Polymer-modified concrete incorporates polymers to enhance adhesion, flexibility, and chemical resistance, resulting in improved durability and reduced permeability compared to conventional concrete. This type of concrete is ideal for environments exposed to harsh weather conditions or chemical attacks, where traditional concrete may crack or deteriorate. While polymer-modified concrete tends to have a higher initial cost, its extended lifespan and enhanced performance often justify the investment in infrastructure projects.

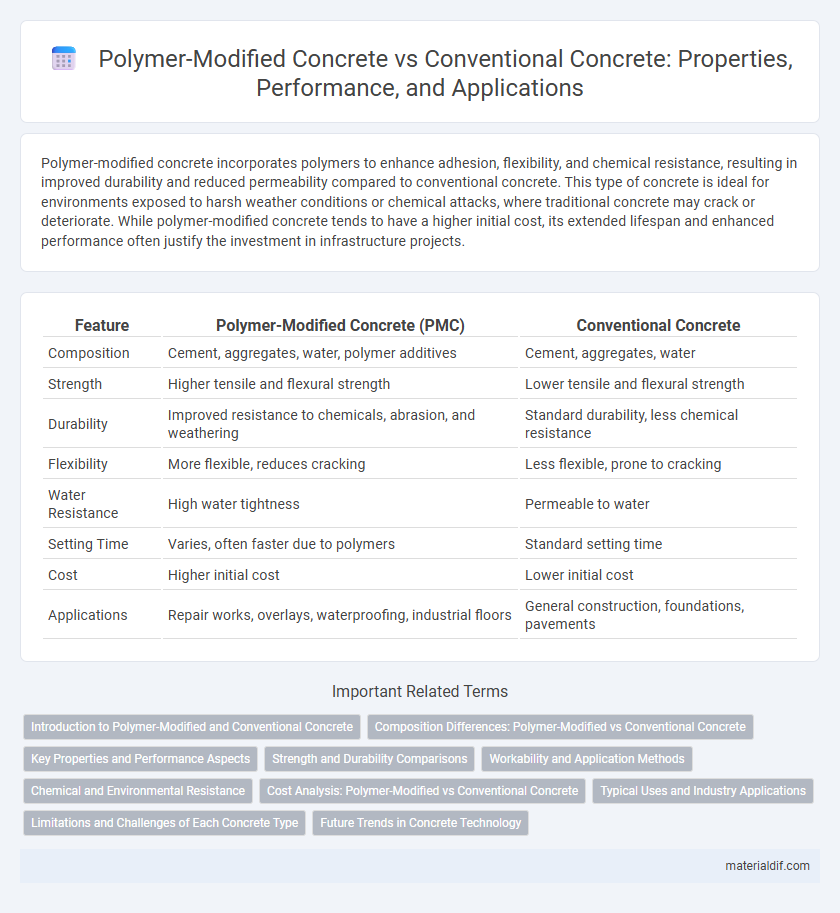

Table of Comparison

| Feature | Polymer-Modified Concrete (PMC) | Conventional Concrete |

|---|---|---|

| Composition | Cement, aggregates, water, polymer additives | Cement, aggregates, water |

| Strength | Higher tensile and flexural strength | Lower tensile and flexural strength |

| Durability | Improved resistance to chemicals, abrasion, and weathering | Standard durability, less chemical resistance |

| Flexibility | More flexible, reduces cracking | Less flexible, prone to cracking |

| Water Resistance | High water tightness | Permeable to water |

| Setting Time | Varies, often faster due to polymers | Standard setting time |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Repair works, overlays, waterproofing, industrial floors | General construction, foundations, pavements |

Introduction to Polymer-Modified and Conventional Concrete

Polymer-modified concrete (PMC) incorporates polymers such as latex, redispersible powders, or water-soluble polymers to enhance properties like adhesion, flexibility, and chemical resistance, making it suitable for repair and overlay applications. Conventional concrete primarily consists of cement, water, and aggregates, offering standard compressive strength but limited durability under aggressive environmental conditions. PMC provides improved crack resistance and reduced permeability compared to conventional concrete, resulting in extended service life in demanding construction environments.

