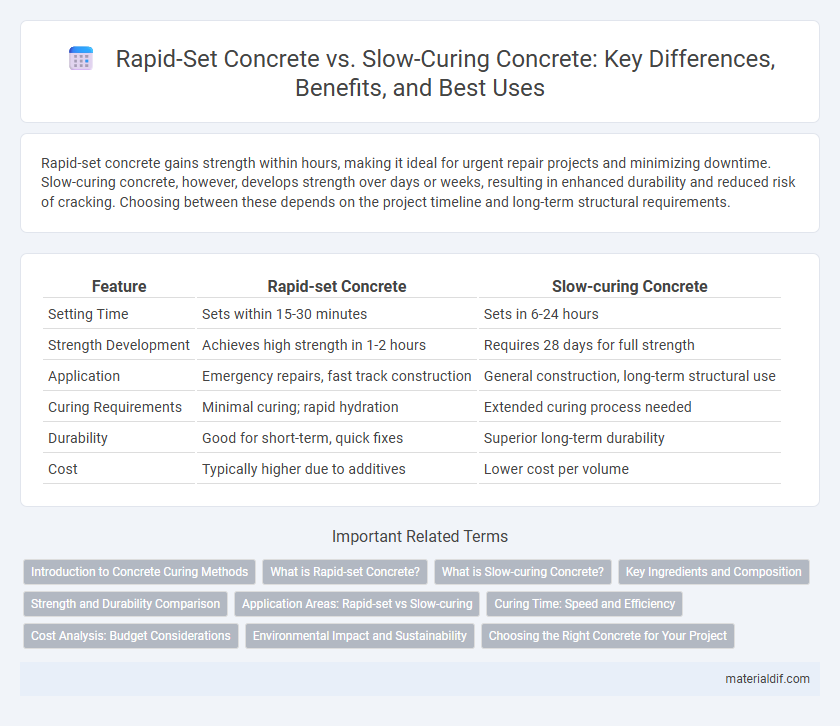

Rapid-set concrete gains strength within hours, making it ideal for urgent repair projects and minimizing downtime. Slow-curing concrete, however, develops strength over days or weeks, resulting in enhanced durability and reduced risk of cracking. Choosing between these depends on the project timeline and long-term structural requirements.

Table of Comparison

| Feature | Rapid-set Concrete | Slow-curing Concrete |

|---|---|---|

| Setting Time | Sets within 15-30 minutes | Sets in 6-24 hours |

| Strength Development | Achieves high strength in 1-2 hours | Requires 28 days for full strength |

| Application | Emergency repairs, fast track construction | General construction, long-term structural use |

| Curing Requirements | Minimal curing; rapid hydration | Extended curing process needed |

| Durability | Good for short-term, quick fixes | Superior long-term durability |

| Cost | Typically higher due to additives | Lower cost per volume |

Introduction to Concrete Curing Methods

Concrete curing methods directly impact the strength development and durability of the material. Rapid-set concrete achieves initial set within minutes by utilizing special admixtures that accelerate hydration, making it ideal for fast repairs and cold weather applications. Slow-curing concrete allows for gradual moisture retention, promoting optimal hydration and reducing the risk of cracking, thereby benefiting structural integrity in long-term construction projects.

What is Rapid-set Concrete?

Rapid-set concrete is a high-performance mixture formulated to achieve early strength gain, typically reaching usable strength within one to three hours after placement. This type of concrete incorporates specialized chemical accelerators and fine cementitious materials, enabling faster hydration and reduced curing time compared to traditional slow-curing concrete. Rapid-set concrete is ideal for urgent repairs, emergency infrastructure restoration, and projects requiring minimal downtime.

What is Slow-curing Concrete?

Slow-curing concrete refers to a type of concrete that develops strength and hardness gradually over an extended period, often taking several weeks to achieve its full durability. This process allows for enhanced hydration, improving long-term strength, durability, and resistance to cracking, making it ideal for heavy-duty construction projects. Unlike rapid-set concrete, slow-curing concrete requires controlled moisture and temperature conditions to optimize its curing performance and structural integrity.

Key Ingredients and Composition

Rapid-set concrete typically contains high early strength cement, calcium chloride accelerators, and lower water-cement ratios to promote fast hydration and curing within hours. Slow-curing concrete relies on ordinary Portland cement, balanced aggregates, and higher water content to allow gradual hydration, resulting in increased long-term strength and durability over weeks. The presence of admixtures such as retarders in slow-curing mixes contrasts with accelerators in rapid-set formulations, influencing setting time and final performance characteristics.

Strength and Durability Comparison

Rapid-set concrete achieves high early strength within hours, making it ideal for time-sensitive projects, while slow-curing concrete gains strength gradually over weeks, resulting in a denser and more durable matrix. The accelerated hydration in rapid-set mixtures can lead to increased microcracking, slightly compromising long-term durability compared to the superior chemical bonding in slow-curing concrete. For structural applications demanding maximum longevity and resistance to environmental stressors, slow-curing concrete typically offers enhanced performance.

Application Areas: Rapid-set vs Slow-curing

Rapid-set concrete is ideal for emergency repairs, road patches, and construction sites requiring quick turnaround times due to its fast strength gain within hours. Slow-curing concrete suits large structural projects like bridges and dams where gradual hydration ensures enhanced long-term durability and reduced cracking risk. Selection between rapid-set and slow-curing concrete depends primarily on project timeline, load requirements, and environmental exposure conditions.

Curing Time: Speed and Efficiency

Rapid-set concrete achieves initial set in as little as 15 minutes and reaches substantial strength within a few hours, making it ideal for time-sensitive construction projects and emergency repairs. Slow-curing concrete typically requires 28 days to reach full strength, ensuring gradual hydration that enhances long-term durability and structural integrity. Selecting between these options balances the need for immediate load-bearing capacity versus prolonged strength development for sustained performance.

Cost Analysis: Budget Considerations

Rapid-set concrete typically incurs higher upfront material costs due to specialized admixtures that accelerate curing. Slow-curing concrete generally offers lower initial expenses but may increase labor and project duration costs because of extended setting times. Evaluating total budget impact requires balancing rapid-set premium prices against potential savings from shortened construction schedules and reduced labor overhead.

Environmental Impact and Sustainability

Rapid-set concrete reduces environmental impact by minimizing curing time, which lowers energy consumption and decreases carbon emissions associated with prolonged curing processes. Slow-curing concrete, while offering increased durability and strength that can extend the lifespan of structures, tends to have a larger carbon footprint due to extended curing periods and greater water use. Sustainable construction increasingly favors rapid-set formulations that incorporate recycled materials and reduce waste, balancing performance with eco-friendly practices.

Choosing the Right Concrete for Your Project

Rapid-set concrete offers accelerated curing times, typically setting within 30 minutes to 2 hours, making it ideal for urgent repairs and time-sensitive projects. Slow-curing concrete, which can take 28 days or more to reach full strength, provides enhanced durability and reduced cracking, suitable for structural elements requiring long-term stability. Selecting between rapid-set and slow-curing concrete depends on project deadlines, load requirements, and environmental conditions to ensure optimal performance and longevity.

Rapid-set Concrete vs Slow-curing Concrete Infographic

materialdif.com

materialdif.com