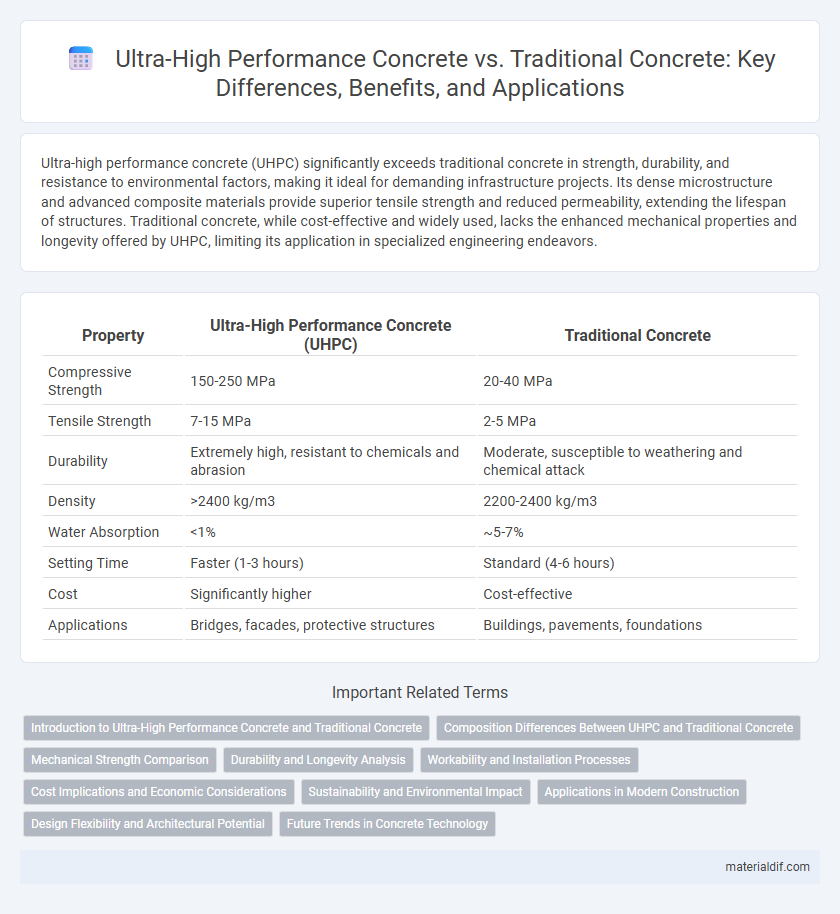

Ultra-high performance concrete (UHPC) significantly exceeds traditional concrete in strength, durability, and resistance to environmental factors, making it ideal for demanding infrastructure projects. Its dense microstructure and advanced composite materials provide superior tensile strength and reduced permeability, extending the lifespan of structures. Traditional concrete, while cost-effective and widely used, lacks the enhanced mechanical properties and longevity offered by UHPC, limiting its application in specialized engineering endeavors.

Table of Comparison

| Property | Ultra-High Performance Concrete (UHPC) | Traditional Concrete |

|---|---|---|

| Compressive Strength | 150-250 MPa | 20-40 MPa |

| Tensile Strength | 7-15 MPa | 2-5 MPa |

| Durability | Extremely high, resistant to chemicals and abrasion | Moderate, susceptible to weathering and chemical attack |

| Density | >2400 kg/m3 | 2200-2400 kg/m3 |

| Water Absorption | <1% | ~5-7% |

| Setting Time | Faster (1-3 hours) | Standard (4-6 hours) |

| Cost | Significantly higher | Cost-effective |

| Applications | Bridges, facades, protective structures | Buildings, pavements, foundations |

Introduction to Ultra-High Performance Concrete and Traditional Concrete

Ultra-High Performance Concrete (UHPC) offers significantly enhanced mechanical properties and durability compared to Traditional Concrete, incorporating fine powders, high-strength fibers, and low water-to-cement ratios for superior compressive strength exceeding 150 MPa. Traditional Concrete, widely used in construction, is composed of cement, water, sand, and coarse aggregates, typically achieving compressive strengths between 20 and 40 MPa. UHPC's dense microstructure and optimized mix design result in exceptional resistance to abrasion, chemical attack, and environmental degradation, making it ideal for infrastructure requiring extended service life.

