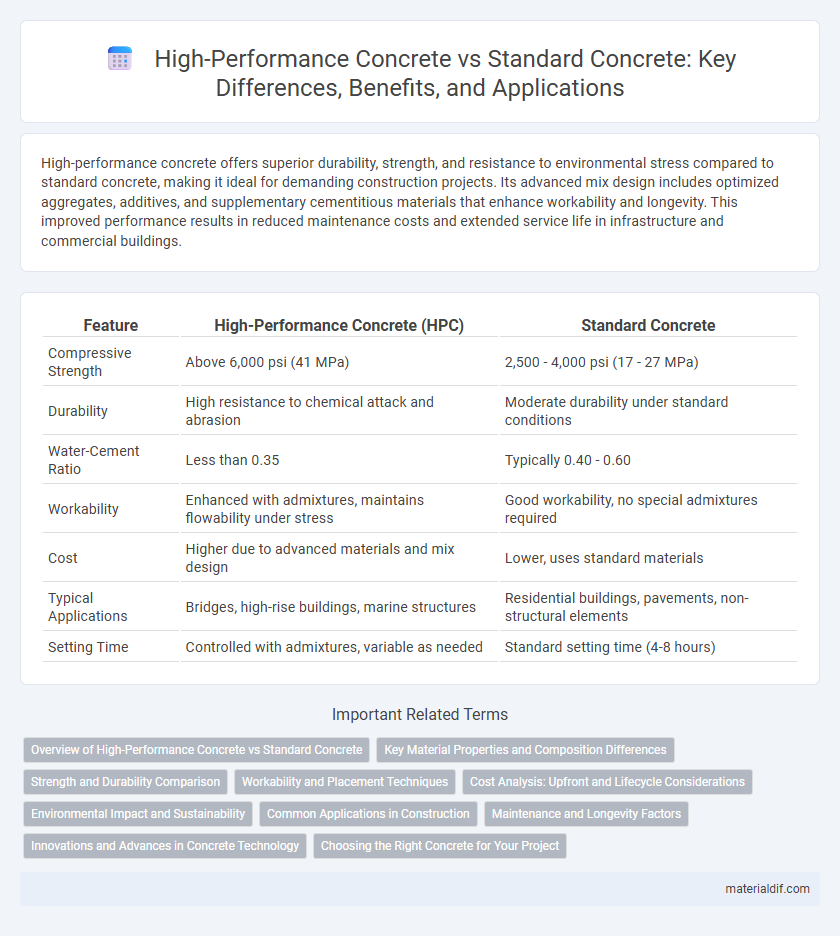

High-performance concrete offers superior durability, strength, and resistance to environmental stress compared to standard concrete, making it ideal for demanding construction projects. Its advanced mix design includes optimized aggregates, additives, and supplementary cementitious materials that enhance workability and longevity. This improved performance results in reduced maintenance costs and extended service life in infrastructure and commercial buildings.

Table of Comparison

| Feature | High-Performance Concrete (HPC) | Standard Concrete |

|---|---|---|

| Compressive Strength | Above 6,000 psi (41 MPa) | 2,500 - 4,000 psi (17 - 27 MPa) |

| Durability | High resistance to chemical attack and abrasion | Moderate durability under standard conditions |

| Water-Cement Ratio | Less than 0.35 | Typically 0.40 - 0.60 |

| Workability | Enhanced with admixtures, maintains flowability under stress | Good workability, no special admixtures required |

| Cost | Higher due to advanced materials and mix design | Lower, uses standard materials |

| Typical Applications | Bridges, high-rise buildings, marine structures | Residential buildings, pavements, non-structural elements |

| Setting Time | Controlled with admixtures, variable as needed | Standard setting time (4-8 hours) |

Overview of High-Performance Concrete vs Standard Concrete

High-performance concrete (HPC) offers significantly enhanced strength, durability, and resistance to environmental factors compared to standard concrete, enabling longer service life and reduced maintenance costs. HPC incorporates advanced admixtures, supplementary cementitious materials, and optimized mix designs to achieve superior mechanical properties and improved workability. Standard concrete typically contains ordinary Portland cement and aggregates with minimal additives, making it more basic in performance but cost-effective for general construction purposes.

