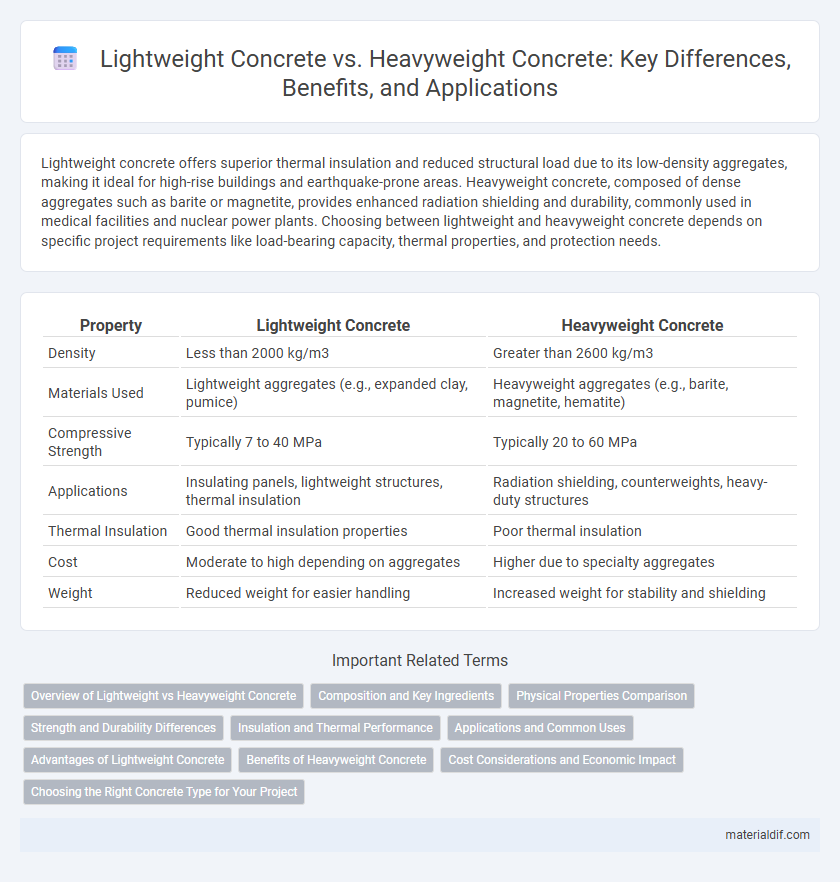

Lightweight concrete offers superior thermal insulation and reduced structural load due to its low-density aggregates, making it ideal for high-rise buildings and earthquake-prone areas. Heavyweight concrete, composed of dense aggregates such as barite or magnetite, provides enhanced radiation shielding and durability, commonly used in medical facilities and nuclear power plants. Choosing between lightweight and heavyweight concrete depends on specific project requirements like load-bearing capacity, thermal properties, and protection needs.

Table of Comparison

| Property | Lightweight Concrete | Heavyweight Concrete |

|---|---|---|

| Density | Less than 2000 kg/m3 | Greater than 2600 kg/m3 |

| Materials Used | Lightweight aggregates (e.g., expanded clay, pumice) | Heavyweight aggregates (e.g., barite, magnetite, hematite) |

| Compressive Strength | Typically 7 to 40 MPa | Typically 20 to 60 MPa |

| Applications | Insulating panels, lightweight structures, thermal insulation | Radiation shielding, counterweights, heavy-duty structures |

| Thermal Insulation | Good thermal insulation properties | Poor thermal insulation |

| Cost | Moderate to high depending on aggregates | Higher due to specialty aggregates |

| Weight | Reduced weight for easier handling | Increased weight for stability and shielding |

Overview of Lightweight vs Heavyweight Concrete

Lightweight concrete features a lower density, typically ranging from 1,440 to 1,840 kg/m3, making it ideal for reducing structural load and enhancing thermal insulation. Heavyweight concrete has a density exceeding 2,400 kg/m3, often incorporating heavy aggregates like barite or magnetite to provide radiation shielding and improved durability. The selection between lightweight and heavyweight concrete depends on specific project requirements such as load reduction, fire resistance, or radiation protection.

