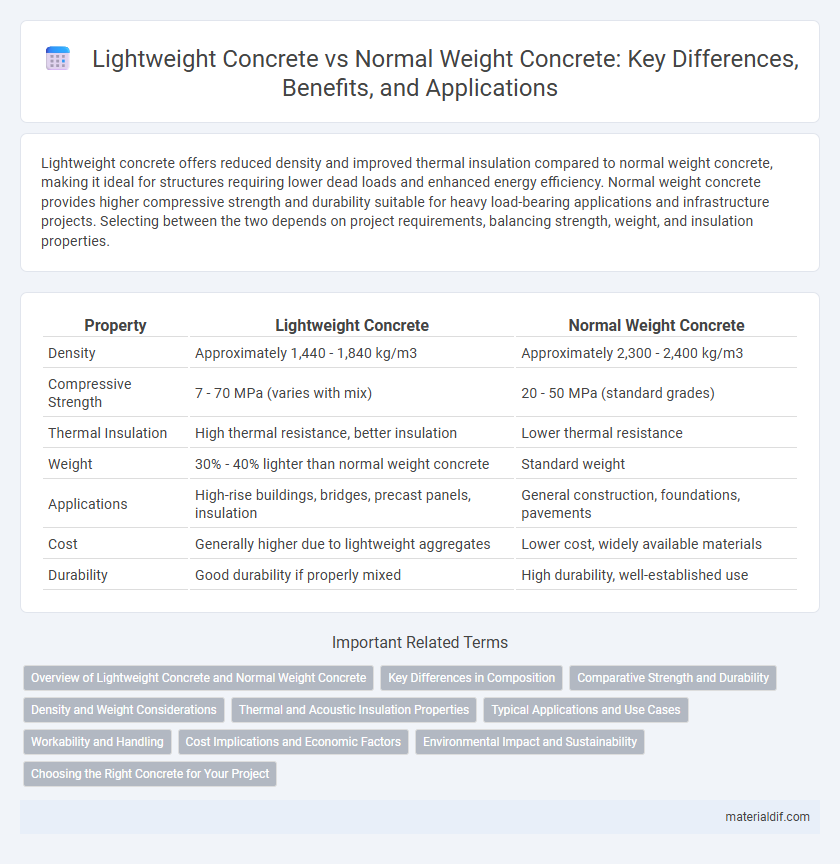

Lightweight concrete offers reduced density and improved thermal insulation compared to normal weight concrete, making it ideal for structures requiring lower dead loads and enhanced energy efficiency. Normal weight concrete provides higher compressive strength and durability suitable for heavy load-bearing applications and infrastructure projects. Selecting between the two depends on project requirements, balancing strength, weight, and insulation properties.

Table of Comparison

| Property | Lightweight Concrete | Normal Weight Concrete |

|---|---|---|

| Density | Approximately 1,440 - 1,840 kg/m3 | Approximately 2,300 - 2,400 kg/m3 |

| Compressive Strength | 7 - 70 MPa (varies with mix) | 20 - 50 MPa (standard grades) |

| Thermal Insulation | High thermal resistance, better insulation | Lower thermal resistance |

| Weight | 30% - 40% lighter than normal weight concrete | Standard weight |

| Applications | High-rise buildings, bridges, precast panels, insulation | General construction, foundations, pavements |

| Cost | Generally higher due to lightweight aggregates | Lower cost, widely available materials |

| Durability | Good durability if properly mixed | High durability, well-established use |

Overview of Lightweight Concrete and Normal Weight Concrete

Lightweight concrete is characterized by a reduced density, typically ranging from 1,440 to 1,840 kg/m3, achieved by using lightweight aggregates such as expanded clay, shale, or pumice, which enhance thermal insulation and reduce structural load. Normal weight concrete has a density of approximately 2,300 to 2,400 kg/m3, composed primarily of natural aggregates like crushed stone and gravel, offering higher compressive strength and durability for general construction purposes. Both types of concrete serve distinct applications based on their density, strength, and thermal properties, influencing design decisions in structural and non-structural projects.

