Hydraulic cement sets and hardens through chemical reactions with water, allowing it to cure underwater and providing exceptional durability in wet conditions. Non-hydraulic cement relies on air drying for hardening and cannot set underwater, making it unsuitable for moisture-prone environments. The choice between hydraulic and non-hydraulic cement significantly impacts the performance and longevity of concrete structures in various applications.

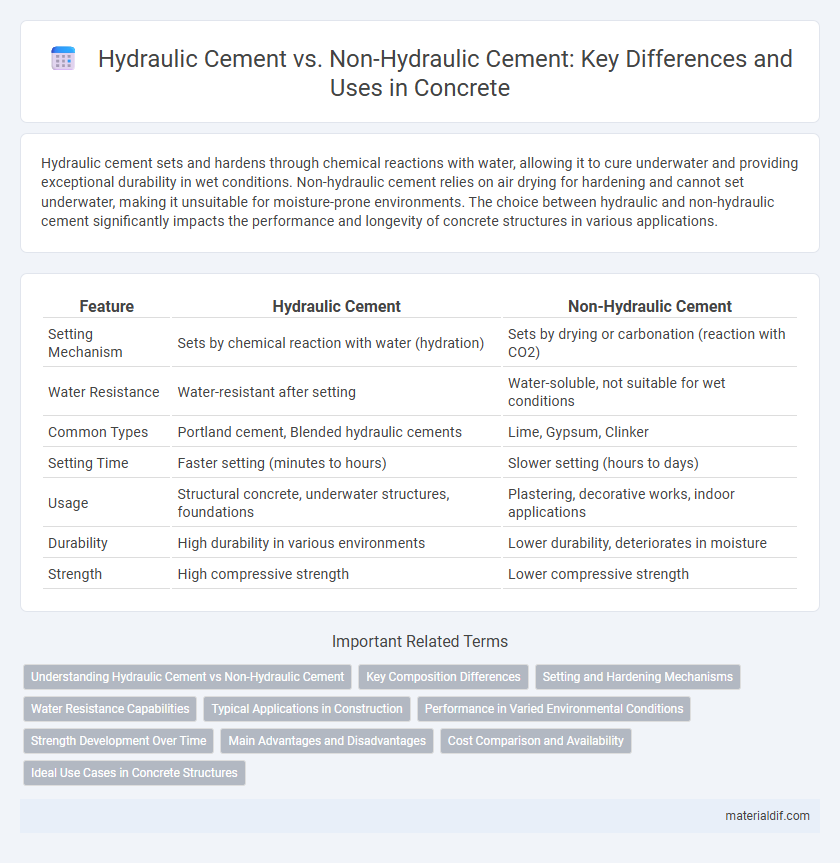

Table of Comparison

| Feature | Hydraulic Cement | Non-Hydraulic Cement |

|---|---|---|

| Setting Mechanism | Sets by chemical reaction with water (hydration) | Sets by drying or carbonation (reaction with CO2) |

| Water Resistance | Water-resistant after setting | Water-soluble, not suitable for wet conditions |

| Common Types | Portland cement, Blended hydraulic cements | Lime, Gypsum, Clinker |

| Setting Time | Faster setting (minutes to hours) | Slower setting (hours to days) |

| Usage | Structural concrete, underwater structures, foundations | Plastering, decorative works, indoor applications |

| Durability | High durability in various environments | Lower durability, deteriorates in moisture |

| Strength | High compressive strength | Lower compressive strength |

Understanding Hydraulic Cement vs Non-Hydraulic Cement

Hydraulic cement sets and hardens through a chemical reaction with water, making it suitable for wet or underwater environments, whereas non-hydraulic cement hardens by drying and requires air exposure to cure. Portland cement and slag cement are common types of hydraulic cements used in concrete construction for their durability and water resistance. Lime putty and gypsum plaster represent non-hydraulic cements, often applied in repairs and finishes where moisture exposure is minimal.

