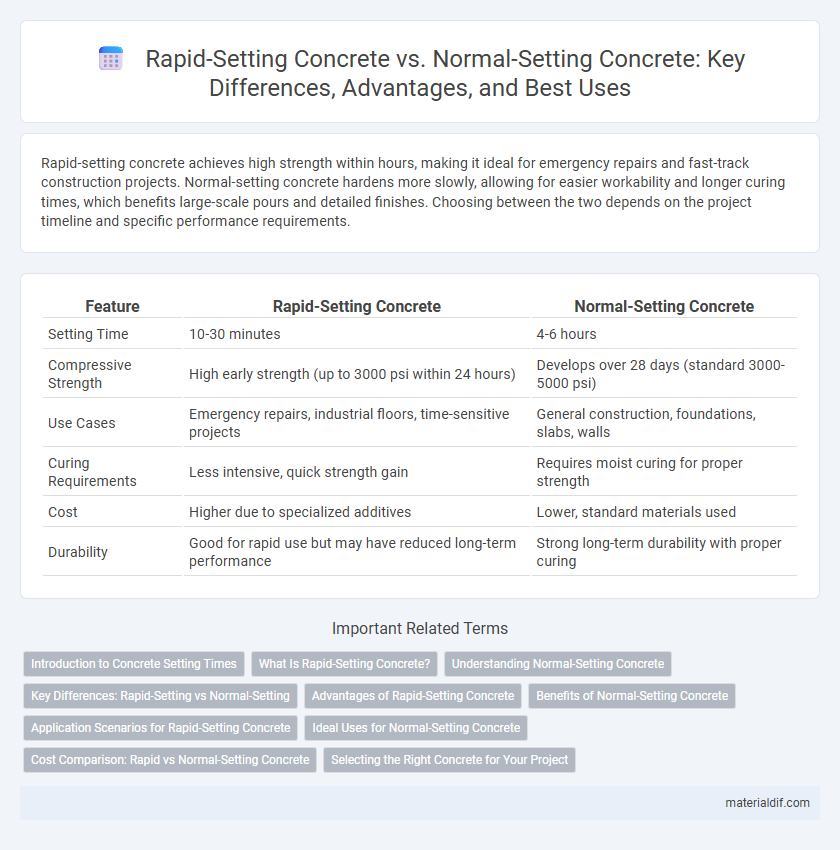

Rapid-setting concrete achieves high strength within hours, making it ideal for emergency repairs and fast-track construction projects. Normal-setting concrete hardens more slowly, allowing for easier workability and longer curing times, which benefits large-scale pours and detailed finishes. Choosing between the two depends on the project timeline and specific performance requirements.

Table of Comparison

| Feature | Rapid-Setting Concrete | Normal-Setting Concrete |

|---|---|---|

| Setting Time | 10-30 minutes | 4-6 hours |

| Compressive Strength | High early strength (up to 3000 psi within 24 hours) | Develops over 28 days (standard 3000-5000 psi) |

| Use Cases | Emergency repairs, industrial floors, time-sensitive projects | General construction, foundations, slabs, walls |

| Curing Requirements | Less intensive, quick strength gain | Requires moist curing for proper strength |

| Cost | Higher due to specialized additives | Lower, standard materials used |

| Durability | Good for rapid use but may have reduced long-term performance | Strong long-term durability with proper curing |

Introduction to Concrete Setting Times

Rapid-setting concrete achieves initial set within 20 to 40 minutes, significantly faster than normal-setting concrete, which sets in about 2 to 4 hours. This accelerated curing process allows for quicker project turnaround and early load application, making it ideal for time-sensitive repairs and cold-weather conditions. Understanding the chemical composition and admixtures influencing setting times is essential for selecting the appropriate concrete type for specific construction needs.

What Is Rapid-Setting Concrete?

