Silica fume significantly enhances concrete's strength and durability by filling microscopic voids and improving the bond between cement and aggregates, making it ideal for high-performance structures. Metakaolin, a pozzolanic material derived from kaolin clay, improves workability and reduces permeability, contributing to better resistance against chemical attacks and elevated durability. Both additives enhance concrete properties, but silica fume is preferred for ultra-high-strength applications, while metakaolin is favored for improving durability and mitigating alkali-silica reactions.

Table of Comparison

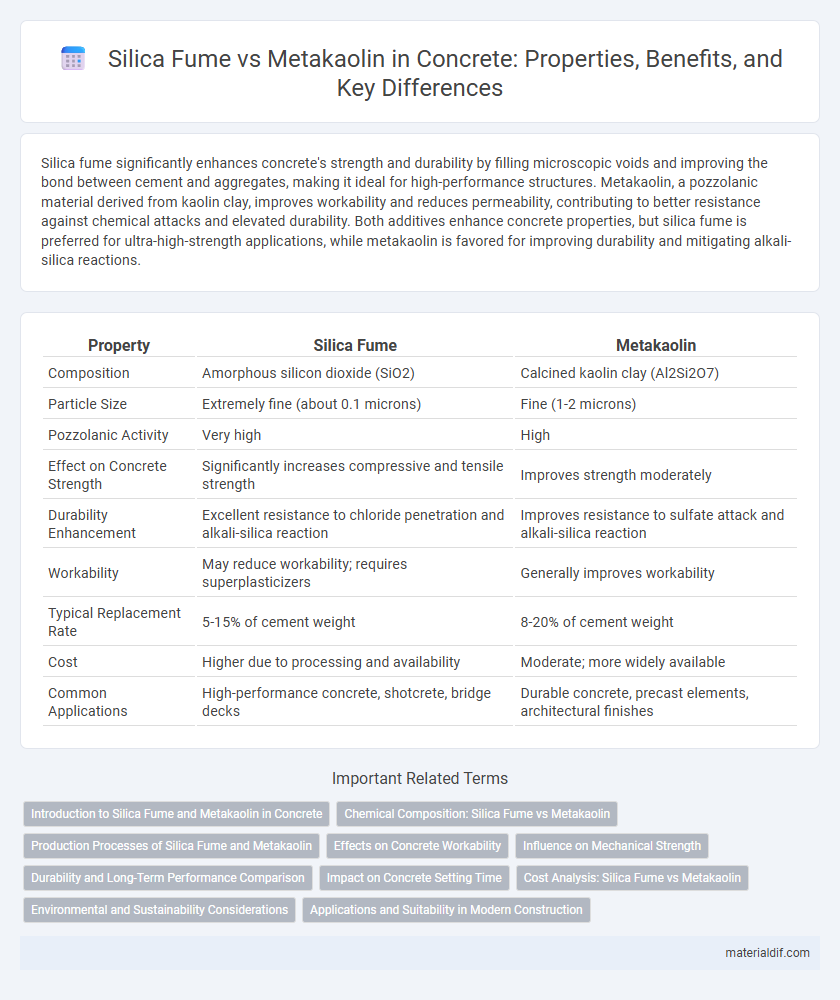

| Property | Silica Fume | Metakaolin |

|---|---|---|

| Composition | Amorphous silicon dioxide (SiO2) | Calcined kaolin clay (Al2Si2O7) |

| Particle Size | Extremely fine (about 0.1 microns) | Fine (1-2 microns) |

| Pozzolanic Activity | Very high | High |

| Effect on Concrete Strength | Significantly increases compressive and tensile strength | Improves strength moderately |

| Durability Enhancement | Excellent resistance to chloride penetration and alkali-silica reaction | Improves resistance to sulfate attack and alkali-silica reaction |

| Workability | May reduce workability; requires superplasticizers | Generally improves workability |

| Typical Replacement Rate | 5-15% of cement weight | 8-20% of cement weight |

| Cost | Higher due to processing and availability | Moderate; more widely available |

| Common Applications | High-performance concrete, shotcrete, bridge decks | Durable concrete, precast elements, architectural finishes |

Introduction to Silica Fume and Metakaolin in Concrete

Silica fume, a byproduct of silicon metal production, is an ultrafine pozzolanic material that significantly enhances concrete durability and strength by filling micropores and reacting with calcium hydroxide to form additional calcium silicate hydrate. Metakaolin, derived from calcined kaolinite clay, improves concrete's mechanical properties and resistance to chemical attack through its high pozzolanic reactivity and refinement of the cement matrix. Both materials serve as vital supplementary cementitious components, optimizing concrete performance in structural applications.

