Roller-compacted concrete (RCC) offers faster construction and higher durability compared to traditional concrete pavement, making it ideal for heavy-duty applications like industrial floors and highways. RCC uses a drier mix that requires heavy compaction with rollers, reducing curing time and minimizing cracking risks. Traditional concrete pavement typically requires longer curing periods and more labor-intensive finishing processes, resulting in higher initial costs and extended project timelines.

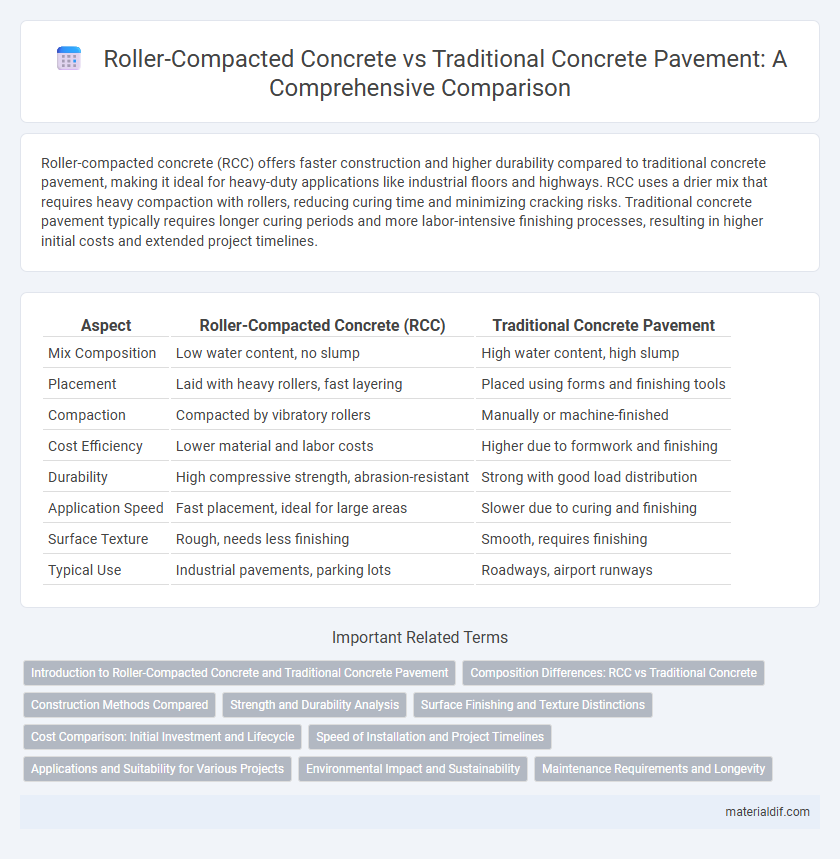

Table of Comparison

| Aspect | Roller-Compacted Concrete (RCC) | Traditional Concrete Pavement |

|---|---|---|

| Mix Composition | Low water content, no slump | High water content, high slump |

| Placement | Laid with heavy rollers, fast layering | Placed using forms and finishing tools |

| Compaction | Compacted by vibratory rollers | Manually or machine-finished |

| Cost Efficiency | Lower material and labor costs | Higher due to formwork and finishing |

| Durability | High compressive strength, abrasion-resistant | Strong with good load distribution |

| Application Speed | Fast placement, ideal for large areas | Slower due to curing and finishing |

| Surface Texture | Rough, needs less finishing | Smooth, requires finishing |

| Typical Use | Industrial pavements, parking lots | Roadways, airport runways |

Introduction to Roller-Compacted Concrete and Traditional Concrete Pavement

Roller-compacted concrete (RCC) is a dry, stiff mix placed with asphalt paving equipment and compacted by rollers, offering high strength and rapid construction for pavements. Traditional concrete pavement uses a wetter mix, poured and finished with forms and trowels to achieve smooth surfaces, providing durability and load-bearing capacity. RCC is favored for heavy-duty applications like industrial floors and dams due to its low cost and quick installation compared to conventional concrete pavement.

