Fly ash concrete and slag concrete both enhance durability and sustainability by incorporating industrial by-products, but fly ash improves workability and reduces heat of hydration more effectively. Slag concrete offers superior resistance to sulfate attack and increased long-term strength due to its latent hydraulic properties. Choosing between fly ash and slag concrete depends on specific project requirements such as exposure conditions and desired mechanical performance.

Table of Comparison

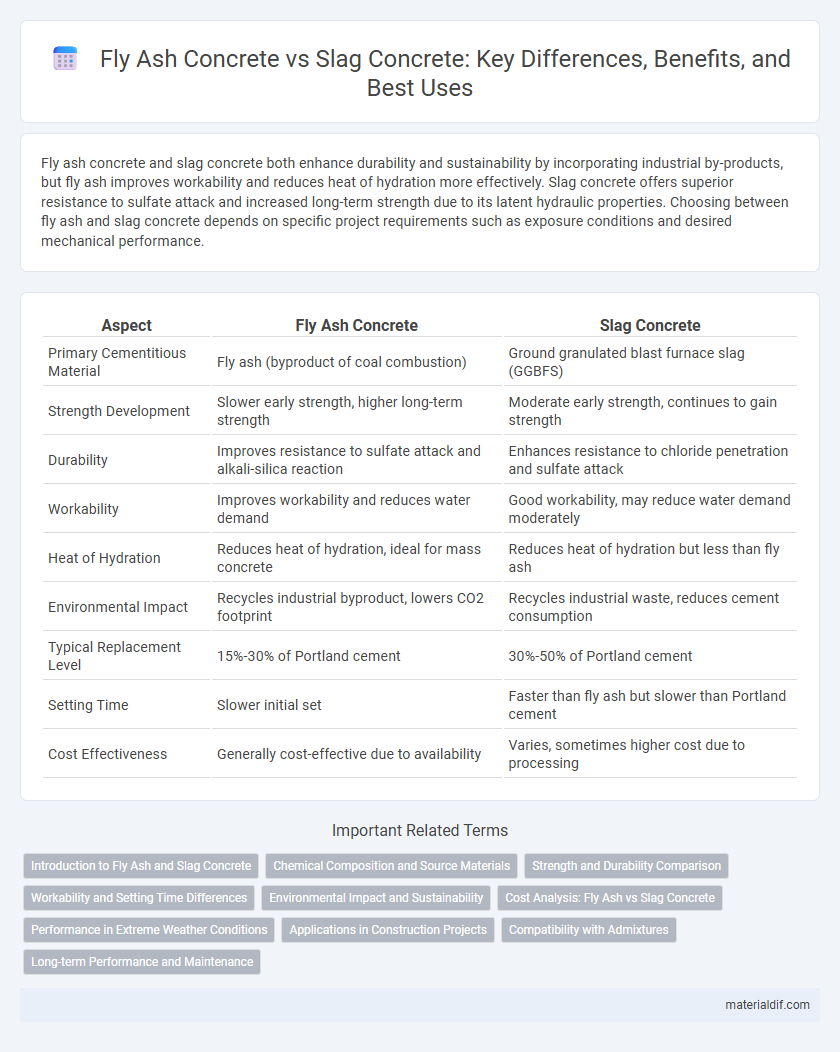

| Aspect | Fly Ash Concrete | Slag Concrete |

|---|---|---|

| Primary Cementitious Material | Fly ash (byproduct of coal combustion) | Ground granulated blast furnace slag (GGBFS) |

| Strength Development | Slower early strength, higher long-term strength | Moderate early strength, continues to gain strength |

| Durability | Improves resistance to sulfate attack and alkali-silica reaction | Enhances resistance to chloride penetration and sulfate attack |

| Workability | Improves workability and reduces water demand | Good workability, may reduce water demand moderately |

| Heat of Hydration | Reduces heat of hydration, ideal for mass concrete | Reduces heat of hydration but less than fly ash |

| Environmental Impact | Recycles industrial byproduct, lowers CO2 footprint | Recycles industrial waste, reduces cement consumption |

| Typical Replacement Level | 15%-30% of Portland cement | 30%-50% of Portland cement |

| Setting Time | Slower initial set | Faster than fly ash but slower than Portland cement |

| Cost Effectiveness | Generally cost-effective due to availability | Varies, sometimes higher cost due to processing |

Introduction to Fly Ash and Slag Concrete

Fly ash concrete incorporates byproducts of coal combustion, enhancing workability and durability while reducing cement consumption and carbon footprint. Slag concrete utilizes ground granulated blast furnace slag (GGBFS), a steel-making byproduct, which improves strength development and resistance to chemical attacks. Both materials serve as supplementary cementitious materials, optimizing sustainability and performance in modern concrete formulations.