Composition Differences Between UHPC and Traditional Concrete

Ultra-High Performance Concrete (UHPC) distinguishes itself from traditional concrete primarily through its optimized composition, incorporating fine powders like silica fume and quartz flour to enhance particle packing and reduce porosity. UHPC also uses a higher cementitious content combined with advanced chemical admixtures and steel fibers, delivering superior tensile strength and durability compared to the coarse aggregates and lower cement content found in traditional concrete mixtures. The microstructure of UHPC results in increased density and reduced permeability, making it ideal for applications demanding extreme mechanical performance and longevity.

Mechanical Strength Comparison

Ultra-High Performance Concrete (UHPC) exhibits compressive strengths exceeding 150 MPa, significantly surpassing traditional concrete's typical range of 20-40 MPa. The enhanced mechanical strength of UHPC results from its optimized particle packing, low water-to-cement ratio, and inclusion of steel fibers, which improve tensile strength and durability. This superior performance makes UHPC ideal for applications requiring high load-bearing capacity and long service life, such as bridge decks and protective structures.

Durability and Longevity Analysis

Ultra-High Performance Concrete (UHPC) demonstrates significantly superior durability and longevity compared to traditional concrete, exhibiting exceptional resistance to chemical attacks, freeze-thaw cycles, and abrasion due to its dense microstructure and optimized particle packing. UHPC's reduced porosity minimizes water ingress, thereby enhancing its lifespan in harsh environmental conditions and reducing maintenance costs over time. In contrast, traditional concrete typically shows increased susceptibility to cracking and degradation, resulting in shorter service life and higher repair frequency.

Workability and Installation Processes

Ultra-High Performance Concrete (UHPC) exhibits superior workability compared to traditional concrete due to its finely graded materials and optimized particle packing, allowing for easier placement and consolidation without segregation. The advanced rheological properties of UHPC enable more precise installation methods, including complex formworks and thin sections, reducing labor time and improving surface finishes. In contrast, traditional concrete often requires more vibration and finishing efforts to achieve desired compaction and surface quality.

Cost Implications and Economic Considerations

Ultra-High Performance Concrete (UHPC) typically incurs higher initial costs due to specialized materials and production techniques compared to traditional concrete, but its superior durability and reduced maintenance needs offer long-term economic benefits. The extended lifespan and enhanced mechanical properties of UHPC can lead to lower life-cycle costs in infrastructure projects, making it a cost-effective choice despite the upfront investment. Evaluating total cost of ownership is crucial when comparing UHPC with traditional concrete for budget planning and asset management.

Sustainability and Environmental Impact

Ultra-High Performance Concrete (UHPC) offers superior durability and strength, significantly extending the lifespan of structures and reducing the need for frequent repairs and replacements, thereby lowering the overall carbon footprint compared to Traditional Concrete. UHPC incorporates supplementary cementitious materials and optimized mix designs that reduce cement content, a primary source of CO2 emissions in traditional concrete production. Its enhanced impermeability minimizes maintenance-related environmental impacts, making UHPC a more sustainable choice for long-term construction projects.

Applications in Modern Construction

Ultra-High Performance Concrete (UHPC) offers superior strength, durability, and reduced porosity compared to Traditional Concrete, making it ideal for demanding applications such as bridge decks, high-rise buildings, and infrastructure exposed to harsh environments. UHPC enables thinner, lighter structural elements with extended lifespans, significantly enhancing seismic resistance and reducing maintenance costs. Traditional Concrete remains prevalent for general construction but lacks the advanced mechanical properties and longevity benefits critical for cutting-edge architectural and infrastructure projects.

Design Flexibility and Architectural Potential

Ultra-High Performance Concrete (UHPC) offers superior design flexibility and architectural potential compared to Traditional Concrete due to its exceptional strength, ductility, and durability. UHPC enables the creation of thinner, more intricate structural elements and complex geometric shapes that are unachievable with conventional mixtures. This advanced material allows architects to realize innovative designs with enhanced aesthetic appeal and longevity, pushing the boundaries of modern construction.

Future Trends in Concrete Technology

Ultra-High Performance Concrete (UHPC) represents the future of concrete technology with its superior strength, durability, and sustainability compared to traditional concrete. Innovations in nano-modification, fiber reinforcement, and self-healing properties are driving increased adoption of UHPC in infrastructure and architectural applications. Research continues to optimize cost efficiency and environmental impact, positioning UHPC as a key material in resilient and smart construction systems.

Ultra-High Performance Concrete vs Traditional Concrete Infographic

materialdif.com

materialdif.com