Roller-compacted concrete (RCC) offers rapid construction with minimal formwork by using a dry mix compacted with rollers, ideal for large-scale pavements and dams. Slip-form concrete relies on continuous pouring and a moving form to create smooth, uniform surfaces, commonly used in roadways and bridges. Choosing between RCC and slip-form depends on project speed, surface finish requirements, and load-bearing demands.

Table of Comparison

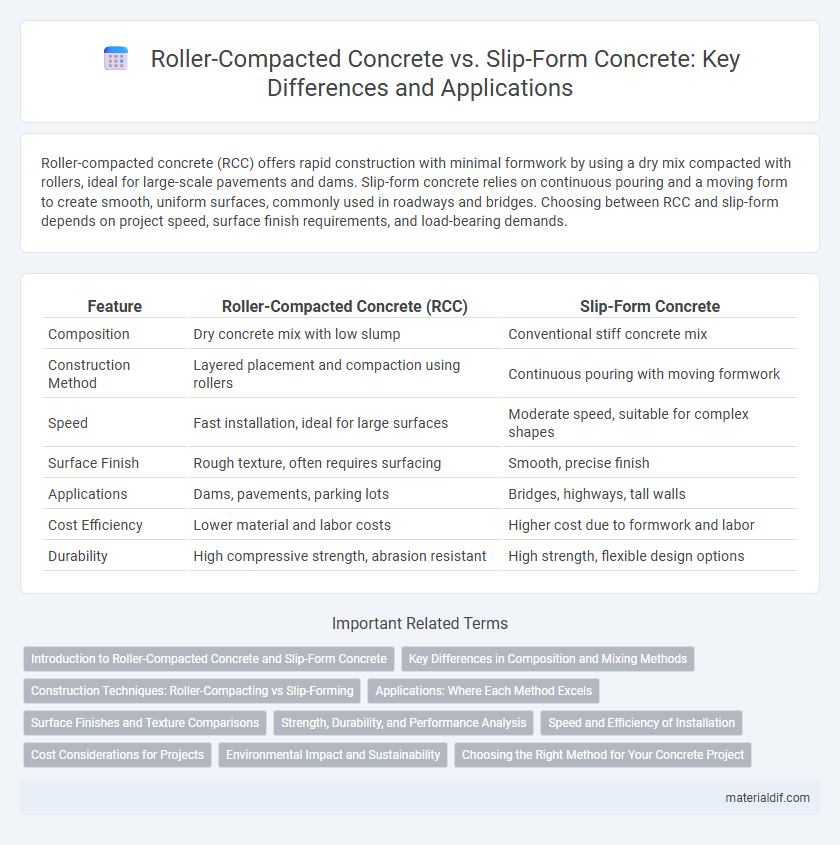

| Feature | Roller-Compacted Concrete (RCC) | Slip-Form Concrete |

|---|---|---|

| Composition | Dry concrete mix with low slump | Conventional stiff concrete mix |

| Construction Method | Layered placement and compaction using rollers | Continuous pouring with moving formwork |

| Speed | Fast installation, ideal for large surfaces | Moderate speed, suitable for complex shapes |

| Surface Finish | Rough texture, often requires surfacing | Smooth, precise finish |

| Applications | Dams, pavements, parking lots | Bridges, highways, tall walls |

| Cost Efficiency | Lower material and labor costs | Higher cost due to formwork and labor |

| Durability | High compressive strength, abrasion resistant | High strength, flexible design options |

Introduction to Roller-Compacted Concrete and Slip-Form Concrete

Roller-compacted concrete (RCC) is a stiff, dry concrete mixture placed and compacted with heavy rollers, commonly used for large-scale infrastructure like dams and pavements, offering high strength and rapid construction. Slip-form concrete involves continuous pouring and shaping of concrete using a moving formwork system, ideal for vertical structures such as highways, bridge decks, and tunnels. Both methods optimize efficiency and durability but differ significantly in placement techniques and typical applications within the construction industry.

Key Differences in Composition and Mixing Methods

Roller-compacted concrete (RCC) features a low-slump, zero-slump consistency using a drier mixture composed primarily of cement, aggregates, and minimal water, optimized for heavy compaction and rapid strength gain. Slip-form concrete employs a more fluid mix with higher water content and admixtures, allowing continuous shaping and finishing via slip-forming machines. The key difference lies in RCC's stiff, dry mix applied with rollers for layered compaction, contrasting with slip-form's wetter mix enabling smooth, continuous placement and shaping.

