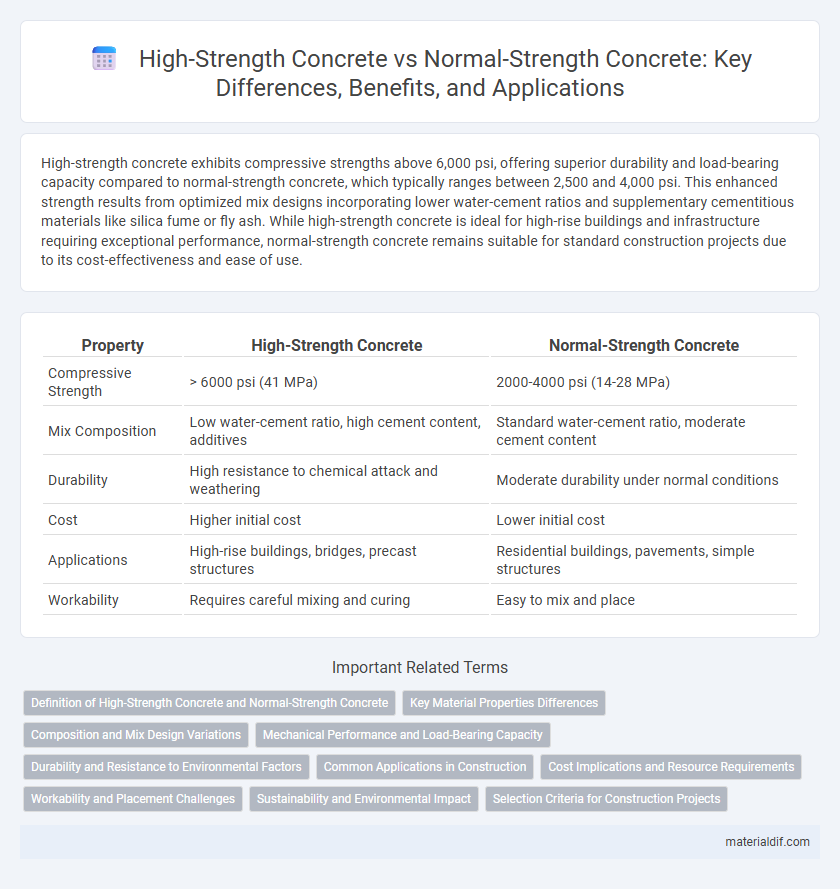

High-strength concrete exhibits compressive strengths above 6,000 psi, offering superior durability and load-bearing capacity compared to normal-strength concrete, which typically ranges between 2,500 and 4,000 psi. This enhanced strength results from optimized mix designs incorporating lower water-cement ratios and supplementary cementitious materials like silica fume or fly ash. While high-strength concrete is ideal for high-rise buildings and infrastructure requiring exceptional performance, normal-strength concrete remains suitable for standard construction projects due to its cost-effectiveness and ease of use.

Table of Comparison

| Property | High-Strength Concrete | Normal-Strength Concrete |

|---|---|---|

| Compressive Strength | > 6000 psi (41 MPa) | 2000-4000 psi (14-28 MPa) |

| Mix Composition | Low water-cement ratio, high cement content, additives | Standard water-cement ratio, moderate cement content |

| Durability | High resistance to chemical attack and weathering | Moderate durability under normal conditions |

| Cost | Higher initial cost | Lower initial cost |

| Applications | High-rise buildings, bridges, precast structures | Residential buildings, pavements, simple structures |

| Workability | Requires careful mixing and curing | Easy to mix and place |

Definition of High-Strength Concrete and Normal-Strength Concrete

High-strength concrete (HSC) is defined by its compressive strength exceeding 6,000 psi (41 MPa), achieved through a low water-cement ratio, use of high-quality materials, and advanced curing techniques. Normal-strength concrete typically has a compressive strength ranging from 2,500 to 4,000 psi (17 to 28 MPa), formulated for general construction purposes where extreme load-bearing capacity is not required. The distinction in compositional properties and curing processes directly influences the mechanical performance and durability of both concrete types.

Key Material Properties Differences

High-strength concrete typically exhibits compressive strengths above 6000 psi, surpassing normal-strength concrete, which ranges from 2500 to 5000 psi. The enhanced performance is due to a denser microstructure achieved through lower water-cement ratios, advanced admixtures, and optimized aggregate grading. Differences in modulus of elasticity and durability properties also contribute to high-strength concrete's superior load-bearing capacity and resistance to environmental stressors.