Key Differences in Composition

Lightweight concrete is composed of lightweight aggregates such as expanded clay, shale, or pumice, reducing its density compared to normal weight concrete, which uses conventional aggregates like gravel and crushed stone. The reduced weight in lightweight concrete leads to lower thermal conductivity and improved insulation properties, whereas normal weight concrete provides higher compressive strength due to its denser aggregate composition. Water-cement ratios and admixture types may vary between the two to optimize workability and durability for specific structural requirements.

Comparative Strength and Durability

Lightweight concrete typically exhibits lower compressive strength compared to normal weight concrete, making it suitable for non-structural applications where reduced load is critical. Normal weight concrete offers superior durability, with higher resistance to abrasion, impact, and harsh environmental conditions due to its denser aggregate composition. The choice between these concretes depends on balancing strength requirements with the benefits of reduced dead load and improved thermal insulation provided by lightweight concrete.

Density and Weight Considerations

Lightweight concrete typically has a density ranging from 1,440 to 1,840 kg/m3, significantly lower than normal weight concrete which generally ranges from 2,200 to 2,500 kg/m3. This reduction in density results in lighter structural elements, improving ease of handling and reducing dead loads on foundations. Weight considerations are critical in applications like high-rise buildings and bridges where minimizing structural load can enhance design efficiency and reduce construction costs.

Thermal and Acoustic Insulation Properties

Lightweight concrete offers superior thermal insulation due to its low density and high air content, reducing heat transfer significantly compared to normal weight concrete. Acoustic insulation is also enhanced in lightweight concrete as its porous structure absorbs sound waves more effectively, minimizing noise transmission. Normal weight concrete, while stronger, provides less thermal and acoustic insulation, making lightweight concrete preferable for energy-efficient and sound-sensitive construction applications.

Typical Applications and Use Cases

Lightweight concrete is ideal for high-rise buildings, bridges, and precast panels where reduced dead load enhances structural efficiency and seismic resistance. Normal weight concrete is predominantly used in foundations, pavements, and heavy-duty industrial floors due to its superior compressive strength and durability. Both types offer distinct advantages tailored to specific construction needs, optimizing performance and cost-effectiveness.

Workability and Handling

Lightweight concrete offers improved workability due to its lower density and reduced aggregate weight, making it easier to mix, transport, and place compared to normal weight concrete. The reduced weight enhances handling on site, especially in elevated structures or complex formworks, minimizing labor effort and equipment strain. Normal weight concrete, while denser and stronger, requires more effort during handling, often leading to increased fatigue and slower placement rates.

Cost Implications and Economic Factors

Lightweight concrete typically incurs higher initial costs due to specialized materials like expanded clay or shale, affecting budget allocations in construction projects. Normal weight concrete offers cost efficiency through widespread availability of standard aggregates, reducing transportation and material expenses. Economic considerations must include lifecycle costs, where lightweight concrete's thermal insulation and reduced structural load can lead to long-term savings despite upfront premiums.

Environmental Impact and Sustainability

Lightweight concrete significantly reduces the environmental impact through lower raw material consumption and decreased transportation emissions due to its reduced density compared to normal weight concrete. Its enhanced thermal insulation properties contribute to energy savings in buildings, promoting sustainability by lowering heating and cooling demands over the structure's lifecycle. Normal weight concrete, while stronger, generally requires more energy-intensive aggregates and produces higher embodied carbon, making lightweight concrete a preferred choice for eco-friendly construction projects.

Choosing the Right Concrete for Your Project

Lightweight concrete offers superior thermal insulation and reduced structural load, making it ideal for high-rise buildings and projects requiring energy efficiency. Normal weight concrete provides higher compressive strength and durability, suited for heavy load-bearing structures like bridges and foundations. Selecting the right concrete depends on project-specific factors such as load requirements, thermal performance, and budget constraints.

Lightweight Concrete vs Normal Weight Concrete Infographic

materialdif.com

materialdif.com