Lean concrete contains a lower cement content and higher aggregate proportion, making it more economical and suitable for foundational or non-structural applications. Rich concrete features a higher cement-to-aggregate ratio, resulting in increased strength and durability ideal for structural components exposed to heavy loads or harsh conditions. Choosing between lean and rich concrete depends on the required strength, durability, and budget considerations for the construction project.

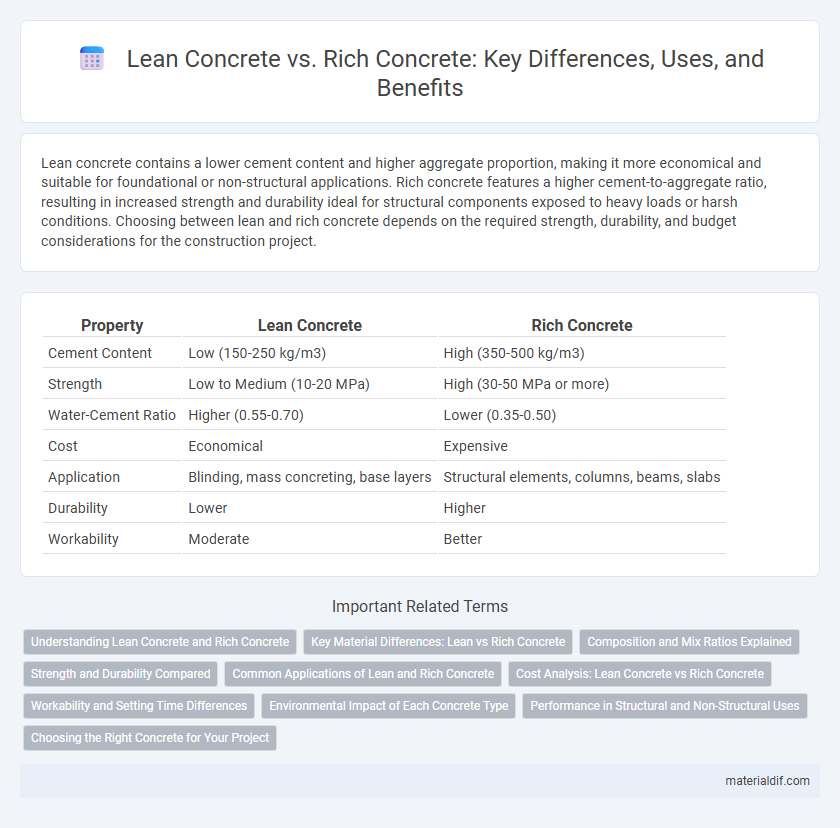

Table of Comparison

| Property | Lean Concrete | Rich Concrete |

|---|---|---|

| Cement Content | Low (150-250 kg/m3) | High (350-500 kg/m3) |

| Strength | Low to Medium (10-20 MPa) | High (30-50 MPa or more) |

| Water-Cement Ratio | Higher (0.55-0.70) | Lower (0.35-0.50) |

| Cost | Economical | Expensive |

| Application | Blinding, mass concreting, base layers | Structural elements, columns, beams, slabs |

| Durability | Lower | Higher |

| Workability | Moderate | Better |

Understanding Lean Concrete and Rich Concrete

Lean concrete contains a lower cement-to-aggregate ratio, resulting in reduced strength and higher porosity, which makes it ideal for base or sub-base layers in construction. Rich concrete features a higher cement content, providing enhanced durability, strength, and resistance to environmental factors, commonly used in structural elements like beams and slabs. Understanding the mix proportions and application requirements is crucial for selecting the appropriate concrete type to ensure structural integrity and cost-effectiveness.

Key Material Differences: Lean vs Rich Concrete

Lean concrete contains a lower cement content, typically ranging from 150 to 250 kg per cubic meter, resulting in reduced strength and durability compared to rich concrete. Rich concrete features a higher cement content, usually between 300 to 450 kg per cubic meter, enhancing its compressive strength and resistance to environmental factors. The water-cement ratio in lean concrete is higher, leading to increased porosity, whereas rich concrete has a lower water-cement ratio, contributing to its dense and robust structure.

