Shotcrete and gunite are two methods of applying concrete, differing mainly in their mixing process; shotcrete uses a wet mix pumped through a hose, which allows for higher-quality control and less rebound. Gunite involves a dry mix propelled by compressed air, making it suitable for smaller projects where rapid setting is beneficial. Both techniques provide strong adhesion to complex surfaces, but shotcrete is preferred for larger structural applications due to its consistency and reduced dust generation.

Table of Comparison

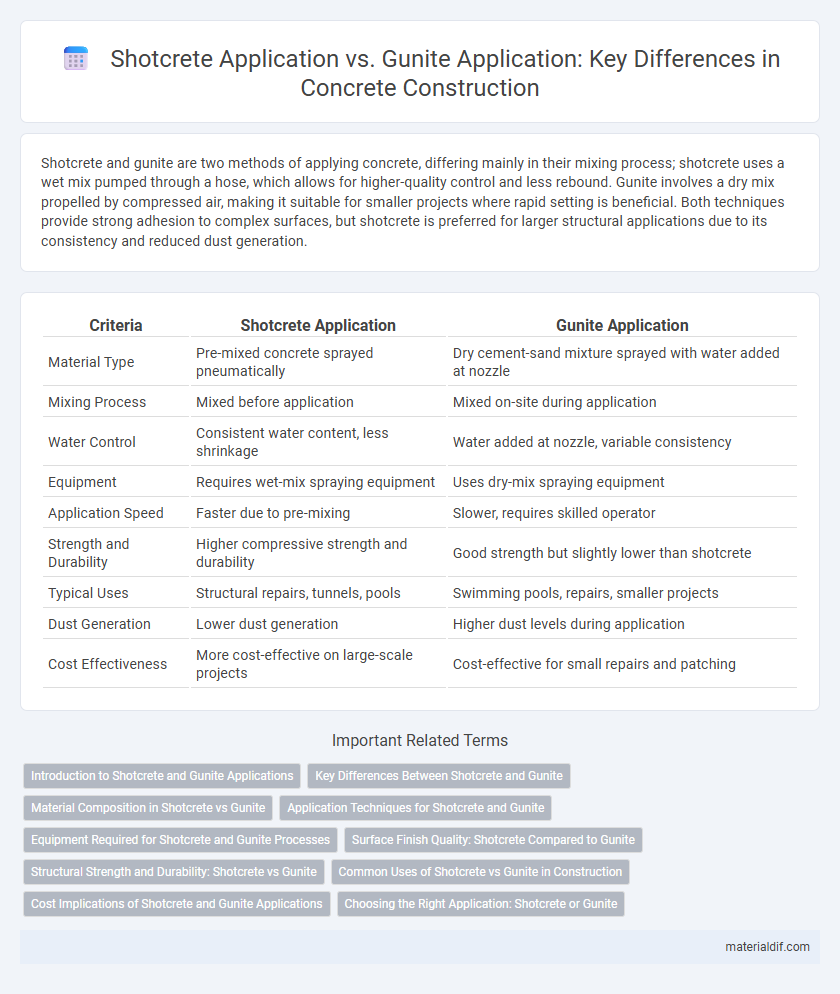

| Criteria | Shotcrete Application | Gunite Application |

|---|---|---|

| Material Type | Pre-mixed concrete sprayed pneumatically | Dry cement-sand mixture sprayed with water added at nozzle |

| Mixing Process | Mixed before application | Mixed on-site during application |

| Water Control | Consistent water content, less shrinkage | Water added at nozzle, variable consistency |

| Equipment | Requires wet-mix spraying equipment | Uses dry-mix spraying equipment |

| Application Speed | Faster due to pre-mixing | Slower, requires skilled operator |

| Strength and Durability | Higher compressive strength and durability | Good strength but slightly lower than shotcrete |

| Typical Uses | Structural repairs, tunnels, pools | Swimming pools, repairs, smaller projects |

| Dust Generation | Lower dust generation | Higher dust levels during application |

| Cost Effectiveness | More cost-effective on large-scale projects | Cost-effective for small repairs and patching |

Introduction to Shotcrete and Gunite Applications

Shotcrete and Gunite are both methods of applying concrete using a high-pressure hose but differ in their mixing processes; Shotcrete involves premixed concrete sprayed wet, while Gunite uses a dry mix that is hydrated at the nozzle. Shotcrete is preferred for structural repairs, swimming pools, and tunneling due to its consistent quality and higher rebound control. Gunite remains common in smaller-scale projects and repairs where dry-material storage and ease of transport are prioritized.

