Roller-compacted concrete (RCC) offers a high-density, low-slump mix that is compacted by rollers, making it ideal for heavy-duty pavements and industrial floors due to its rapid installation and durable surface. Slipform concrete involves continuously pouring and shaping concrete using a moving form, which enables smooth, uniform surfaces and is commonly used for curbs, gutters, and sidewalks. Both methods provide efficient, robust solutions for concrete pet applications, but RCC is preferred for large-scale, load-bearing projects, while slipform excels in precise, linear structures.

Table of Comparison

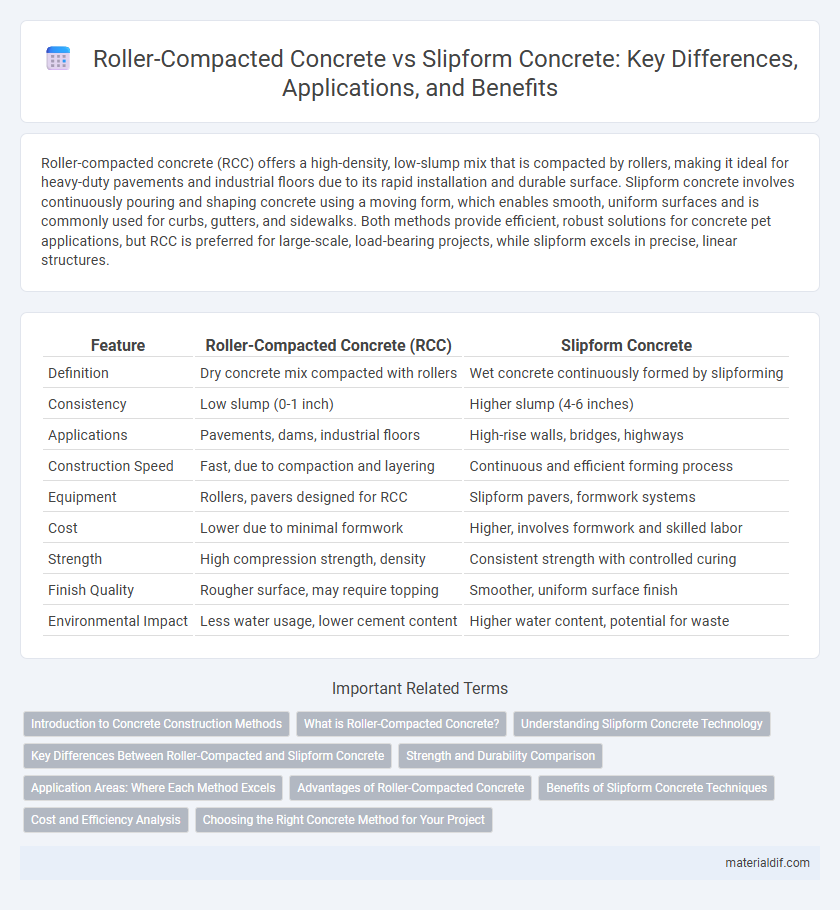

| Feature | Roller-Compacted Concrete (RCC) | Slipform Concrete |

|---|---|---|

| Definition | Dry concrete mix compacted with rollers | Wet concrete continuously formed by slipforming |

| Consistency | Low slump (0-1 inch) | Higher slump (4-6 inches) |

| Applications | Pavements, dams, industrial floors | High-rise walls, bridges, highways |

| Construction Speed | Fast, due to compaction and layering | Continuous and efficient forming process |

| Equipment | Rollers, pavers designed for RCC | Slipform pavers, formwork systems |

| Cost | Lower due to minimal formwork | Higher, involves formwork and skilled labor |

| Strength | High compression strength, density | Consistent strength with controlled curing |

| Finish Quality | Rougher surface, may require topping | Smoother, uniform surface finish |

| Environmental Impact | Less water usage, lower cement content | Higher water content, potential for waste |

Introduction to Concrete Construction Methods

Roller-compacted concrete (RCC) is a dry mix concrete method compacted by rollers, ideal for large-scale infrastructure such as dams and pavements, offering high durability and rapid construction time. Slipform concrete uses continuously moving forms to shape concrete structures like highways and curbs, enabling seamless, joint-free surfaces with consistent quality. Both methods optimize concrete placement efficiency but differ in material consistency, equipment, and application scope within civil engineering projects.