Composition and Mix Ratios Explained

Lean concrete contains a lower cement content and higher aggregate ratio, often with a water-cement ratio above 0.50, making it suitable for non-structural applications where strength is not critical. Rich concrete features a higher cement content with a lower water-cement ratio, typically below 0.40, enhancing durability and compressive strength for structural uses. The mix ratio for lean concrete might be 1:3:6 (cement:sand:aggregate), whereas rich concrete commonly uses ratios like 1:1.5:3 or 1:2:4 to achieve greater density and bonding.

Strength and Durability Compared

Lean concrete contains a lower cement content and higher aggregate ratio, resulting in moderate strength and reduced durability compared to rich concrete. Rich concrete, with increased cement content, achieves higher compressive strength and enhanced resistance to environmental degradation. The selection depends on structural requirements where rich concrete is preferred for load-bearing elements requiring long-term durability.

Common Applications of Lean and Rich Concrete

Lean concrete is commonly used as a base or sub-base material in road construction, foundations, and mass concrete works due to its lower cement content and cost-effectiveness. Rich concrete, with higher cement content, is preferred in structural elements requiring high strength and durability, such as beams, columns, and prestressed concrete members. Both types serve distinct roles: lean concrete provides economical support layers, while rich concrete ensures robust structural integrity in critical applications.

Cost Analysis: Lean Concrete vs Rich Concrete

Lean concrete, characterized by low cement content and high aggregate ratio, offers significant cost savings due to reduced cement usage, making it ideal for non-structural applications and mass concrete works. Rich concrete contains higher cement content, increasing material costs but providing enhanced strength, durability, and workability, essential for structural elements exposed to high stress or aggressive environments. Cost analysis reveals lean concrete as the economical choice for large volumes with moderate performance needs, while rich concrete justifies higher expenses through superior performance, minimizing long-term maintenance and repair costs.

Workability and Setting Time Differences

Lean concrete contains lower cement content, resulting in reduced workability and faster setting times compared to rich concrete. Rich concrete, with higher cement content, offers superior workability due to increased paste volume and exhibits longer setting times that allow for better finishing and placing. The balance between cement proportions directly impacts the ease of mixing, placing, and the curing process in construction applications.

Environmental Impact of Each Concrete Type

Lean concrete, characterized by a lower cement content and higher aggregate ratio, significantly reduces carbon emissions due to decreased clinker usage, which is the primary source of CO2 in concrete production. In contrast, rich concrete with higher cement content has a substantially larger environmental footprint, contributing to increased greenhouse gas emissions and resource depletion. Utilizing lean concrete aligns with sustainable construction practices by minimizing embodied carbon and conserving raw materials without compromising structural integrity.

Performance in Structural and Non-Structural Uses

Lean concrete features a lower cement content and higher aggregate ratio, resulting in reduced strength but improved workability and cost-efficiency, suitable for non-structural uses like pavements and foundations. Rich concrete contains a higher cement proportion, offering enhanced compressive strength and durability, making it ideal for structural applications such as columns, beams, and load-bearing walls. The performance differences impact structural integrity where rich concrete ensures higher load capacity, while lean concrete is preferred for non-critical, economical construction tasks.

Choosing the Right Concrete for Your Project

Lean concrete contains a lower cement content and higher aggregate ratio, making it cost-effective and suitable for structural filling and foundations with less load-bearing demand. Rich concrete features a higher cement to aggregate ratio, providing enhanced strength, durability, and finish quality, ideal for structural elements requiring high performance. Selecting the right concrete depends on load requirements, environmental conditions, and project budget to ensure optimal durability and cost-efficiency.

Lean Concrete vs Rich Concrete Infographic

materialdif.com

materialdif.com