Key Composition Differences

Hydraulic cement contains compounds such as tricalcium silicate and dicalcium silicate that react with water to form a hard, durable matrix capable of setting under water. Non-hydraulic cement primarily consists of calcium hydroxide and must dry in air to harden, lacking the ability to set in wet conditions. The distinct chemical compositions directly influence their performance, with hydraulic cement favored for structural applications exposed to moisture due to its water-resistant properties.

Setting and Hardening Mechanisms

Hydraulic cement sets and hardens through a chemical reaction with water called hydration, enabling it to cure underwater and gain strength rapidly. Non-hydraulic cement relies on air drying and carbonation for setting, which prolongs the hardening process and requires exposure to CO2 to achieve strength. The hydration process in hydraulic cement forms stable compounds like calcium silicate hydrate (C-S-H), critical for structural integrity and durability in concrete applications.

Water Resistance Capabilities

Hydraulic cement sets and hardens through a chemical reaction with water, making it highly water-resistant and ideal for underwater or damp environments such as foundations and sewage systems. Non-hydraulic cement requires air to cure, limiting its water resistance and rendering it unsuitable for submerged applications or areas with constant moisture exposure. The water-resistant properties of hydraulic cement are due to its ability to form a rigid, insoluble matrix upon hydration, unlike non-hydraulic cement that remains porous and dissolves in water.

Typical Applications in Construction

Hydraulic cement is commonly used in applications requiring rapid setting and high durability under water exposure, such as underwater foundations, bridges, and dams. Non-hydraulic cement is typically employed in dry conditions where moisture protection is ensured, making it suitable for plastering, masonry, and indoor repairs. Understanding these distinctions ensures the selection of appropriate cement for specific construction needs, enhancing structural integrity and longevity.

Performance in Varied Environmental Conditions

Hydraulic cement sets and hardens through a chemical reaction with water, enabling it to perform reliably in wet and underwater environments, making it ideal for structures exposed to moisture or submerged conditions. Non-hydraulic cement requires air to set and is unsuitable for damp or underwater applications, as it loses strength and durability when exposed to moisture. Hydraulic cement's resistance to varying temperatures, freeze-thaw cycles, and chemical exposure ensures long-term stability in diverse environmental conditions.

Strength Development Over Time

Hydraulic cement gains strength through a chemical reaction with water, allowing it to harden underwater and develop high early and long-term strength, making it ideal for structural applications. Non-hydraulic cement, such as lime, requires exposure to air (carbonation) to harden and typically develops strength more slowly, resulting in lower early strength but improved workability. Over time, hydraulic cement achieves a more consistent and higher ultimate strength, crucial for durability and load-bearing requirements.

Main Advantages and Disadvantages

Hydraulic cement sets and hardens through a chemical reaction with water, allowing it to cure underwater and providing high durability and resistance to weathering, making it ideal for structural applications in wet environments. Non-hydraulic cement hardens by drying and requires air to set, which limits its use to dry conditions and results in lower water resistance and mechanical strength. The main disadvantage of hydraulic cement is its higher cost and potential for slower setting times, while non-hydraulic cement is less expensive but more prone to degradation when exposed to moisture.

Cost Comparison and Availability

Hydraulic cement, including Portland cement, generally has higher initial costs than non-hydraulic types like lime cement due to its complex manufacturing process and greater material durability. Availability of hydraulic cement is widespread globally, supported by extensive industrial production and distribution networks, making it more accessible for large-scale construction projects. Non-hydraulic cement, while often more affordable and produced locally in smaller quantities, has limited use in damp environments and may require more frequent maintenance, influencing overall lifecycle costs.

Ideal Use Cases in Concrete Structures

Hydraulic cement, such as Portland cement, sets and hardens through a chemical reaction with water, making it ideal for concrete structures exposed to wet conditions or underwater applications like dams and bridges. Non-hydraulic cement, including lime-based cements, requires air to cure and is best used in masonry works or restoration projects where moisture exposure is minimal. Selecting the proper cement type enhances durability and structural integrity by aligning material properties with environmental demands.

Hydraulic Cement vs Non-Hydraulic Cement Infographic

materialdif.com

materialdif.com