Key Differences Between Shotcrete and Gunite

Shotcrete and gunite are both methods of spraying concrete, but shotcrete uses a wet mix pumped through a hose, while gunite involves dry mix propelled by compressed air and water added at the nozzle. Shotcrete offers better control over moisture content and is preferred for large structural applications such as swimming pools and tunnel linings. Gunite is often favored for smaller repairs and patching due to its simplicity and lower water content, resulting in faster setting times and higher compressive strength.

Material Composition in Shotcrete vs Gunite

Shotcrete consists of a premixed dry or wet concrete blend that typically includes cement, sand, aggregates, and water, applied pneumatically at high velocity. Gunite, a dry-mix form of shotcrete, combines dry cement and aggregates that are pneumatically projected while water is added at the nozzle for mixing during application. The material composition differences impact workability, curing times, and equipment requirements for each method.

Application Techniques for Shotcrete and Gunite

Shotcrete application involves pneumatically projecting pre-mixed concrete through a hose at high velocity, allowing for faster placement and higher density with minimal rebound. Gunite application, on the other hand, requires dry cement and aggregate to be mixed at the nozzle, with water added during spraying, providing precise control over water-cement ratio and adaptability for repairs or complex shapes. Both techniques enable efficient concrete placement in vertical or overhead surfaces, but shotcrete is favored for large-scale projects due to its consistent mix quality and higher strength.

Equipment Required for Shotcrete and Gunite Processes

Shotcrete application requires specialized equipment such as high-pressure pumps, hoses, and spray nozzles designed for conveying and spraying a concrete mixture pneumatically. Gunite, a dry-mix shotcrete process, uses similar spraying apparatus but incorporates a water injection system at the nozzle to hydrate the dry materials upon application, demanding precise calibration of equipment for consistent mixture delivery. Both methods rely on air compressors and skilled operators to ensure efficient placement, with shotcrete equipment tailored for wet-mix handling and gunite apparatus optimized for the dry-mix process.

Surface Finish Quality: Shotcrete Compared to Gunite

Shotcrete delivers a smoother and more uniform surface finish compared to gunite due to its higher water-cement ratio and pneumatic application method, which reduces rebound and segregation. The precise control over mix consistency in shotcrete results in fewer voids and better compaction, enhancing the durability and aesthetic appeal of concrete structures. In contrast, gunite often requires additional finishing work to achieve comparable surface quality.

Structural Strength and Durability: Shotcrete vs Gunite

Shotcrete and gunite are both pneumatically applied concrete methods, but shotcrete typically uses a wetter mix that results in higher compressive strength and enhanced structural durability due to better compaction and reduced rebound. Gunite, being a dry-mix process, can be more prone to voids and inconsistent material density, potentially compromising long-term durability in structural applications. Comparative studies confirm that shotcrete's superior bond strength and lower permeability contribute to improved resistance against environmental stressors and structural fatigue.

Common Uses of Shotcrete vs Gunite in Construction

Shotcrete is commonly used for structural applications such as retaining walls, swimming pools, and tunnel linings due to its high compressive strength and excellent adhesion properties. Gunite is preferred in complex, custom-shaped projects like intricate swimming pool designs and slope stabilization because of its dry-mix delivery method allowing precise control over mix consistency. Both shotcrete and gunite enhance durability and reduce construction time but are selected based on project-specific requirements and environmental conditions.

Cost Implications of Shotcrete and Gunite Applications

Shotcrete and gunite applications differ significantly in cost implications due to their equipment and labor requirements. Shotcrete utilizes a wet-mix process, generally leading to higher material costs but faster application rates and reduced labor expenses. Gunite's dry-mix method often results in lower material costs but increased labor intensity and longer application times, impacting overall project budgets.

Choosing the Right Application: Shotcrete or Gunite

Choosing between shotcrete and gunite depends on project requirements such as strength, application method, and environmental conditions. Shotcrete, a wet-mix process with higher slump concrete, offers superior compaction and is ideal for structural work with complex shapes. Gunite, a dry-mix process, provides better control over moisture content and minimizes rebound, making it suitable for repairs and small-scale applications.

Shotcrete Application vs Gunite Application Infographic

materialdif.com

materialdif.com