High-strength concrete offers significantly greater load-bearing capacity and durability compared to conventional concrete, making it ideal for high-rise buildings and infrastructure requiring enhanced performance. Its lower water-cement ratio and advanced admixtures improve compressive strength and resistance to environmental factors, ensuring longer service life. Conventional concrete remains cost-effective for standard construction projects where extreme strength is not a critical requirement.

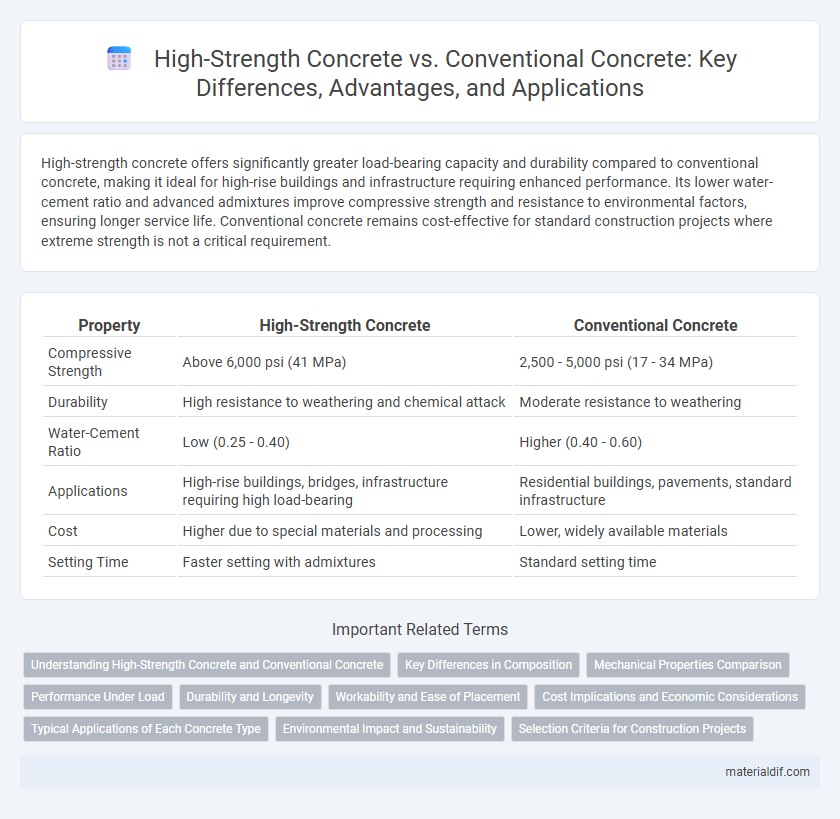

Table of Comparison

| Property | High-Strength Concrete | Conventional Concrete |

|---|---|---|

| Compressive Strength | Above 6,000 psi (41 MPa) | 2,500 - 5,000 psi (17 - 34 MPa) |

| Durability | High resistance to weathering and chemical attack | Moderate resistance to weathering |

| Water-Cement Ratio | Low (0.25 - 0.40) | Higher (0.40 - 0.60) |

| Applications | High-rise buildings, bridges, infrastructure requiring high load-bearing | Residential buildings, pavements, standard infrastructure |

| Cost | Higher due to special materials and processing | Lower, widely available materials |

| Setting Time | Faster setting with admixtures | Standard setting time |

Understanding High-Strength Concrete and Conventional Concrete

High-strength concrete typically achieves compressive strengths above 6,000 psi, utilizing low water-cement ratios and supplementary cementitious materials like silica fume or fly ash to enhance durability and reduce porosity. Conventional concrete generally ranges from 2,500 to 4,000 psi and uses a higher water-cement ratio, suitable for standard structural applications where extreme strength is not critical. The microstructure of high-strength concrete differs significantly from conventional concrete by having a denser cement matrix and improved aggregate bonding, resulting in superior mechanical properties and long-term performance.

Key Differences in Composition

High-strength concrete contains a higher cement content and lower water-to-cement ratio compared to conventional concrete, resulting in increased compressive strength typically exceeding 6,000 psi. It incorporates supplementary cementitious materials like silica fume or fly ash to enhance durability and reduce permeability. Conventional concrete generally uses a standard cement content with a water-to-cement ratio around 0.45 to 0.60, producing compressive strengths between 3,000 and 5,000 psi.

Mechanical Properties Comparison

High-strength concrete exhibits compressive strengths typically above 6,000 psi, significantly outperforming conventional concrete, which ranges between 3,000 to 4,000 psi. The increased mechanical properties include higher modulus of elasticity and improved tensile strength, enhancing structural durability and resistance to cracking. This makes high-strength concrete ideal for high-rise buildings and infrastructure demanding superior load-bearing capacity.

Performance Under Load

High-strength concrete exhibits significantly higher compressive strength, typically above 6,000 psi, compared to conventional concrete's 3,000 to 4,000 psi range, allowing it to support greater structural loads. Its enhanced performance under load results from a denser microstructure and lower porosity, improving durability and resistance to cracking. This makes high-strength concrete ideal for tall buildings, bridges, and heavy-duty infrastructure requiring superior load-bearing capacity and long-term reliability.

Durability and Longevity

High-strength concrete exhibits superior durability compared to conventional concrete due to its reduced permeability and enhanced resistance to chemical attacks and freeze-thaw cycles. The increased compressive strength, typically above 6000 psi, contributes to longer structural lifespan and reduced maintenance costs in infrastructure projects. Studies indicate that high-strength concrete can extend the service life of bridges and buildings by up to 50% under harsh environmental conditions.

Workability and Ease of Placement

High-strength concrete exhibits lower workability compared to conventional concrete due to its dense mix design and reduced water-cement ratio, which can challenge ease of placement. Specialized admixtures and superplasticizers are often necessary to enhance workability without compromising strength, enabling better flow and consolidation. Conventional concrete, with its higher water content, typically offers easier placement but lacks the mechanical performance and durability of high-strength variants.

Cost Implications and Economic Considerations

High-strength concrete incurs higher initial costs due to its specialized materials and manufacturing processes compared to conventional concrete. However, its enhanced durability and reduced maintenance needs can lead to lower lifecycle expenses and improved long-term economic value. When factoring in project longevity and performance, high-strength concrete often provides better cost-effectiveness despite the upfront investment.

Typical Applications of Each Concrete Type

High-strength concrete is commonly used in high-rise buildings, bridges, and infrastructure demanding superior load-bearing capacity and durability. Conventional concrete is typically applied in residential construction, pavements, and non-structural elements where standard strength and cost-effectiveness are priorities. The choice between high-strength and conventional concrete hinges on project specifications, structural requirements, and environmental conditions.

Environmental Impact and Sustainability

High-strength concrete significantly reduces material consumption by requiring less cement and aggregate for the same structural performance, lowering overall CO2 emissions during production. Its enhanced durability extends the lifespan of structures, minimizing the need for frequent repairs and demolition waste compared to conventional concrete. Incorporating supplementary cementitious materials like fly ash or slag further improves sustainability by reducing reliance on Portland cement, which is a major source of carbon emissions.

Selection Criteria for Construction Projects

High-strength concrete is selected over conventional concrete for construction projects demanding enhanced load-bearing capacity, durability, and resistance to harsh environmental conditions. Project criteria such as structural requirements, budget constraints, and project lifespan influence the choice, with high-strength concrete offering reduced member sizes and longer service life despite higher initial costs. Evaluating factors like compressive strength, workability, and curing time ensures optimal material performance aligned with project specifications.

High-Strength Concrete vs Conventional Concrete Infographic

materialdif.com

materialdif.com