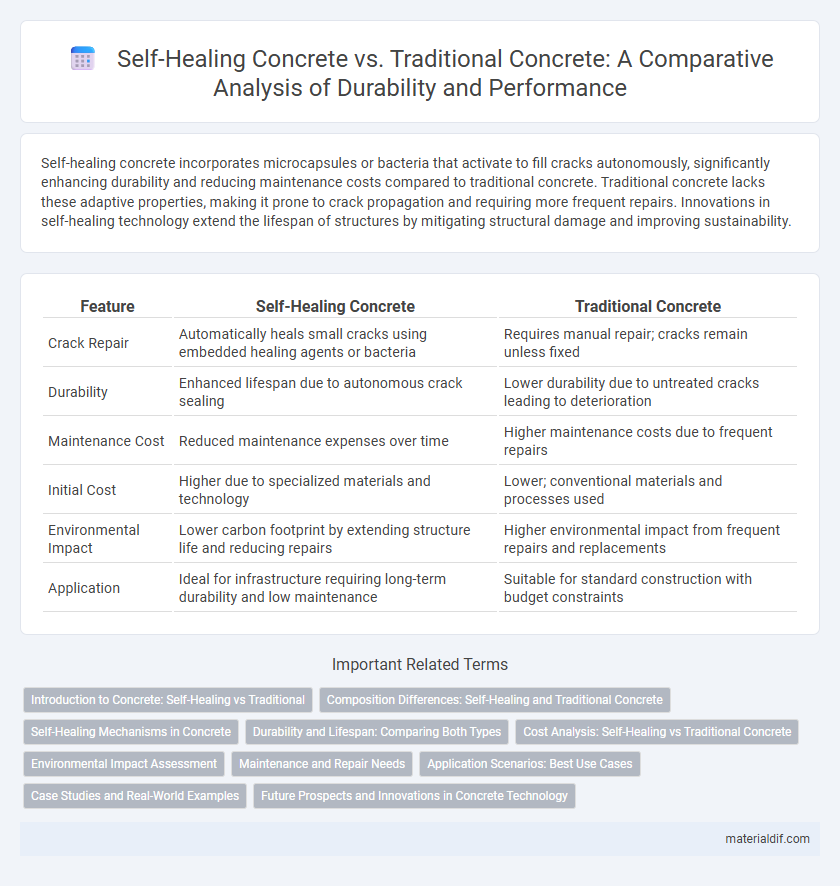

Self-healing concrete incorporates microcapsules or bacteria that activate to fill cracks autonomously, significantly enhancing durability and reducing maintenance costs compared to traditional concrete. Traditional concrete lacks these adaptive properties, making it prone to crack propagation and requiring more frequent repairs. Innovations in self-healing technology extend the lifespan of structures by mitigating structural damage and improving sustainability.

Table of Comparison

| Feature | Self-Healing Concrete | Traditional Concrete |

|---|---|---|

| Crack Repair | Automatically heals small cracks using embedded healing agents or bacteria | Requires manual repair; cracks remain unless fixed |

| Durability | Enhanced lifespan due to autonomous crack sealing | Lower durability due to untreated cracks leading to deterioration |

| Maintenance Cost | Reduced maintenance expenses over time | Higher maintenance costs due to frequent repairs |

| Initial Cost | Higher due to specialized materials and technology | Lower; conventional materials and processes used |

| Environmental Impact | Lower carbon footprint by extending structure life and reducing repairs | Higher environmental impact from frequent repairs and replacements |

| Application | Ideal for infrastructure requiring long-term durability and low maintenance | Suitable for standard construction with budget constraints |

Introduction to Concrete: Self-Healing vs Traditional

Self-healing concrete incorporates bacteria or capsules that trigger repair mechanisms to seal cracks autonomously, significantly enhancing durability and reducing maintenance costs compared to traditional concrete. Traditional concrete relies on passive resistance to cracks but lacks the ability to repair itself, leading to structural vulnerabilities over time. Advances in material science enable self-healing concrete to extend infrastructure lifespan by preventing water ingress and corrosion, addressing critical limitations of conventional concrete.

