Plain concrete consists mainly of cement, water, and aggregates, providing adequate compressive strength but limited tensile resistance, making it suitable for non-load-bearing applications. Structural concrete incorporates reinforcing materials such as steel bars or mesh, enhancing its ability to withstand tensile and shear forces, essential for load-bearing structures. Choosing between plain and structural concrete depends on the specific requirements of strength, durability, and load conditions in construction projects.

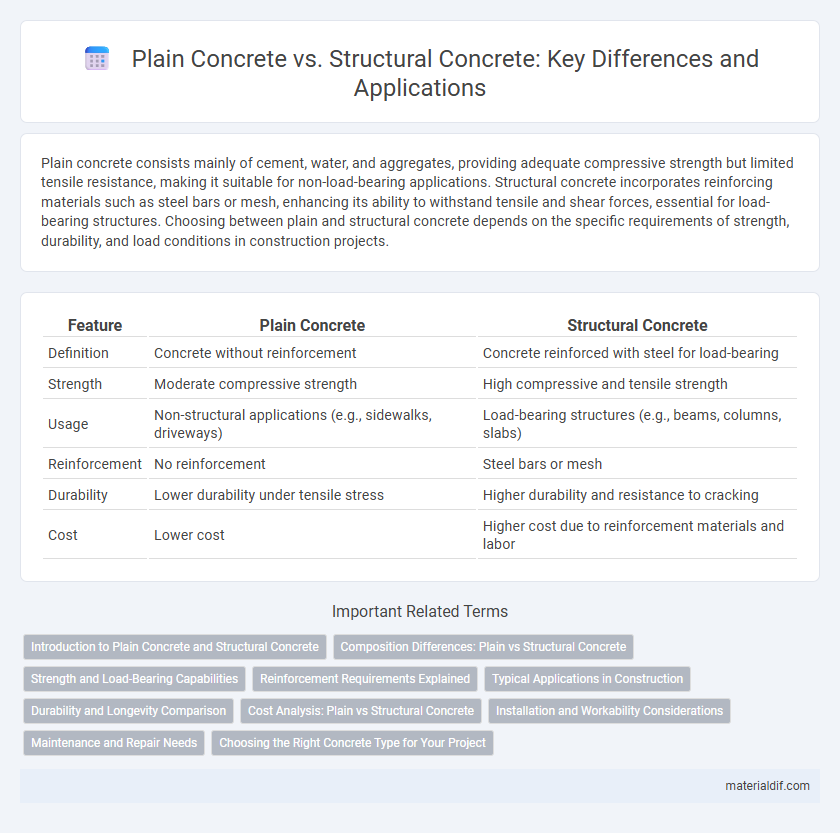

Table of Comparison

| Feature | Plain Concrete | Structural Concrete |

|---|---|---|

| Definition | Concrete without reinforcement | Concrete reinforced with steel for load-bearing |

| Strength | Moderate compressive strength | High compressive and tensile strength |

| Usage | Non-structural applications (e.g., sidewalks, driveways) | Load-bearing structures (e.g., beams, columns, slabs) |

| Reinforcement | No reinforcement | Steel bars or mesh |

| Durability | Lower durability under tensile stress | Higher durability and resistance to cracking |

| Cost | Lower cost | Higher cost due to reinforcement materials and labor |

Introduction to Plain Concrete and Structural Concrete

Plain concrete consists of cement, water, and aggregates without reinforcement, primarily used for non-load-bearing applications such as pavements, floors, and foundations. Structural concrete incorporates steel reinforcement bars, enabling it to withstand tensile, compressive, and shear stresses in buildings, bridges, and other critical structures. The choice between plain and structural concrete depends on load requirements, structural design, and durability considerations in construction projects.

Composition Differences: Plain vs Structural Concrete

Plain concrete primarily consists of cement, water, and fine aggregates, lacking reinforcement materials, which limits its tensile strength and load-bearing capacity. Structural concrete incorporates coarse aggregates and steel reinforcement, enhancing its compressive and tensile strengths to support significant structural loads. The presence of reinforcement bars and a well-graded aggregate mix in structural concrete improves durability and resistance to bending or shear forces compared to plain concrete.