Composition and Mix Design Variations

High-strength concrete typically incorporates a lower water-to-cement ratio, higher cement content, and supplementary cementitious materials such as silica fume or fly ash, which enhance its compressive strength and durability compared to normal-strength concrete. The aggregate grading in high-strength concrete is more optimized to reduce voids and improve packing density, while normal-strength concrete uses a more conventional aggregate distribution. Admixtures like superplasticizers are commonly added in high-strength concrete mixes to maintain workability despite reduced water content, distinguishing its mix design significantly from that of normal-strength concrete.

Mechanical Performance and Load-Bearing Capacity

High-strength concrete exhibits superior mechanical performance with compressive strengths typically exceeding 6000 psi, compared to normal-strength concrete, which ranges from 2500 to 5000 psi. This enhanced strength results in significantly higher load-bearing capacity, enabling the construction of taller, more slender structures with improved durability and resistance to environmental stressors. The denser microstructure of high-strength concrete also contributes to better tensile strength and reduced permeability, increasing overall structural integrity and lifespan.

Durability and Resistance to Environmental Factors

High-strength concrete exhibits superior durability compared to normal-strength concrete due to its lower permeability and enhanced microstructure, which significantly reduces the ingress of water, chlorides, and aggressive chemicals. This improved resistance to environmental factors such as freeze-thaw cycles, sulfate attack, and carbonation ensures longer service life and reduced maintenance costs in infrastructure exposed to harsh conditions. Normal-strength concrete, while adequate for many applications, is more susceptible to cracking and deterioration when subjected to extreme environmental stresses.

Common Applications in Construction

High-strength concrete, characterized by compressive strengths exceeding 6,000 psi (41 MPa), is commonly used in high-rise buildings, bridges, and infrastructure requiring enhanced durability and load-bearing capacity. Normal-strength concrete, with strengths between 2,500 to 4,000 psi (17 to 28 MPa), is widely applied in residential buildings, pavements, and sidewalks where standard structural performance is sufficient. The selection between high-strength and normal-strength concrete depends on specific construction demands such as load, environmental conditions, and project scale.

Cost Implications and Resource Requirements

High-strength concrete demands higher-quality raw materials such as low water-cement ratios, specialized admixtures, and often supplementary cementitious materials, which increase initial costs compared to normal-strength concrete. Construction projects utilizing high-strength concrete benefit from reduced structural member sizes and lower volume requirements, potentially offsetting material expenses through savings in formwork, transportation, and overall project duration. However, the resource-intensive production process and stringent quality control for high-strength concrete often lead to higher energy consumption and labor costs, impacting the total economic feasibility against conventional normal-strength mixes.

Workability and Placement Challenges

High-strength concrete typically exhibits lower workability compared to normal-strength concrete due to its reduced water-to-cement ratio and higher cement content, complicating mixing and handling processes. Its dense microstructure increases resistance to flow, often requiring superplasticizers or advanced admixtures to enhance workability and ease placement in complex formworks or congested reinforcement areas. Normal-strength concrete offers better workability but may lack the mechanical performance and durability demands addressed by high-strength formulations in specialized construction applications.

Sustainability and Environmental Impact

High-strength concrete significantly reduces material usage and structural weight, lowering the carbon footprint compared to normal-strength concrete. Its enhanced durability extends the lifespan of constructions, minimizing repair and replacement frequency, which contributes to long-term environmental sustainability. However, the production of high-strength concrete often requires higher cement content, which may increase initial CO2 emissions unless supplemented with sustainable additives like fly ash or slag.

Selection Criteria for Construction Projects

High-strength concrete, with compressive strengths exceeding 6,000 psi, is ideal for projects requiring enhanced durability, reduced structural elements, and resistance to harsh environments, while normal-strength concrete, typically ranging from 2,500 to 4,000 psi, suits general construction with standard load requirements. Selection criteria include load-bearing capacity, environmental exposure, structural design complexity, and cost considerations, where high-strength concrete offers superior performance at higher costs. Project specifications such as seismic load, lifespan expectations, and material availability also influence the optimal choice between high-strength and normal-strength concrete.

High-Strength Concrete vs Normal-Strength Concrete Infographic

materialdif.com

materialdif.com