Rapid-setting concrete is a specialized type of concrete characterized by its accelerated curing time, reaching initial set within minutes to hours compared to standard concrete, which typically takes 24 to 48 hours. It contains chemical admixtures like calcium chloride or aluminate cement that promote faster hydration, making it ideal for emergency repairs, cold weather applications, and projects requiring quick turnaround. This concrete achieves high early strength, enabling rapid load application and reducing downtime in construction activities.

Understanding Normal-Setting Concrete

Normal-setting concrete typically hardens within 6 to 12 hours, offering a balance between workability and strength development. It is composed of Portland cement, aggregates, water, and admixtures, designed to provide durability and consistent curing suitable for most construction projects. This type of concrete ensures proper hydration and microstructure formation, resulting in reliable compressive strength and long-term performance.

Key Differences: Rapid-Setting vs Normal-Setting

Rapid-setting concrete achieves initial set within 20 to 40 minutes, making it ideal for urgent repairs and cold weather applications, while normal-setting concrete typically sets in 4 to 6 hours, suitable for standard construction timelines. The chemical composition of rapid-setting concrete includes higher amounts of calcium aluminate, accelerating hydration compared to the Portland cement used in normal-setting concrete. Strength development in rapid-setting concrete reaches around 2000 psi within 3 hours, whereas normal-setting concrete attains this strength level only after 24 hours or more.

Advantages of Rapid-Setting Concrete

Rapid-setting concrete offers superior early strength development, allowing structures to bear loads within hours instead of days, significantly accelerating construction schedules. Its fast curing time minimizes downtime in infrastructure projects like road repairs and emergency fixes, reducing costs and traffic disruptions. Enhanced durability in harsh conditions and improved resistance to freeze-thaw cycles further extend the lifespan of repairs using rapid-setting concrete.

Benefits of Normal-Setting Concrete

Normal-setting concrete offers enhanced workability and extended curing time, allowing for precise molding and finishing in complex construction projects. Its slower hydration process improves long-term strength and durability, making it ideal for structural elements requiring high load-bearing capacity. This type of concrete also reduces thermal cracking risk by dissipating heat gradually during curing, which is beneficial for large-scale pours and critical infrastructure.

Application Scenarios for Rapid-Setting Concrete

Rapid-setting concrete is ideal for emergency repairs, road maintenance, and cold-weather construction due to its fast curing time, typically achieving initial set within 30 minutes to 2 hours. This concrete type is highly suitable for applications requiring quick load-bearing capacity, such as airport runways, bridge decks, and industrial floors where minimizing downtime is critical. Its use in precast concrete element fabrication allows faster demolding and production cycles, enabling accelerated project timelines.

Ideal Uses for Normal-Setting Concrete

Normal-setting concrete is ideal for large-scale construction projects where extended working time is essential, such as foundations, slabs, and structural beams. Its slower curing process allows for better handling, finishing, and adjustment, ensuring optimal strength development over time. This type of concrete is preferred in environments requiring precise placement and minimal risk of cold joints.

Cost Comparison: Rapid vs Normal-Setting Concrete

Rapid-setting concrete generally incurs higher material costs due to its specialized chemical admixtures that accelerate curing times compared to normal-setting concrete. Normal-setting concrete remains more cost-effective for large-scale projects thanks to its lower raw material expenses and less stringent handling requirements. However, the reduced labor and downtime expenses associated with rapid-setting concrete often offset the initial price difference in time-sensitive applications.

Selecting the Right Concrete for Your Project

Rapid-setting concrete achieves initial set within minutes, ideal for urgent repairs and accelerating construction timelines, while normal-setting concrete typically sets within hours, providing more workability for complex forms. Selecting the right concrete depends on project demands such as time constraints, structural requirements, and environmental conditions. Rapid-setting mixtures often contain additives like calcium chloride to enhance early strength, whereas normal-setting concrete relies on traditional hydration processes for long-term durability.

Rapid-setting concrete vs normal-setting concrete Infographic

materialdif.com

materialdif.com