Composition and Key Ingredients

Lightweight concrete primarily consists of expanded clay, shale, or pumice aggregates, which reduce its density and improve thermal insulation properties. Heavyweight concrete incorporates dense aggregates such as barite, magnetite, or iron ore to increase its mass and radiation shielding capabilities. The selection of aggregates directly influences the concrete's structural density, strength, and specific application suitability.

Physical Properties Comparison

Lightweight concrete exhibits lower density, typically ranging from 1,400 to 1,800 kg/m3, compared to heavyweight concrete which ranges from 2,200 to 3,800 kg/m3. The reduced density of lightweight concrete results in improved thermal insulation and lower dead load on structures, while heavyweight concrete offers superior radiation shielding and higher compressive strength, often exceeding 50 MPa. Porosity in lightweight concrete is higher, contributing to increased air content and decreased durability relative to the dense, compact microstructure of heavyweight concrete.

Strength and Durability Differences

Lightweight concrete typically has lower compressive strength ranging from 4,000 to 6,000 psi compared to heavyweight concrete, which can exceed 8,000 psi, making heavyweight concrete preferable for structures demanding high load-bearing capacity. Durability in heavyweight concrete is enhanced by its dense aggregate composition, providing superior resistance to abrasion and impact, while lightweight concrete offers improved thermal insulation but is more prone to surface wear. The choice between lightweight and heavyweight concrete depends on balancing strength requirements and longevity against factors like thermal performance and structural load.

Insulation and Thermal Performance

Lightweight concrete offers superior insulation and enhanced thermal performance due to its low density and porous structure, which effectively reduces heat transfer. In contrast, heavyweight concrete, with its higher density and solid composition, provides limited insulation but excels in thermal mass, absorbing and slowly releasing heat to stabilize indoor temperatures. Selecting between these concretes depends on the specific insulation needs and thermal regulation goals of a construction project.

Applications and Common Uses

Lightweight concrete is commonly used in building construction for non-load-bearing walls, insulation, and precast panels due to its reduced density and improved thermal properties. Heavyweight concrete is ideal for radiation shielding in medical facilities, counterweights in bridges, and underwater structures because of its high density and enhanced durability. Both types serve specialized roles in civil engineering, with lightweight concrete prioritizing insulation and ease of handling, while heavyweight concrete focuses on strength and protection against radiation.

Advantages of Lightweight Concrete

Lightweight concrete offers superior thermal insulation and reduces the overall structure's dead load, enhancing seismic performance and lowering foundation costs. Its lower density improves handling and speeds up construction, while maintaining adequate compressive strength for many structural applications. This makes lightweight concrete an ideal choice for high-rise buildings, long-span bridges, and precast elements where weight reduction is critical.

Benefits of Heavyweight Concrete

Heavyweight concrete offers superior radiation shielding and enhanced durability, making it ideal for nuclear power plants and medical facilities. Its high density also improves structural stability, reducing vibration and noise transmission in critical infrastructure. This type of concrete provides greater fire resistance and long-term strength compared to lightweight alternatives.

Cost Considerations and Economic Impact

Lightweight concrete typically offers cost savings due to reduced material usage and lower transportation expenses, positively impacting project budgets. Heavyweight concrete incurs higher costs driven by denser aggregates and increased handling requirements, which can increase overall construction expenses. Selecting the appropriate concrete type depends on balancing upfront material costs with long-term economic benefits related to structural performance and project needs.

Choosing the Right Concrete Type for Your Project

Lightweight concrete, with its lower density ranging from 800 to 1,600 kg/m3, offers advantages such as improved thermal insulation and reduced structural load, making it ideal for high-rise buildings and precast elements. Heavyweight concrete, typically exceeding 2,400 kg/m3 due to the inclusion of dense aggregates like barite or magnetite, provides superior radiation shielding and durability, suitable for medical facilities and nuclear power plants. Selecting the right concrete type depends on project requirements related to load-bearing capacity, thermal properties, and environmental resistance.

Lightweight Concrete vs Heavyweight Concrete Infographic

materialdif.com

materialdif.com