Chemical Composition and Source Materials

Fly ash concrete utilizes fly ash, a byproduct from coal combustion in power plants, primarily composed of silica, alumina, and iron oxide, enhancing workability and durability through pozzolanic reactions. Slag concrete incorporates granulated blast furnace slag (GBFS), sourced from iron production, rich in calcium, silica, and alumina, contributing to improved strength and resistance to chemical attack. The distinct chemical compositions influence cement hydration and long-term performance, with fly ash offering slower strength gain and slag concrete providing denser microstructure development.

Strength and Durability Comparison

Fly ash concrete typically exhibits improved long-term compressive strength due to the pozzolanic reaction contributing to denser microstructure formation, while slag concrete often achieves higher early-age strength because of its latent hydraulic properties. Durability in fly ash concrete is enhanced through reduced permeability and increased resistance to sulfate attack and alkali-silica reaction, whereas slag concrete offers superior resistance to chloride penetration and carbonation. Both materials contribute to enhanced concrete durability and strength, but slag concrete is generally preferred for environments with aggressive chloride exposure, and fly ash concrete excels in sulfate-rich conditions.

Workability and Setting Time Differences

Fly ash concrete exhibits improved workability due to the spherical shape of fly ash particles, which enhance flow and reduce water demand, while slag concrete typically offers moderate workability with a denser particle structure. Fly ash concrete generally has a longer setting time as the pozzolanic reaction is slower, whereas slag concrete sets faster due to its latent hydraulic properties. These differences significantly impact construction scheduling and finishing operations in projects utilizing supplementary cementitious materials.

Environmental Impact and Sustainability

Fly ash concrete significantly reduces carbon dioxide emissions by utilizing industrial byproducts, decreasing the demand for Portland cement and lowering overall environmental impact. Slag concrete also promotes sustainability through the recycling of steel manufacturing waste, enhancing durability and reducing landfill waste. Both materials contribute to eco-friendly construction by improving resource efficiency and minimizing the carbon footprint of concrete production.

Cost Analysis: Fly Ash vs Slag Concrete

Fly ash concrete generally offers a lower material cost compared to slag concrete due to the widespread availability and lower processing expenses of fly ash. Slag concrete, while often more expensive initially, can provide enhanced durability and strength that may reduce life-cycle costs in infrastructure projects. Cost analysis must also account for factors like regional material accessibility, transportation fees, and specific project requirements to determine the most economical choice between fly ash and slag concrete.

Performance in Extreme Weather Conditions

Fly ash concrete exhibits improved resistance to freeze-thaw cycles and reduced permeability, enhancing durability in cold and wet conditions. Slag concrete provides superior sulfate attack resistance and maintains strength in high-temperature environments due to its dense microstructure. Both materials enhance concrete performance, but slag concrete is particularly advantageous in aggressive chemical exposures and extreme heat applications.

Applications in Construction Projects

Fly ash concrete is widely used in high-rise buildings, pavements, and mass concrete structures due to its improved workability, reduced heat of hydration, and enhanced durability. Slag concrete is preferred in marine structures, wastewater treatment plants, and industrial floors for its superior resistance to sulfate attack and increased long-term strength. Both materials contribute to sustainable construction by recycling industrial by-products and reducing the carbon footprint of cement production.

Compatibility with Admixtures

Fly ash concrete exhibits excellent compatibility with a wide range of chemical admixtures, enhancing workability and strength development due to its pozzolanic properties. Slag concrete reacts differently with admixtures, often requiring specific formulations to optimize setting time and durability because of the latent hydraulic nature of slag. Both materials demand careful selection of admixture types and dosages to achieve desired performance in varied environmental conditions.

Long-term Performance and Maintenance

Fly ash concrete exhibits superior long-term durability due to its enhanced resistance to sulfate attack, reduced permeability, and lower heat of hydration, which minimizes cracking over time. Slag concrete also provides excellent durability with improved freeze-thaw resistance and corrosion protection, but may require longer curing periods to achieve optimal strength. Maintenance costs for fly ash concrete tend to be lower as the material's self-healing properties reduce microcracking and subsequent repairs, while slag concrete benefits from its dense matrix that limits ingress of harmful agents, extending service life.

Fly Ash Concrete vs Slag Concrete Infographic

materialdif.com

materialdif.com