Polymer concrete offers enhanced chemical resistance and durability compared to traditional epoxy concrete, making it ideal for industrial applications exposed to harsh environments. Epoxy concrete provides superior adhesive properties and flexibility, which helps prevent cracking and improves the bonding of repair materials. Both materials are valuable in construction, with polymer concrete excelling in strength and longevity, while epoxy concrete is preferred for its ease of application and repair capabilities.

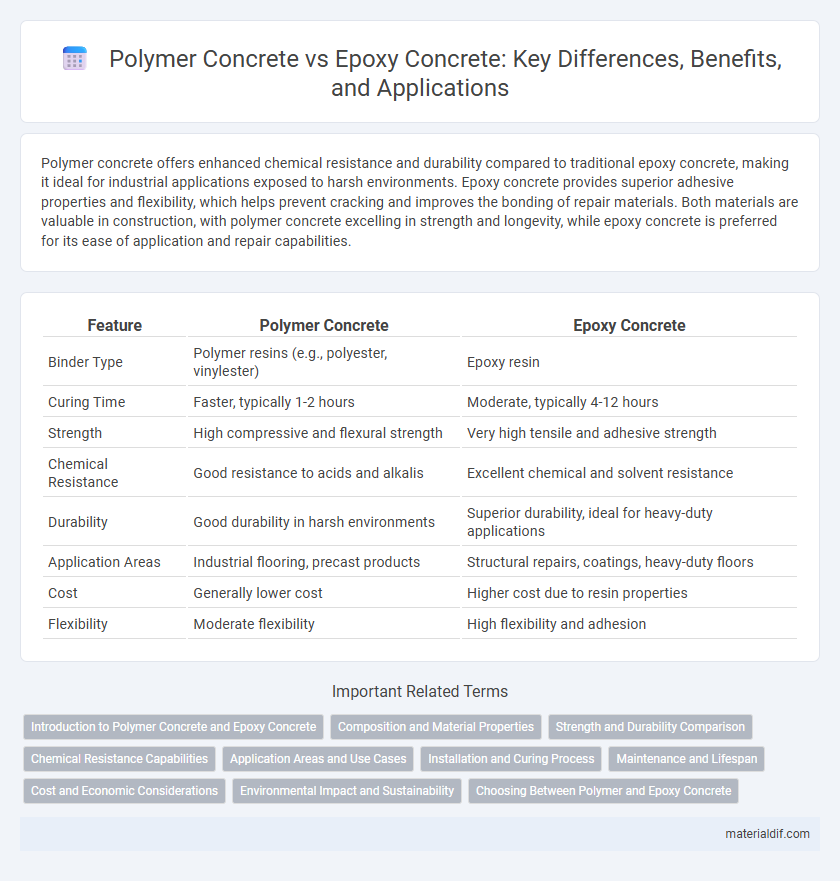

Table of Comparison

| Feature | Polymer Concrete | Epoxy Concrete |

|---|---|---|

| Binder Type | Polymer resins (e.g., polyester, vinylester) | Epoxy resin |

| Curing Time | Faster, typically 1-2 hours | Moderate, typically 4-12 hours |

| Strength | High compressive and flexural strength | Very high tensile and adhesive strength |

| Chemical Resistance | Good resistance to acids and alkalis | Excellent chemical and solvent resistance |

| Durability | Good durability in harsh environments | Superior durability, ideal for heavy-duty applications |

| Application Areas | Industrial flooring, precast products | Structural repairs, coatings, heavy-duty floors |

| Cost | Generally lower cost | Higher cost due to resin properties |

| Flexibility | Moderate flexibility | High flexibility and adhesion |

Introduction to Polymer Concrete and Epoxy Concrete

Polymer concrete is a composite material that uses polymer binders instead of cement, offering enhanced chemical resistance and rapid curing times compared to traditional concrete. Epoxy concrete incorporates epoxy resins as the binding agent, providing superior mechanical strength, adhesion, and durability, especially in industrial applications. Both materials improve performance in harsh environments but differ in composition and specific use cases, with polymer concrete favoring flexibility and epoxy concrete excelling in structural integrity.