Strength and Load-Bearing Capabilities

Plain concrete, primarily composed of cement, water, and aggregates, exhibits high compressive strength but lacks tensile strength, limiting its load-bearing capabilities in structural applications. Structural concrete incorporates steel reinforcement, significantly enhancing its tensile strength and enabling it to support greater loads and resist bending forces. The load-bearing efficiency of structural concrete makes it essential in constructing beams, columns, and load-bearing walls, where plain concrete would fail under tension or shear stresses.

Reinforcement Requirements Explained

Plain concrete is composed of cement, water, and aggregates without any steel reinforcement, making it suitable for applications where compressive strength is the primary concern, such as sidewalks and pavements. Structural concrete incorporates steel reinforcement like rebar to enhance tensile strength, allowing it to withstand bending and shear stresses in beams, columns, and slabs. Reinforcement requirements in structural concrete are dictated by load-bearing demands, structural design codes, and environmental exposure to prevent cracking and ensure durability.

Typical Applications in Construction

Plain concrete is typically used in non-structural applications such as pavements, flooring, and mass concrete works where tensile strength is not critical. Structural concrete incorporates reinforcement like steel bars, making it essential for load-bearing elements including beams, columns, slabs, and foundations. Choosing the appropriate type ensures safety, durability, and cost-effectiveness in construction projects.

Durability and Longevity Comparison

Plain concrete, composed primarily of cement, water, and aggregates without reinforcement, offers moderate durability but is prone to cracking under tensile stress, limiting its longevity in structural applications. Structural concrete incorporates steel reinforcement, enhancing its tensile strength and resistance to environmental factors such as corrosion and freeze-thaw cycles, thereby significantly improving durability and service life. The synergistic combination of concrete and steel in structural concrete ensures superior performance in load-bearing structures, making it the preferred choice for long-term infrastructure projects.

Cost Analysis: Plain vs Structural Concrete

Plain concrete typically costs less per cubic meter due to its simple mix design and minimal reinforcement requirements, making it ideal for non-load-bearing applications such as pavements and sidewalks. Structural concrete incurs higher costs driven by the inclusion of steel reinforcement, more stringent quality control, and increased labor for formwork and placement, which are essential for supporting loads in beams, columns, and slabs. When performing cost analysis, the decision between plain and structural concrete hinges on project requirements, balancing initial material and labor expenses against necessary structural performance and safety standards.

Installation and Workability Considerations

Plain concrete offers easier installation due to its simple mix and lack of reinforcement, allowing faster placement and finishing on flat surfaces. Structural concrete requires careful handling and placement to ensure proper alignment and support of steel reinforcements, with workability adjusted to maintain cohesion around rebar. Proper vibration and curing practices are critical in structural concrete to avoid voids and ensure strength, while plain concrete requires less stringent measures.

Maintenance and Repair Needs

Plain concrete requires minimal maintenance due to its simple composition and is less prone to structural issues, making repairs infrequent and typically surface-level. Structural concrete, designed to bear loads, demands regular inspections to monitor for cracks, corrosion of reinforcing steel, and potential spalling, necessitating more intensive maintenance and specialized repair techniques. Proper upkeep of structural concrete is critical to ensure safety and prolong the lifespan of load-bearing elements in buildings and infrastructure.

Choosing the Right Concrete Type for Your Project

Plain concrete, composed mainly of cement, water, and coarse aggregate, offers excellent compressive strength for non-load-bearing applications such as pavements and foundations. Structural concrete incorporates steel reinforcement to withstand tensile and bending forces, making it ideal for buildings, bridges, and other load-bearing structures. Selecting the right concrete type depends on the project's load requirements, environmental conditions, and durability needs to ensure safety and longevity.

Plain Concrete vs Structural Concrete Infographic

materialdif.com

materialdif.com