Key Material Properties and Composition Differences

High-performance concrete (HPC) exhibits superior durability, higher compressive strength exceeding 70 MPa, and enhanced resistance to chemical attacks compared to standard concrete, which typically ranges from 20 to 40 MPa. HPC incorporates optimized mix designs with low water-cement ratios, supplementary cementitious materials like fly ash or silica fume, and advanced admixtures to improve workability and reduce permeability. Standard concrete generally uses a higher water-cement ratio and less supplementary materials, resulting in lower density and less resistance to environmental stressors.

Strength and Durability Comparison

High-performance concrete (HPC) exhibits compressive strengths exceeding 70 MPa, significantly outperforming standard concrete which typically ranges from 20 to 40 MPa. HPC's enhanced durability results from refined mix designs incorporating supplementary cementitious materials like silica fume and fly ash, which improve resistance to chemical attack, freeze-thaw cycles, and abrasion. This superior strength and durability make HPC ideal for infrastructure exposed to harsh environmental conditions and high structural loads.

Workability and Placement Techniques

High-performance concrete (HPC) offers superior workability compared to standard concrete due to its optimized mix design, including lower water-to-cement ratios and carefully selected admixtures such as superplasticizers. This enhanced workability facilitates complex placement techniques like pumping and slip forming, ensuring dense compaction and minimal segregation in structural elements. Conversely, standard concrete's higher water content results in lower strength and challenges in achieving uniform placement, often requiring more manual labor and vibration to prevent honeycombing.

Cost Analysis: Upfront and Lifecycle Considerations

High-performance concrete (HPC) typically incurs higher upfront costs due to advanced materials and specialized mixing techniques, but its enhanced durability and reduced maintenance needs lower lifecycle expenses significantly compared to standard concrete. Lifecycle cost analysis shows HPC's resistance to environmental degradation and improved strength extends the service life of structures, resulting in fewer repairs and replacements over time. Evaluating total cost of ownership reveals that while initial investments in HPC are greater, long-term savings justify its use in infrastructure projects requiring longevity and reduced maintenance budgets.

Environmental Impact and Sustainability

High-performance concrete (HPC) significantly reduces environmental impact compared to standard concrete by incorporating supplementary cementitious materials like fly ash and slag, which lower cement content and CO2 emissions. HPC's enhanced durability and strength extend the lifespan of structures, minimizing repair needs and resource consumption over time. Its optimized mix design reduces permeability, preventing degradation and promoting sustainable construction practices through lifecycle efficiency.

Common Applications in Construction

High-performance concrete (HPC) is predominantly utilized in infrastructure projects requiring enhanced strength and durability, such as bridges, high-rise buildings, and marine structures. Standard concrete is commonly applied in residential foundations, sidewalks, and pavements where moderate strength and standard durability suffice. Construction sectors favor HPC for critical load-bearing elements and aggressive environmental conditions, while standard concrete suits general-purpose, non-structural applications.

Maintenance and Longevity Factors

High-performance concrete (HPC) exhibits superior durability and reduced permeability compared to standard concrete, significantly lowering maintenance requirements over its lifespan. Its enhanced resistance to chemical attacks, freeze-thaw cycles, and abrasion extends service life by up to 50% in aggressive environments. Standard concrete, while cost-effective initially, often demands more frequent repairs due to higher susceptibility to cracking and deterioration under stress.

Innovations and Advances in Concrete Technology

High-performance concrete (HPC) incorporates advanced materials like silica fume, fly ash, and superplasticizers to achieve superior strength, durability, and workability compared to standard concrete. Innovations such as nanotechnology and fiber reinforcement enhance HPC's fracture resistance and reduce permeability, extending the lifespan of infrastructure. These technological advances enable faster curing and improved sustainability by optimizing the mix design for specific environmental conditions.

Choosing the Right Concrete for Your Project

High-performance concrete (HPC) offers superior durability, strength, and resistance to environmental stressors compared to standard concrete, making it ideal for infrastructure projects demanding longevity and load-bearing capacity. Standard concrete is suitable for residential and non-critical structures where cost-efficiency and ease of use are priorities. Selecting the right concrete involves evaluating project requirements such as exposure conditions, structural demands, and budget constraints to ensure optimal performance and lifespan.

High-Performance Concrete vs Standard Concrete Infographic

materialdif.com

materialdif.com