Construction Techniques: Roller-Compacting vs Slip-Forming

Roller-compacted concrete (RCC) involves placing a drier concrete mix and compacting it with heavy rollers, offering rapid construction and high density suitable for pavements and dams. Slip-form concrete uses a continuously moving form to shape and finish concrete, ideal for vertical structures like highways and bridge rails. RCC prioritizes speed and strength with compaction, while slip-forming emphasizes smooth, continuous shaping and surface finish.

Applications: Where Each Method Excels

Roller-compacted concrete (RCC) is ideal for large-scale infrastructure projects such as dam bases, pavements, and industrial floors due to its rapid placement and high durability under heavy loads. Slip-form concrete excels in creating continuous, smooth vertical structures like bridge piers, highway barriers, and silos because of its efficient, automated forming process that ensures uniformity and speed. Each method's application depends on project requirements for volume, shape complexity, and structural demands.

Surface Finishes and Texture Comparisons

Roller-compacted concrete (RCC) typically features a rougher, more textured surface due to its dry consistency and compaction method, making it ideal for industrial pavements requiring high durability and skid resistance. Slip-form concrete, by contrast, produces smoother finishes with uniform textures suitable for architectural applications and highway curbs, achieved through continuous forming and finishing processes. The choice between RCC and slip-form concrete significantly impacts surface aesthetics, texture uniformity, and maintenance requirements based on project specifications.

Strength, Durability, and Performance Analysis

Roller-Compacted Concrete (RCC) offers high compressive strength and excellent durability due to its low water-cement ratio and dense matrix, making it ideal for large-scale infrastructure projects. Slip-Form Concrete, with its continuous pouring process, provides superior surface finish, structural integrity, and enhanced performance under dynamic loads. Comparative analysis shows RCC excels in wear resistance and cost-efficiency, while Slip-Form concrete demonstrates better flexural strength and is preferred for vertical structures requiring precise shaping.

Speed and Efficiency of Installation

Roller-compacted concrete (RCC) offers faster installation due to its dry mix and heavy compaction method, enabling large-scale pavement projects to be completed quickly with minimal curing time. Slip-form concrete uses a continuous pouring and forming process ideal for complex shapes like curbs and highways, optimizing efficiency by reducing formwork labor and allowing uninterrupted workflow. RCC excels in projects prioritizing rapid, large-area coverage, while slip-form concrete provides precision and steady progress in applications requiring intricate design and structural uniformity.

Cost Considerations for Projects

Roller-Compacted Concrete (RCC) offers significant cost savings due to lower material and labor expenses compared to Slip-Form Concrete, especially in large-scale infrastructure projects like dams and pavements. Slip-Form Concrete, while more expensive with higher formwork and skilled labor costs, provides superior finish quality and structural precision ideal for vertical and complex structures such as bridges and high-rise buildings. Project budgets must weigh RCC's durability and rapid placement against Slip-Form's enhanced aesthetic and dimensional control to optimize overall economic efficiency.

Environmental Impact and Sustainability

Roller-Compacted Concrete (RCC) reduces environmental impact through lower cement content and minimal formwork, resulting in decreased CO2 emissions and resource use compared to Slip-Form Concrete. Slip-Form Concrete typically requires more energy-intensive formwork and curing processes, increasing its environmental footprint. RCC's rapid installation and reduced water demand contribute to enhanced sustainability in large-scale infrastructure projects.

Choosing the Right Method for Your Concrete Project

Roller-Compacted Concrete (RCC) offers rapid placement and cost efficiency ideal for large-scale pavements and dam construction, while Slip-Form Concrete excels in creating smooth, continuous surfaces such as highways and bridge decks. The decision depends on project requirements like surface finish, structural design, and time constraints, with RCC favoring heavy-duty applications and Slip-Form suited for precision shaping. Evaluating factors such as equipment availability, labor skills, and environmental conditions ensures optimal selection between RCC and Slip-Form methods for durable, high-performance concrete projects.

Roller-Compacted Concrete vs Slip-Form Concrete Infographic

materialdif.com

materialdif.com