Rapid-set concrete offers faster strength gain, making it ideal for quick repairs and projects with tight deadlines, while slow-cure concrete provides higher durability and long-term strength through gradual hydration. Rapid-set mixes often require less water and decrease downtime, but may be more prone to cracking without proper curing techniques. Slow-cure concrete, although taking longer to reach full strength, ensures enhanced resistance to weathering and structural stresses over time.

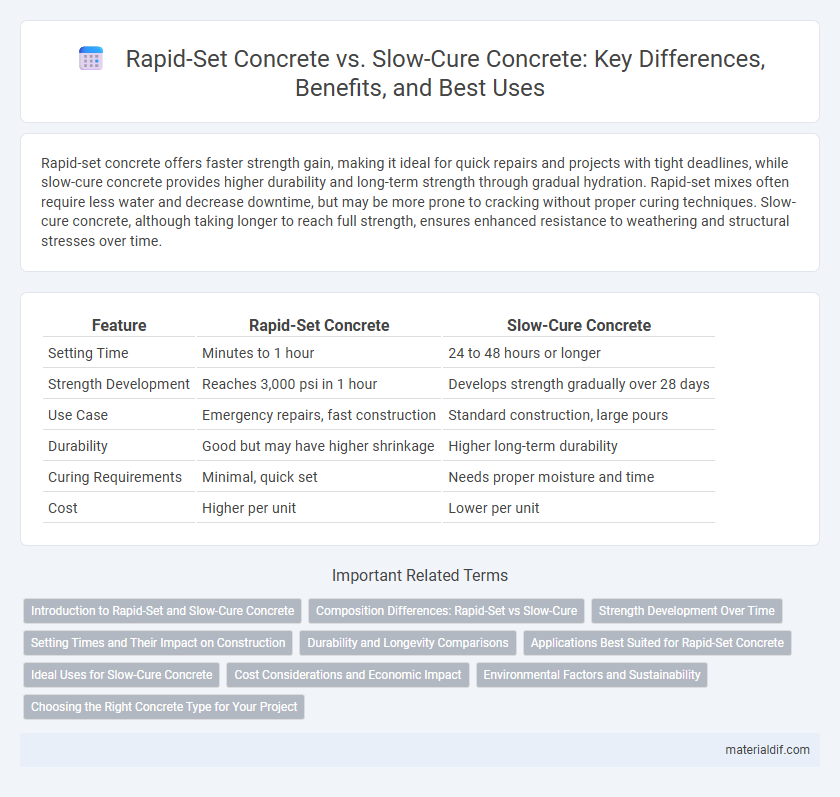

Table of Comparison

| Feature | Rapid-Set Concrete | Slow-Cure Concrete |

|---|---|---|

| Setting Time | Minutes to 1 hour | 24 to 48 hours or longer |

| Strength Development | Reaches 3,000 psi in 1 hour | Develops strength gradually over 28 days |

| Use Case | Emergency repairs, fast construction | Standard construction, large pours |

| Durability | Good but may have higher shrinkage | Higher long-term durability |

| Curing Requirements | Minimal, quick set | Needs proper moisture and time |

| Cost | Higher per unit | Lower per unit |

Introduction to Rapid-Set and Slow-Cure Concrete

Rapid-set concrete achieves initial strength within hours due to its high early cement hydration rate, making it ideal for time-sensitive projects such as emergency repairs and fast-track construction. Slow-cure concrete develops strength over days or weeks, offering enhanced long-term durability and reduced cracking risk, suitable for structural applications requiring maximum strength and longevity. Understanding the differences in curing times and performance characteristics guides optimal selection for specific construction needs.

Composition Differences: Rapid-Set vs Slow-Cure

Rapid-set concrete contains high proportions of calcium aluminate and proprietary accelerators that promote fast hydration and early strength gain within hours. Slow-cure concrete relies primarily on ordinary Portland cement, resulting in a gradual hydration process that can take days or weeks to reach full strength. The difference in chemical additives and cement types directly impacts setting times, thermal development, and final mechanical properties.

Strength Development Over Time

Rapid-set concrete achieves high early strength within 1 to 3 hours, making it ideal for time-sensitive repairs and fast-track construction projects. Slow-cure concrete, typically gaining significant strength over 28 days, offers enhanced durability and long-term performance due to gradual hydration processes. The selection between rapid-set and slow-cure concrete depends on project timelines and structural load requirements linked directly to their divergent strength development profiles.

Setting Times and Their Impact on Construction

Rapid-set concrete typically achieves initial set within 15-30 minutes, significantly reducing project downtime and enabling faster workload transitions on-site. Slow-cure concrete requires curing periods of 24 to 48 hours or more, providing greater strength development and durability but extending overall construction timelines. Choosing between rapid-set and slow-cure concrete depends on balancing immediate structural demands with long-term performance and scheduling flexibility.

Durability and Longevity Comparisons

Rapid-set concrete offers quicker strength gain, making it suitable for projects requiring fast turnaround, but it may exhibit slightly reduced long-term durability compared to slow-cure concrete due to accelerated hydration processes. Slow-cure concrete develops strength gradually, enhancing its microstructure and resulting in superior longevity and resistance to environmental stressors such as freeze-thaw cycles and chemical attacks. Choosing between rapid-set and slow-cure concrete depends on balancing immediate construction needs with desired lifespan and resilience of the structure.

Applications Best Suited for Rapid-Set Concrete

Rapid-set concrete is ideal for emergency repairs, road patching, and projects requiring minimal downtime due to its fast strength gain within hours. It suits critical infrastructure such as airport runways, bridges, and industrial floors where quick return to service is essential. This type of concrete excels in cold weather applications where traditional slow-cure concrete may not set properly.

Ideal Uses for Slow-Cure Concrete

Slow-cure concrete is ideal for large structural projects such as bridges, foundations, and dams where strength and durability over time are critical. Its extended curing process enhances compressive strength and reduces the risk of cracking, making it suitable for environments subject to heavy loads and extreme weather conditions. Slow-curing concrete also benefits decorative finishes and surface treatments by allowing better adhesion and reduced shrinkage.

Cost Considerations and Economic Impact

Rapid-set concrete typically incurs higher initial costs due to specialized additives and expedited curing technology, but it reduces labor expenses and project downtime, offering economic advantages in time-sensitive construction. Slow-cure concrete has lower material costs and provides enhanced long-term strength and durability, potentially decreasing maintenance expenses and lifecycle costs. Selecting between rapid-set and slow-cure concrete influences overall project budgets by balancing upfront investments against operational efficiency and structural longevity.

Environmental Factors and Sustainability

Rapid-set concrete significantly reduces construction time by curing in hours rather than days, decreasing site emissions and energy consumption associated with prolonged equipment use. Slow-cure concrete, while requiring extended curing periods, develops higher long-term strength and durability, potentially reducing repair frequency and material waste over the structure's lifecycle. Environmental considerations favor rapid-set concrete for immediate efficiency, whereas slow-cure concrete offers sustainability advantages through enhanced structural longevity and resilience.

Choosing the Right Concrete Type for Your Project

Rapid-set concrete offers significantly faster curing times, often reaching usable strength within hours, making it ideal for projects with tight deadlines or emergency repairs. Slow-cure concrete, although requiring days or weeks to fully harden, provides superior long-term durability and strength, suitable for large structural elements and high-load applications. Selecting the right concrete type depends on project requirements such as timeline, load-bearing needs, and environmental conditions to ensure optimal performance and longevity.

Rapid-Set Concrete vs Slow-Cure Concrete Infographic

materialdif.com

materialdif.com