Composition Differences: Polymer-Modified vs Conventional Concrete

Polymer-modified concrete incorporates polymers such as latex, acrylics, or styrene-butadiene rubber, which enhance bonding, flexibility, and resistance to chemicals and abrasion. Conventional concrete relies primarily on a mixture of cement, water, aggregates, and admixtures without polymer additives, making it more brittle and less durable under aggressive environmental conditions. The polymer content in polymer-modified concrete improves tensile strength and reduces permeability compared to conventional concrete, optimizing performance for specialized construction applications.

Key Properties and Performance Aspects

Polymer-modified concrete exhibits enhanced tensile strength, reduced permeability, and superior resistance to chemicals and abrasion compared to conventional concrete. Its improved adhesion and flexibility minimize cracking and increase durability under dynamic loads and harsh environmental conditions. These performance aspects make polymer-modified concrete ideal for infrastructure requiring extended service life and reduced maintenance costs.

Strength and Durability Comparisons

Polymer-modified concrete exhibits significantly higher compressive and tensile strength compared to conventional concrete, making it ideal for structures subjected to heavy loads and dynamic stresses. The incorporation of polymers enhances the durability of concrete by improving resistance to chemical attacks, abrasion, and freeze-thaw cycles, thereby extending the service life of infrastructure. Studies indicate polymer-modified concrete reduces permeability and microcracking, which are critical factors in preventing deterioration over time.

Workability and Application Methods

Polymer-modified concrete significantly enhances workability by improving flow characteristics and reducing segregation compared to conventional concrete, making it ideal for complex applications such as thin overlays and repair works. Its superior adhesion and flexibility allow for easier application through spraying, troweling, or casting, especially in environments requiring high durability and resistance to chemicals. Conventional concrete often requires more water or admixtures to achieve similar workability, limiting its use in specialized construction processes.

Chemical and Environmental Resistance

Polymer-modified concrete exhibits significantly enhanced chemical resistance due to the incorporation of polymer resins, which reduce permeability and improve bonding within the cement matrix, protecting the structure from aggressive chemicals like acids, sulfates, and chlorides. Conventional concrete, lacking these polymer additives, is more vulnerable to chemical attack and degradation, leading to a shorter lifespan in harsh environments. Environmentally, polymer-modified concrete offers better durability and reduced maintenance needs, while conventional concrete often requires more frequent repairs and replacement, contributing to higher environmental impact over time.

Cost Analysis: Polymer-Modified vs Conventional Concrete

Polymer-modified concrete (PMC) typically incurs higher initial costs due to the price of polymer additives, which range from 5% to 20% of the total material cost, compared to conventional concrete. However, PMC offers enhanced durability, chemical resistance, and reduced maintenance expenses, potentially lowering life-cycle costs by up to 30%. Conventional concrete has lower upfront costs but may require more frequent repairs and shorter service life, increasing long-term expenditure.

Typical Uses and Industry Applications

Polymer-modified concrete is extensively used in applications requiring enhanced durability, chemical resistance, and flexibility, such as industrial flooring, bridge decks, and repair works in wastewater treatment plants. Conventional concrete remains the standard choice for large-scale structures like residential buildings, highways, and foundations due to its cost-effectiveness and compressive strength. The construction and infrastructure industries leverage polymer-modified concrete for specialized performance needs, while conventional concrete dominates general construction projects.

Limitations and Challenges of Each Concrete Type

Polymer-modified concrete faces limitations such as higher material costs, extended curing times, and sensitivity to environmental conditions like temperature and humidity, which can affect the polymer's performance and bonding strength. Conventional concrete challenges include lower resistance to chemical attacks, reduced durability in harsh environments, and susceptibility to cracking under tensile stress without reinforcement. Both types require specific handling and curing procedures to optimize performance, with polymer-modified concrete demanding more precise quality control.

Future Trends in Concrete Technology

Polymer-modified concrete (PMC) integrates synthetic polymers that enhance durability, adhesion, and flexibility, positioning it as a forefront solution for future infrastructure demands. Emerging trends in concrete technology emphasize nanomaterials and smart polymers to improve self-healing properties and environmental resistance in PMC formulations. Conventional concrete continues to evolve with eco-friendly additives, but polymer-modified variants are projected to dominate high-performance and sustainable construction sectors due to superior mechanical and chemical performance.

Polymer-Modified Concrete vs Conventional Concrete Infographic

materialdif.com

materialdif.com