White concrete offers a brighter, more aesthetically versatile finish compared to traditional gray concrete, making it ideal for architectural projects requiring a clean, modern look. It is created using white Portland cement and light-colored aggregates, resulting in a higher reflectivity that helps reduce heat absorption in urban environments. Gray concrete remains the most common type due to its cost-effectiveness and strength, suitable for structural applications where appearance is less critical.

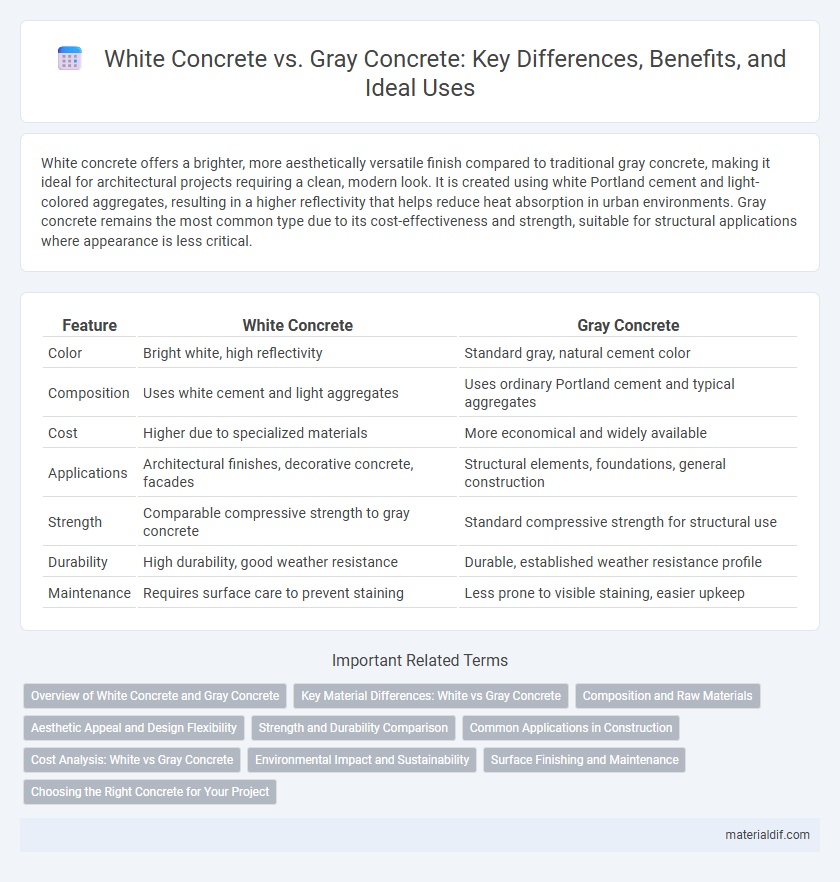

Table of Comparison

| Feature | White Concrete | Gray Concrete |

|---|---|---|

| Color | Bright white, high reflectivity | Standard gray, natural cement color |

| Composition | Uses white cement and light aggregates | Uses ordinary Portland cement and typical aggregates |

| Cost | Higher due to specialized materials | More economical and widely available |

| Applications | Architectural finishes, decorative concrete, facades | Structural elements, foundations, general construction |

| Strength | Comparable compressive strength to gray concrete | Standard compressive strength for structural use |

| Durability | High durability, good weather resistance | Durable, established weather resistance profile |

| Maintenance | Requires surface care to prevent staining | Less prone to visible staining, easier upkeep |

Overview of White Concrete and Gray Concrete

White concrete is composed of white Portland cement and light-colored aggregates, offering a clean, bright appearance ideal for architectural and decorative applications. Gray concrete, made from ordinary Portland cement and natural aggregates, is the most common type used in construction due to its cost-effectiveness and structural strength. Both types provide durable solutions but are chosen based on aesthetic preferences and specific project requirements.

Key Material Differences: White vs Gray Concrete

White concrete uses white Portland cement and light-colored aggregates, resulting in higher reflectivity and aesthetic versatility compared to gray concrete, which relies on traditional gray Portland cement and darker aggregates. The chemical composition of white cement contains lower amounts of iron and manganese oxides, preventing the gray pigments that define standard concrete. These material differences influence curing times, strength, and color consistency, making white concrete preferred for architectural applications where appearance is critical.

Composition and Raw Materials

White concrete is composed primarily of white cement, quartz or other light-colored aggregates, and minimal iron oxide, resulting in its bright appearance. Gray concrete uses ordinary Portland cement with darker aggregates such as crushed stone or gravel, containing higher levels of iron and manganese oxides that give it its characteristic gray color. The choice of raw materials directly influences the color, strength, and durability of the final concrete product.

Aesthetic Appeal and Design Flexibility

White concrete offers superior aesthetic appeal with its bright, clean appearance that enhances architectural details and provides a modern, sleek finish. Its versatility allows for greater design flexibility, enabling diverse color treatments, textures, and decorative applications that gray concrete cannot easily achieve. Gray concrete, while more traditional and cost-effective, often limits creative expression due to its uniform and muted color palette.

Strength and Durability Comparison

White concrete typically demonstrates comparable compressive strength to gray concrete, often ranging between 3,000 and 5,000 psi depending on the mix design. Its durability is enhanced by the use of white cement, which reduces the risk of staining and corrosion, making it ideal for architectural applications exposed to harsh weather conditions. Gray concrete, reinforced with standard Portland cement, generally offers robust durability and strength but may be more susceptible to surface wear and color fading over time.

Common Applications in Construction

White concrete is frequently used in architectural projects where aesthetic appeal and enhanced reflectivity are crucial, such as in decorative facades, pavements, and interior flooring. Gray concrete remains the standard choice for structural applications including foundations, bridges, and highways due to its strength and cost-effectiveness. Both types serve essential functions in construction depending on the design requirements and environmental considerations of the project.

Cost Analysis: White vs Gray Concrete

White concrete typically costs 20-30% more than gray concrete due to the use of white Portland cement and additional pigments required to achieve its bright appearance. Gray concrete benefits from mass production and readily available materials, making it a more economical choice for large-scale projects. Maintenance and longevity costs tend to be similar, but the upfront price difference often dictates selection based on budget constraints.

Environmental Impact and Sustainability

White concrete reflects more sunlight due to its higher albedo, reducing urban heat island effects and lowering cooling energy consumption compared to gray concrete. The production of white concrete often requires higher amounts of white Portland cement, which can lead to increased CO2 emissions, whereas gray concrete generally uses standard cement with a lower environmental footprint. Incorporating supplementary cementitious materials like fly ash or slag in both white and gray concrete improves sustainability by reducing cement content and associated carbon emissions.

Surface Finishing and Maintenance

White concrete offers a smoother, more refined surface finish compared to gray concrete, making it ideal for architectural applications that demand aesthetic appeal. Its lighter color helps mask surface imperfections but requires regular sealing to prevent staining and discoloration. Gray concrete typically has a rougher texture, providing better slip resistance and requiring less frequent maintenance, though it may show wear and tear more visibly over time.

Choosing the Right Concrete for Your Project

White concrete offers superior aesthetic appeal and better heat reflection, making it ideal for decorative or high-visibility projects. Gray concrete is more economical, provides excellent durability, and suits structural and foundational applications where color is less critical. Selecting the right concrete depends on project requirements such as appearance, budget, and environmental performance.

White Concrete vs Gray Concrete Infographic

materialdif.com

materialdif.com