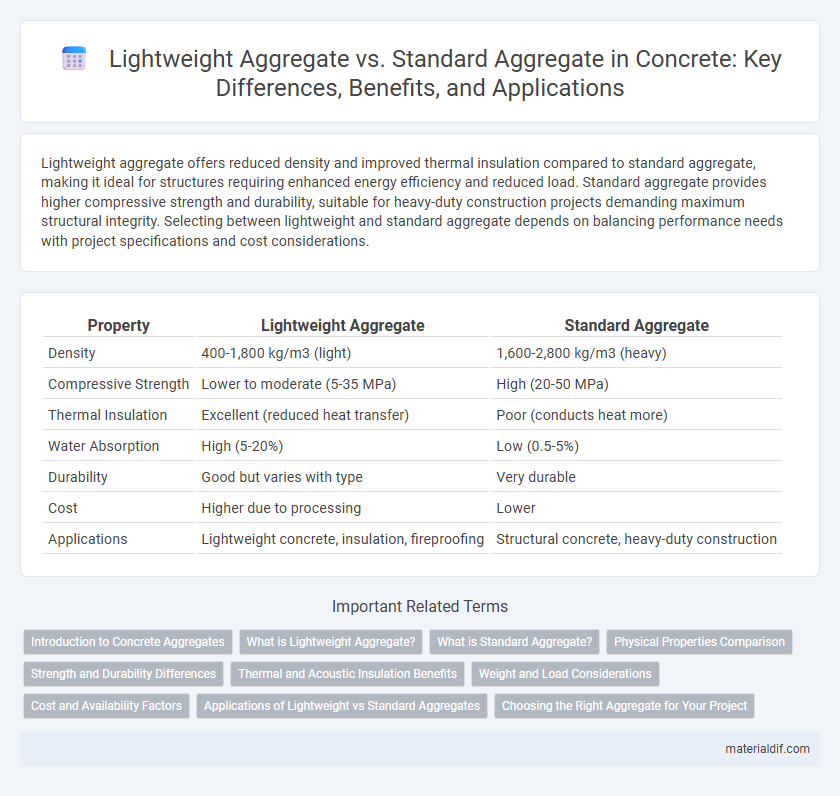

Lightweight aggregate offers reduced density and improved thermal insulation compared to standard aggregate, making it ideal for structures requiring enhanced energy efficiency and reduced load. Standard aggregate provides higher compressive strength and durability, suitable for heavy-duty construction projects demanding maximum structural integrity. Selecting between lightweight and standard aggregate depends on balancing performance needs with project specifications and cost considerations.

Table of Comparison

| Property | Lightweight Aggregate | Standard Aggregate |

|---|---|---|

| Density | 400-1,800 kg/m3 (light) | 1,600-2,800 kg/m3 (heavy) |

| Compressive Strength | Lower to moderate (5-35 MPa) | High (20-50 MPa) |

| Thermal Insulation | Excellent (reduced heat transfer) | Poor (conducts heat more) |

| Water Absorption | High (5-20%) | Low (0.5-5%) |

| Durability | Good but varies with type | Very durable |

| Cost | Higher due to processing | Lower |

| Applications | Lightweight concrete, insulation, fireproofing | Structural concrete, heavy-duty construction |

Introduction to Concrete Aggregates

Lightweight aggregates, derived from expanded clay, shale, or slate, offer reduced density and improved thermal insulation compared to standard aggregates like gravel and crushed stone. Standard aggregates provide higher compressive strength and durability, making them suitable for heavy structural applications in concrete construction. Understanding the distinct properties and benefits of each aggregate type is essential for optimizing concrete mix design based on project requirements.

What is Lightweight Aggregate?

