or polycarboxylate polymers, achieve higher water reduction by generating electrostatic repulsion and steric hindrance among cement grains, producing superior flow characteristics. The chemical composition of superplasticizers enables a more effective break-up of cement agglomerates compared to conventional water reducers, resulting in significantly improved concrete strength and durability.

Impact on Concrete Workability

Water-reducing admixtures improve concrete workability by lowering water content while maintaining fluidity, resulting in increased strength and durability. Superplasticizers, also known as high-range water reducers, significantly enhance workability by allowing a substantial reduction in water without compromising consistency, ideal for high-performance and self-compacting concrete. Both admixtures optimize slump retention and flowability, but superplasticizers provide superior plasticity for complex formworks and dense reinforcement conditions.

Effects on Strength and Durability

Water-reducing admixtures improve concrete strength by reducing water content while maintaining workability, leading to denser and more durable structures. Superplasticizers provide a higher degree of water reduction compared to conventional water-reducers, significantly enhancing compressive strength and extending the service life by minimizing permeability and mitigating crack formation. Both admixtures contribute to durability, but superplasticizers offer superior performance in high-strength and high-performance concrete applications.

Dosage and Application Methods

Water-reducing admixtures typically require dosages ranging from 0.2% to 0.5% by cement weight, improving workability and reducing water content in concrete mixes. Superplasticizers, used at lower dosages around 0.5% to 2%, provide higher fluidity and slump retention, making them ideal for high-performance and self-compacting concrete applications. Application methods for water-reducing admixtures involve direct mixing with water or aggregates, while superplasticizers are often added after initial mixing to optimize dispersion and enhance flow characteristics.

Cost Considerations in Concrete Mixes

Water-reducing admixtures generally cost less than superplasticizers, making them a budget-friendly choice for standard concrete mixes. Superplasticizers, while more expensive, provide higher water reduction and improved workability, leading to potential savings in cement usage and enhanced concrete performance. Cost-effectiveness depends on project requirements, with superplasticizers favored in high-strength or complex mix designs despite their premium price.

Environmental Implications

Water-reducing admixtures and superplasticizers both enhance concrete workability while reducing water content, but superplasticizers offer greater efficiency, leading to stronger, more durable concrete with lower cement demand. Reduced cement usage directly decreases industrial CO2 emissions, contributing to a smaller carbon footprint in concrete production. Choosing superplasticizers supports sustainability by enabling resource conservation and lowering environmental impacts associated with cement manufacturing.

Choosing Between Water-Reducing Admixture and Superplasticizer

Choosing between water-reducing admixtures and superplasticizers depends on the desired concrete performance and project requirements. Water-reducing admixtures improve workability by reducing water content up to 10-15%, enhancing strength without significantly altering set times, while superplasticizers can reduce water content by 20-30% or more, producing highly flowable concrete suitable for complex forms or high-strength applications. Consider factors such as slump retention, setting time, cost, and compatibility with cement types to optimize concrete mix design and achieve targeted durability and strength.

Water-Reducing Admixture vs Superplasticizer Infographic

materialdif.com

materialdif.com