Composition Differences: Self-Healing and Traditional Concrete

Self-healing concrete incorporates specialized additives such as bacteria spores or microcapsules containing healing agents, which activate upon cracking to repair damage autonomously. Traditional concrete mainly consists of cement, water, sand, and coarse aggregates without any embedded healing mechanisms. The distinct composition of self-healing concrete enhances durability and reduces maintenance by sealing microcracks naturally, unlike traditional concrete that requires manual repairs.

Self-Healing Mechanisms in Concrete

Self-healing concrete incorporates innovative mechanisms like microcapsules, bacteria, or shape-memory materials to autonomously repair cracks, enhancing durability and reducing maintenance costs. Traditional concrete lacks these self-repairing capabilities, leading to increased susceptibility to structural damage and decreased lifespan. Advances in self-healing concrete technology significantly improve crack resistance and extend the service life of infrastructure by promoting autonomous crack closure and strength restoration.

Durability and Lifespan: Comparing Both Types

Self-healing concrete significantly enhances durability by autonomously repairing microcracks, reducing water infiltration, and preventing corrosion of reinforcement steel, which extends the lifespan beyond 50 years compared to traditional concrete's average 25-30 years. Traditional concrete relies heavily on external maintenance to address cracks, making it more susceptible to structural damage and reduced service life. Advanced materials in self-healing concrete promote longevity, lower repair costs, and sustainable infrastructure development.

Cost Analysis: Self-Healing vs Traditional Concrete

Self-healing concrete reduces long-term maintenance costs by autonomously repairing cracks, extending the lifespan of structures and minimizing expensive repairs. Initial costs of self-healing concrete are higher than traditional concrete due to specialized materials and technology, but savings accumulate through fewer structural failures and lower inspection needs. Cost-benefit analysis shows that self-healing concrete offers significant economic advantages in infrastructure projects with high durability demands.

Environmental Impact Assessment

Self-healing concrete significantly reduces environmental impact by minimizing the need for frequent repairs and lowering the consumption of raw materials like cement and aggregates, which are associated with high carbon emissions. Traditional concrete requires more regular maintenance, leading to increased energy use and waste generation throughout the structure's lifecycle. Life cycle assessments (LCA) demonstrate that self-healing concrete lowers carbon footprint and resource depletion, promoting sustainable construction practices.

Maintenance and Repair Needs

Self-healing concrete significantly reduces maintenance and repair costs by autonomously sealing microcracks, preventing water infiltration and structural deterioration. Traditional concrete requires frequent inspections and costly repairs due to crack propagation and corrosion of reinforcement steel. The enhanced durability of self-healing concrete extends the lifespan of infrastructure, minimizing downtime and resource expenditure.

Application Scenarios: Best Use Cases

Self-healing concrete is ideal for infrastructure exposed to harsh environmental conditions, such as bridges, tunnels, and marine structures, where crack repair is crucial to prolong lifespan and reduce maintenance costs. Traditional concrete remains suitable for standard construction projects with lower risk of damage, like residential buildings and sidewalks. Self-healing concrete is particularly beneficial in applications requiring enhanced durability and sustainability, minimizing downtime and repair interventions in critical structures.

Case Studies and Real-World Examples

Case studies demonstrate that self-healing concrete significantly reduces maintenance costs and extends lifespan compared to traditional concrete, as seen in the Netherlands' use of bacteria-based self-healing concrete for bridge repairs. Real-world examples include the Delta Works project's application of capsule-based self-healing concrete, resulting in reduced crack propagation and improved durability under harsh marine conditions. These implementations highlight self-healing concrete's potential to enhance infrastructure resilience and sustainability over conventional concrete materials.

Future Prospects and Innovations in Concrete Technology

Self-healing concrete represents a significant advancement over traditional concrete by incorporating microcapsules and bacteria that autonomously repair cracks, reducing maintenance costs and enhancing structural durability. Emerging innovations focus on integrating nanomaterials and advanced sensors to monitor and extend the lifespan of concrete infrastructure in real-time. Future prospects include sustainable materials and eco-friendly additives, which aim to minimize carbon footprints while improving performance and resilience in construction projects.

Self-Healing Concrete vs Traditional Concrete Infographic

materialdif.com

materialdif.com