Lightweight aggregate refers to naturally occurring or manufactured materials such as expanded clay, shale, or slate that have a lower density than standard aggregate, typically ranging from 0.6 to 1.2 g/cm3. These aggregates improve concrete's thermal insulation, reduce dead load, and enhance fire resistance while maintaining adequate strength for structural applications. Compared to standard aggregates which are denser and heavier, lightweight aggregates produce concrete with improved workability and reduced overall weight, making them ideal for high-rise buildings and bridge decks.

What is Standard Aggregate?

Standard aggregate refers to natural or crushed materials such as gravel, sand, and crushed stone commonly used in concrete production to provide strength, durability, and stability. These materials have higher density and weight compared to lightweight aggregates, which directly influences the concrete's compressive strength and load-bearing capacity. Standard aggregates typically range from 600 to 1800 kg/m3 in density and are essential for structural concrete applications where maximum strength is required.

Physical Properties Comparison

Lightweight aggregate exhibits a lower density, typically ranging from 0.9 to 1.6 g/cm3, compared to standard aggregate's density of 2.4 to 2.9 g/cm3, resulting in reduced dead load in concrete structures. Porosity in lightweight aggregates often exceeds 20%, enhancing thermal insulation and reducing water absorption, while standard aggregates have minimal porosity. Compressive strength of lightweight aggregate concrete normally ranges between 17 to 35 MPa, which is lower than the 25 to 50 MPa commonly found in standard aggregate concrete.

Strength and Durability Differences

Lightweight aggregate concrete typically exhibits lower compressive strength than standard aggregate concrete due to the porous nature of lightweight aggregates like expanded clay or shale. However, lightweight aggregate provides enhanced durability through improved freeze-thaw resistance and reduced thermal conductivity, making it suitable for specific structural applications. Standard aggregates such as crushed stone or gravel offer higher density and strength but may be more prone to cracking under thermal or moisture cycles compared to lightweight alternatives.

Thermal and Acoustic Insulation Benefits

Lightweight aggregate concrete significantly enhances thermal insulation due to its lower density and higher porosity, reducing heat transfer and improving energy efficiency in buildings. It also offers superior acoustic insulation by absorbing sound waves more effectively than standard aggregate concrete, minimizing noise transmission. These insulation benefits make lightweight aggregate a preferred choice for structures requiring improved environmental comfort and energy savings.

Weight and Load Considerations

Lightweight aggregate typically weighs between 800 to 1,600 kg/m3, significantly reducing the overall concrete density compared to standard aggregates that range from 1,600 to 2,400 kg/m3. This reduction in weight lowers dead loads on structures, enabling more efficient design of foundations and supporting elements. Load considerations must account for changes in strength and stiffness, as lightweight aggregate concrete often exhibits lower compressive strength but improved thermal insulation and fire resistance.

Cost and Availability Factors

Lightweight aggregate costs generally exceed those of standard aggregate due to specialized manufacturing and limited natural sources. Availability of lightweight aggregate varies regionally, often requiring importation, which further increases expenses and lead times. Standard aggregate benefits from widespread accessibility and abundant supply, resulting in lower costs and easier procurement for large-scale concrete projects.

Applications of Lightweight vs Standard Aggregates

Lightweight aggregates are ideal for applications requiring reduced structural load, such as in high-rise buildings, precast panels, and bridge decks, due to their lower density and improved thermal insulation properties. Standard aggregates are preferred for high-strength concrete in heavy-duty applications like foundations, pavements, and industrial floors where durability and compressive strength are critical. The choice between lightweight and standard aggregates impacts not only the structural performance but also the thermal efficiency and overall weight of the concrete structure.

Choosing the Right Aggregate for Your Project

Lightweight aggregate offers superior thermal insulation and reduced structural load compared to standard aggregate, making it ideal for high-rise buildings and energy-efficient constructions. Standard aggregate provides higher compressive strength and cost-effectiveness, suitable for most general-purpose concrete applications. Selecting the right aggregate depends on project requirements such as load-bearing capacity, thermal performance, and budget constraints.

Lightweight Aggregate vs Standard Aggregate Infographic

materialdif.com

materialdif.com