Chemical Composition: Silica Fume vs Metakaolin

Silica fume primarily consists of amorphous silicon dioxide (SiO2) with a high silica content exceeding 85%, enhancing pozzolanic reactivity and improving concrete durability. Metakaolin is composed of dehydroxylated kaolinite clay, rich in alumina (Al2O3) and silica (SiO2), typically containing about 40-55% alumina and 50-55% silica, contributing to improved concrete strength and reduced permeability. The differing chemical compositions influence their pozzolanic activity and suitability for specific concrete performance requirements.

Production Processes of Silica Fume and Metakaolin

Silica fume is produced through the high-temperature reduction of quartz in electric arc furnaces during silicon metal or ferrosilicon alloy manufacturing, resulting in ultrafine amorphous silica particles. Metakaolin is obtained by the controlled thermal activation of purified kaolin clay at temperatures between 650degC and 800degC, causing dehydroxylation and structural transformation into an amorphous, highly reactive pozzolan. The distinct production methods yield different particle morphology and reactivity levels, influencing their performance in concrete applications.

Effects on Concrete Workability

Silica fume significantly reduces concrete workability due to its ultrafine particles and high surface area, which increase water demand and cause a sticky mix consistency. Metakaolin, while also a pozzolanic material, has a less pronounced effect on workability, often improving it by refining the particle packing and reducing bleeding. Optimizing water-to-cement ratios and employing superplasticizers are essential when incorporating silica fume to maintain effective concrete workability.

Influence on Mechanical Strength

Silica fume significantly enhances concrete's mechanical strength by filling micro-pores and refining the microstructure, resulting in increased compressive and tensile strength. Metakaolin also improves mechanical properties by accelerating cement hydration and increasing the density of the cement matrix, though its strength gains are generally less pronounced than those achieved with silica fume. Comparative studies show that concrete with silica fume exhibits superior early and long-term strength development compared to metakaolin-modified mixes.

Durability and Long-Term Performance Comparison

Silica fume significantly enhances concrete durability by reducing permeability and increasing resistance to chloride ion penetration, which protects reinforcement from corrosion over time. Metakaolin improves long-term performance by refining the pore structure and boosting resistance to alkali-silica reaction and sulfate attack, thereby extending concrete lifespan. Comparative studies show silica fume excels in abrasion and chemical resistance, while metakaolin offers superior dimensional stability and resistance to carbonation.

Impact on Concrete Setting Time

Silica fume significantly accelerates concrete setting time due to its high reactivity and fine particle size, which enhances early hydration. Metakaolin, while also reactive, tends to moderately slow down the setting process because of its pozzolanic reaction that consumes calcium hydroxide over a longer period. Understanding these impacts on setting time is crucial for optimizing mix designs in applications requiring precise curing schedules.

Cost Analysis: Silica Fume vs Metakaolin

Silica fume typically incurs higher costs compared to metakaolin due to its complex production process involving the capture of silicon metal or ferrosilicon alloy fumes. Metakaolin, derived from calcined kaolin clay, offers a more economical alternative with relatively lower raw material and processing expenses. Cost efficiency in concrete applications depends on balancing the enhanced durability and strength benefits of silica fume against the budget-friendly and pozzolanic reactivity of metakaolin.

Environmental and Sustainability Considerations

Silica fume enhances concrete durability and reduces permeability, contributing to longer service life and lower maintenance, which supports sustainability through resource conservation. Metakaolin, derived from kaolin clay, is a natural pozzolanic material that reduces cement content and CO2 emissions during production, promoting a greener concrete mixture. Both materials improve environmental performance, but metakaolin offers advantages in renewable sourcing and lower embodied carbon compared to the byproduct-based silica fume.

Applications and Suitability in Modern Construction

Silica fume enhances concrete durability and strength in high-performance applications such as bridges, tunnels, and industrial floors due to its ultra-fine particles and pozzolanic properties. Metakaolin improves workability, reduces permeability, and mitigates alkali-silica reaction, making it ideal for architectural concrete and precast elements requiring superior surface finish and durability. Both materials are suitable for modern construction, with silica fume favored for extreme strength and metakaolin for enhanced aesthetics and chemical resistance.

Silica fume vs metakaolin Infographic

materialdif.com

materialdif.com