What is Roller-Compacted Concrete?

Roller-compacted concrete (RCC) is a dry, stiff mix used primarily for constructing pavements, dams, and industrial floors, characterized by its zero-slump consistency that enables high compaction with heavy rollers. RCC combines the strength and durability of conventional concrete with the rapid placement and lowered cost associated with asphalt paving techniques. The dense, low-void structure of RCC results in increased resistance to thermal cracking and reduced maintenance compared to traditional concrete methods.

Understanding Slipform Concrete Technology

Slipform concrete technology involves continuous pouring and simultaneous shaping using a moving form, allowing for seamless, durable structures like highways and tall walls. This method enhances efficiency and consistency in large-scale projects compared to roller-compacted concrete, which relies on compacting stiff concrete with rollers. Slipform technology's precision in shaping complex geometries provides superior surface finish and structural integrity for infrastructural applications.

Key Differences Between Roller-Compacted and Slipform Concrete

Roller-compacted concrete (RCC) is a dry mix compacted by heavy rollers, ideal for constructing thick pavements and dams with minimal formwork, while slipform concrete uses a wet mix continuously shaped by moving forms for seamless curbs, highways, and airport runways. RCC offers faster construction and higher durability with lower water content, whereas slipform concrete provides smoother finishes and greater precision for complex shapes. Key differences center on mix consistency, placement technique, and typical applications, influencing choice based on project requirements and desired surface characteristics.

Strength and Durability Comparison

Roller-compacted concrete (RCC) offers high compressive strength ideal for heavy-duty pavements due to its dense, low-slump mix, enhancing load-bearing capacity and reducing permeability. Slipform concrete, applied through continuous movement of formwork, delivers uniform density and improved surface finish, contributing to superior durability and resistance to environmental stressors. Both methods produce durable concrete structures, but RCC excels in rapid construction projects requiring robust strength, while slipform provides enhanced durability through precise consolidation and finishing.

Application Areas: Where Each Method Excels

Roller-compacted concrete (RCC) excels in large-scale infrastructure projects such as dam bases, heavy-duty pavements, and industrial flooring due to its high density, rapid placement, and cost-effectiveness. Slipform concrete is preferred for vertical structures like curbs, gutters, and highway barriers, providing smooth, continuous surfaces with precise control over shape and finish. Both methods optimize construction efficiency but differ significantly based on the structural orientation and project scale.

Advantages of Roller-Compacted Concrete

Roller-compacted concrete (RCC) offers significant advantages over slipform concrete, including faster placement and curing times due to its dry consistency and compatibility with heavy machinery. RCC provides superior durability and resistance to heavy loads, making it ideal for large-scale infrastructure projects like dams, pavements, and industrial floors. Its cost-effectiveness comes from reduced formwork requirements and lower labor intensity compared to traditional slipform concrete methods.

Benefits of Slipform Concrete Techniques

Slipform concrete techniques enable continuous, uniform placement of concrete that enhances structural integrity and minimizes cold joints compared to roller-compacted concrete. This method improves surface finish quality and accelerates construction speed through automated form movement. Slipform concrete is ideal for vertical structures like silos and retaining walls, providing superior durability and reduced labor costs.

Cost and Efficiency Analysis

Roller-compacted concrete (RCC) offers significant cost savings due to its lower material and labor expenses compared to slipform concrete, making it ideal for large-scale pavement projects. RCC enables faster construction cycles with minimal formwork requirements, increasing overall efficiency on-site. Slipform concrete provides smoother finishes and is preferred for complex geometries but entails higher costs and longer curing times.

Choosing the Right Concrete Method for Your Project

Roller-compacted concrete (RCC) offers high durability and rapid construction, making it ideal for large-scale industrial floors and heavy-duty pavements. Slipform concrete provides superior surface smoothness and is preferred for curbs, highways, and airport runways where precise finish and alignment are critical. Selecting the appropriate concrete method depends on project requirements such as load-bearing capacity, speed of completion, and surface finish quality.

Roller-compacted Concrete vs Slipform Concrete Infographic

materialdif.com

materialdif.com