Composition and Material Properties

Polymer concrete consists of aggregates bound together with a polymer binder, typically polyester or vinyl ester resins, providing superior chemical resistance and reduced curing times compared to traditional concretes. Epoxy concrete utilizes epoxy resins as a binder, resulting in exceptional adhesion, high tensile strength, and enhanced durability against abrasion and corrosion. Both materials offer improved mechanical properties over conventional concrete, but epoxy concrete is often favored for applications requiring high strength and chemical resistance, while polymer concrete excels in rapid curing and corrosion resistance.

Strength and Durability Comparison

Polymer concrete exhibits superior compressive strength and chemical resistance compared to epoxy concrete, making it ideal for heavy-load-bearing applications and harsh environments. Epoxy concrete offers excellent adhesion and crack resistance but tends to have lower tensile strength and less long-term durability under UV exposure and moisture. The enhanced mechanical properties of polymer concrete result in a longer service life and reduced maintenance costs in industrial and infrastructural projects.

Chemical Resistance Capabilities

Polymer concrete demonstrates superior chemical resistance against acids, alkalis, and solvents due to its polymer binder matrix, which prevents degradation and enhances durability in harsh environments. Epoxy concrete also offers strong chemical resistance, particularly against oils and fuels, but may show vulnerability to certain acids and prolonged exposure to UV light. Selecting the appropriate concrete type depends on the specific chemical exposure conditions and required longevity in industrial or infrastructure applications.

Application Areas and Use Cases

Polymer concrete is widely used in infrastructure projects such as bridge decks, parking structures, and precast elements due to its high compressive strength and chemical resistance. Epoxy concrete excels in industrial flooring, wastewater treatment plants, and chemical containment areas where superior adhesion and abrasion resistance are critical. Both materials offer durability, but polymer concrete is preferred for load-bearing structures while epoxy concrete is chosen for environments requiring strong chemical bonding and surface protection.

Installation and Curing Process

Polymer concrete features a faster installation and curing process due to the use of polymer resins that chemically harden at room temperature, allowing for quicker project turnaround times compared to epoxy concrete. Epoxy concrete requires meticulous surface preparation and controlled temperature conditions during installation to ensure optimal bonding and curing, which can extend the overall curing period. Both materials demand precise mixing ratios and curing environments to achieve their respective mechanical strengths and durability.

Maintenance and Lifespan

Polymer concrete offers superior chemical resistance and lower permeability, resulting in reduced maintenance needs and a longer lifespan in harsh environments. Epoxy concrete provides excellent adhesion and high mechanical strength but may require more frequent inspections due to potential UV degradation and brittleness over time. Selecting polymer concrete often leads to lower lifecycle costs compared to epoxy-based alternatives in demanding industrial applications.

Cost and Economic Considerations

Polymer concrete typically incurs higher upfront costs due to expensive polymer resins but offers long-term savings with superior durability and chemical resistance. Epoxy concrete, while often more affordable initially, may require more frequent repairs and maintenance, increasing lifecycle expenses. Evaluating total cost of ownership, including installation, maintenance, and service life, is essential for economically sound decision-making between these materials.

Environmental Impact and Sustainability

Polymer concrete uses synthetic resins as binders, which often involve non-renewable petrochemical resources and present challenges in biodegradability and recyclability, impacting its environmental footprint. Epoxy concrete, while offering superior mechanical properties and chemical resistance, relies heavily on epoxy resins derived from bisphenol-A (BPA), raising concerns about toxicity and limited sustainability. Sustainable practices in concrete production emphasize minimizing volatile organic compounds (VOCs) emissions, improving material recyclability, and developing bio-based polymers to reduce ecological impact.

Choosing Between Polymer and Epoxy Concrete

Polymer concrete offers superior chemical resistance and faster curing times, making it ideal for environments exposed to aggressive chemicals or requiring rapid project completion. Epoxy concrete provides exceptional adhesive strength and durability, suitable for structural repairs and high-load applications where bonding performance is critical. Selecting between polymer and epoxy concrete depends on specific project demands such as exposure conditions, curing time constraints, and mechanical strength requirements.

Polymer Concrete vs Epoxy Concrete Infographic

materialdif.com

materialdif.com