White Portland cement concrete offers superior aesthetic appeal with its bright, uniform color, making it ideal for architectural and decorative applications, while gray Portland cement concrete provides robust structural strength at a lower cost. The chemical composition and manufacturing process of white Portland cement reduce iron content, resulting in its distinctive color and enhanced reflectivity that can improve heat resistance and energy efficiency. Gray Portland cement concrete remains the preferred choice for most construction projects due to its durability and versatility in a wide range of environments.

Table of Comparison

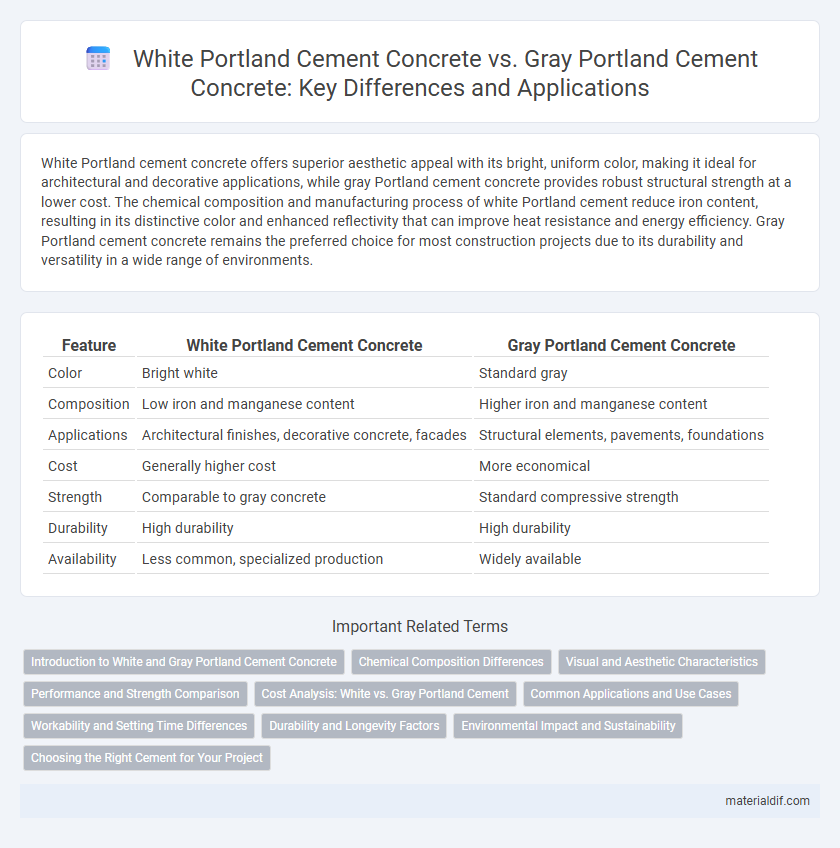

| Feature | White Portland Cement Concrete | Gray Portland Cement Concrete |

|---|---|---|

| Color | Bright white | Standard gray |

| Composition | Low iron and manganese content | Higher iron and manganese content |

| Applications | Architectural finishes, decorative concrete, facades | Structural elements, pavements, foundations |

| Cost | Generally higher cost | More economical |

| Strength | Comparable to gray concrete | Standard compressive strength |

| Durability | High durability | High durability |

| Availability | Less common, specialized production | Widely available |

Introduction to White and Gray Portland Cement Concrete

White Portland cement concrete offers high aesthetic appeal due to its bright, clean appearance, making it ideal for architectural and decorative applications. Gray Portland cement concrete is the most commonly used concrete type, prized for its strength, durability, and cost-effectiveness in structural construction. Both types utilize similar raw materials, but white cement is produced with low iron oxide content, resulting in its distinctive color and enabling enhanced design flexibility.

Chemical Composition Differences

White Portland cement concrete differs chemically from gray Portland cement concrete primarily in its reduced content of iron, manganese, and titanium oxides, which are responsible for the characteristic gray color. The white cement contains lower amounts of Fe2O3 (typically less than 0.5%) compared to gray cement, which may contain up to 5% or more of iron oxides. This reduced oxide content not only impacts coloration but also influences the hydration and durability properties of the concrete.

Visual and Aesthetic Characteristics

White Portland cement concrete offers a bright, clean appearance ideal for architectural applications requiring light or reflective surfaces, enhancing the vibrancy of pigments and stains. In contrast, gray Portland cement concrete provides a traditional, neutral tone often favored for industrial and structural projects where a consistent, understated finish is preferred. The choice between white and gray cement concrete significantly influences the visual impact, allowing designers to tailor aesthetics to specific architectural styles and environmental conditions.

Performance and Strength Comparison

White Portland cement concrete exhibits higher reflectivity and brightness due to its lower iron and manganese content, enhancing aesthetic appeal without compromising durability. Gray Portland cement concrete generally offers higher compressive strength and is preferred for structural applications where load-bearing capacity is critical. Both types provide similar durability and weather resistance, but white Portland cement concrete may have slightly lower early strength development compared to gray Portland cement concrete.

Cost Analysis: White vs. Gray Portland Cement

White Portland cement concrete typically incurs higher costs due to its specialized production processes and raw materials, leading to prices approximately 30-50% greater than gray Portland cement concrete. The increased expense is justified in applications demanding aesthetic appeal, such as architectural facades and decorative finishes. In contrast, gray Portland cement concrete remains the cost-effective choice for structural and large-scale construction projects where visual appearance is less critical.

Common Applications and Use Cases

White Portland cement concrete is commonly used in architectural and decorative applications where aesthetics are critical, such as in precast panels, terrazzo flooring, and sculptures due to its bright and clean appearance. Gray Portland cement concrete is typically utilized for structural projects like highways, bridges, and foundations because of its strength and cost-effectiveness. Both types are valued for durability, but choice depends heavily on the project's visual requirements and environmental exposure.

Workability and Setting Time Differences

White Portland cement concrete typically offers higher workability due to its finer particle size and lower gypsum content, allowing for smoother mixing and easier placement compared to gray Portland cement concrete. The setting time of white Portland cement concrete is generally longer, influenced by its purity and reduced iron and manganese oxides, which slow down the hydration process. In contrast, gray Portland cement concrete sets faster, benefiting from higher iron content that accelerates the chemical reactions during curing.

Durability and Longevity Factors

White Portland cement concrete exhibits superior durability due to its lower iron content and refined manufacturing process, resulting in enhanced resistance to chemical attacks and weathering. Gray Portland cement concrete, while widely used and cost-effective, may be more susceptible to sulfate attack and freeze-thaw cycles depending on aggregate quality and mix design. Proper curing methods and admixture selection significantly influence the longevity of both types of concrete in structural applications.

Environmental Impact and Sustainability

White Portland cement concrete produces lower carbon emissions during manufacturing compared to gray Portland cement concrete due to its raw material composition and kiln firing process. The energy-intensive production of gray Portland cement contributes significantly to global CO2 emissions, highlighting sustainability concerns in large-scale construction projects. Utilizing white Portland cement concrete can enhance environmental performance in architectural applications requiring aesthetic and sustainable solutions.

Choosing the Right Cement for Your Project

White Portland cement concrete offers enhanced aesthetic appeal with its bright, clean finish, making it ideal for decorative projects, architectural facades, and terrazzo flooring. Gray Portland cement concrete provides superior strength and is widely used in structural applications such as foundations, pavements, and bridges due to its cost-effectiveness and durability. Selecting the right cement depends on project requirements, balancing factors like appearance, strength, and budget constraints.

White Portland cement concrete vs gray Portland cement concrete Infographic

materialdif.com

materialdif.com