Composition Differences: RCC vs Traditional Concrete

Roller-Compacted Concrete (RCC) consists of a dry, zero-slump mixture with lower water content and no slump, incorporating coarse aggregates and less cement paste compared to traditional concrete. Traditional concrete pavement uses a wetter mix with higher water-to-cement ratio, enabling better flow and workability with more fine aggregates and admixtures for smooth finishing. RCC's composition emphasizes rapid placement and compaction using heavy machinery, whereas traditional concrete requires forms and manual finishing processes.

Construction Methods Compared

Roller-compacted concrete (RCC) differs from traditional concrete pavement primarily in its construction methods, as RCC uses a drier mix that is placed with earthmoving equipment and compacted by heavy rollers, enabling faster application. Traditional concrete pavement involves a wetter mix poured into forms and finished with trowels, requiring longer curing times and more labor-intensive processes. RCC construction significantly reduces time and equipment costs while providing comparable durability and strength for industrial and heavy-duty pavement projects.

Strength and Durability Analysis

Roller-compacted concrete (RCC) exhibits higher compressive strength due to its low water-cement ratio and dense aggregate packing, resulting in enhanced load-bearing capacity compared to traditional concrete pavement. The interlocking granular structure of RCC improves resistance to rutting and abrasion, contributing to superior durability under heavy traffic conditions. Research shows RCC also demonstrates lower permeability, reducing susceptibility to freeze-thaw cycles and chemical attacks, which are common durability challenges in conventional concrete pavements.

Surface Finishing and Texture Distinctions

Roller-compacted concrete (RCC) pavement features a rougher surface texture due to its dry mix and compaction method, resulting in enhanced skid resistance compared to traditional concrete pavement. Traditional concrete pavement offers a smoother finish, achieved through troweling and floating, which improves ride quality and reduces noise levels. Surface finishing in RCC emphasizes durability and rapid construction, while traditional concrete prioritizes aesthetic smoothness and precise texture control.

Cost Comparison: Initial Investment and Lifecycle

Roller-compacted concrete (RCC) typically offers a lower initial investment compared to traditional concrete pavement due to reduced material and labor costs, as it requires less cement and no forms or finishing. Lifecycle costs for RCC are also generally lower because of its high durability, reduced maintenance needs, and faster construction times that minimize traffic disruptions. Traditional concrete, while having higher upfront expenses, may incur increased lifecycle costs from more frequent repairs and longer curing periods affecting operational efficiency.

Speed of Installation and Project Timelines

Roller-compacted concrete (RCC) offers significantly faster installation compared to traditional concrete pavement due to its lower slump mix and the ability to be compacted with heavy rollers immediately after placement. This accelerated curing process reduces project timelines, enabling quicker lane reopening and minimizing traffic disruptions. RCC's rapid installation makes it an ideal choice for large-scale infrastructure projects requiring fast completion without compromising durability.

Applications and Suitability for Various Projects

Roller-compacted concrete (RCC) is ideal for large-scale infrastructure projects such as dams, industrial pavements, and heavy-duty roads due to its rapid placement and high compressive strength. Traditional concrete pavement suits urban streets, highways, and airport runways, offering superior smoothness and load-bearing capacity with conventional finishing techniques. RCC's lower cost and faster construction time make it preferable for projects with tight budgets and schedules, while traditional concrete excels in areas requiring precise surface tolerances and high durability under frequent traffic.

Environmental Impact and Sustainability

Roller-compacted concrete (RCC) significantly reduces environmental impact compared to traditional concrete pavement by using less water and cement, resulting in lower carbon emissions during production. RCC's dense, coarse mixture enhances durability and reduces maintenance needs, leading to longer pavement life and fewer resource-intensive repairs. The material's ability to incorporate industrial by-products like fly ash further improves sustainability by recycling waste and minimizing landfill use.

Maintenance Requirements and Longevity

Roller-compacted concrete (RCC) pavement requires significantly less maintenance compared to traditional concrete due to its lower permeability and higher abrasion resistance, reducing repair frequency and associated costs. RCC demonstrates enhanced longevity with a typical lifespan exceeding 30 years under heavy traffic conditions, outperforming traditional concrete pavements that often necessitate more frequent joint repairs and surface treatments. The dense, durable composition of RCC minimizes cracking and rutting, contributing to extended service life and reduced lifecycle maintenance demands.

Roller-Compacted Concrete vs Traditional Concrete Pavement Infographic

materialdif.com

materialdif.com