High-strength concrete is primarily characterized by its compressive strength, typically exceeding 6,000 psi, making it ideal for structural components subjected to heavy loads. High-performance concrete, however, encompasses a broader range of properties including durability, workability, and resistance to environmental factors, tailored to specific project requirements. While high-strength concrete focuses on strength alone, high-performance concrete offers a balanced combination of enhanced mechanical and durability characteristics.

Table of Comparison

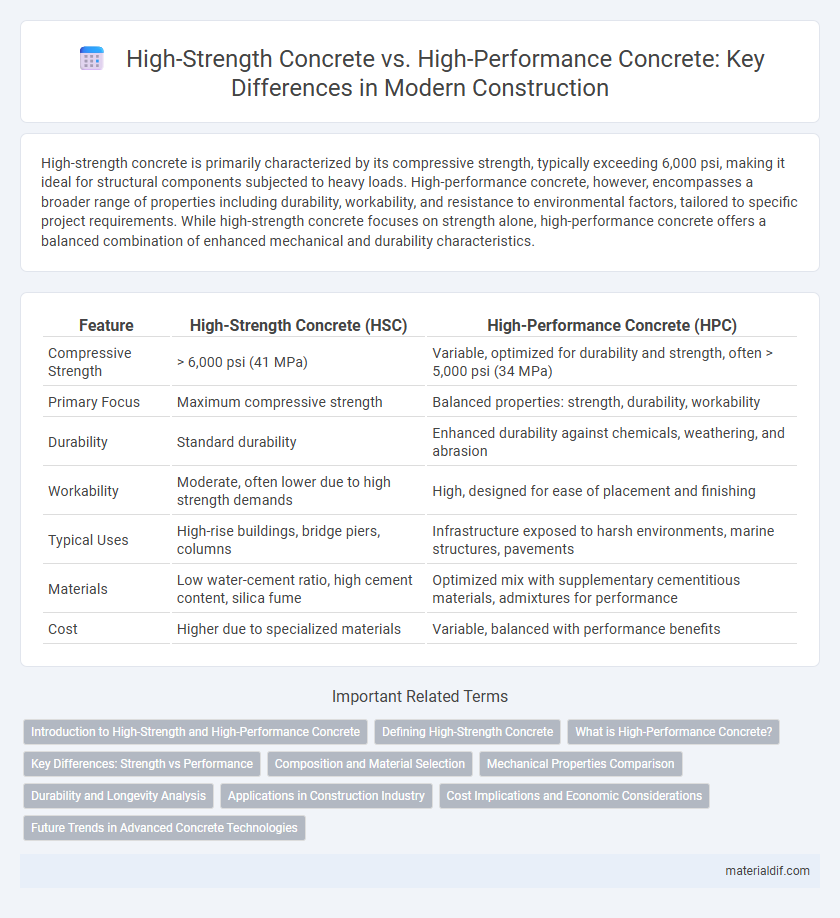

| Feature | High-Strength Concrete (HSC) | High-Performance Concrete (HPC) |

|---|---|---|

| Compressive Strength | > 6,000 psi (41 MPa) | Variable, optimized for durability and strength, often > 5,000 psi (34 MPa) |

| Primary Focus | Maximum compressive strength | Balanced properties: strength, durability, workability |

| Durability | Standard durability | Enhanced durability against chemicals, weathering, and abrasion |

| Workability | Moderate, often lower due to high strength demands | High, designed for ease of placement and finishing |

| Typical Uses | High-rise buildings, bridge piers, columns | Infrastructure exposed to harsh environments, marine structures, pavements |

| Materials | Low water-cement ratio, high cement content, silica fume | Optimized mix with supplementary cementitious materials, admixtures for performance |

| Cost | Higher due to specialized materials | Variable, balanced with performance benefits |

Introduction to High-Strength and High-Performance Concrete

High-strength concrete typically achieves compressive strengths above 6,000 psi (40 MPa), optimized for structural applications requiring superior load-bearing capacity. High-performance concrete encompasses a broader range of enhanced properties, including durability, workability, and resistance to environmental factors, beyond just high compressive strength. Both types use carefully selected materials and mix designs to meet specific engineering requirements in advanced construction projects.

Defining High-Strength Concrete

High-strength concrete is defined by its compressive strength exceeding 6,000 psi (approximately 41 MPa), achieved through a low water-cement ratio and the use of high-quality aggregates and admixtures. This type of concrete is primarily designed for structural applications requiring enhanced load-bearing capacity and durability, such as high-rise buildings and bridges. Its composition enhances mechanical properties but may not necessarily improve other performance aspects like durability or workability.

What is High-Performance Concrete?

High-Performance Concrete (HPC) is a specialized type of concrete designed to exceed standard strength and durability requirements through optimized mix proportions and advanced materials like silica fume, fly ash, and superplasticizers. HPC offers enhanced resistance to environmental factors such as freeze-thaw cycles, chemical attacks, and abrasion, making it ideal for critical infrastructure and demanding construction applications. Its superior workability, reduced permeability, and improved long-term performance differentiate it from conventional and even high-strength concrete varieties.

Key Differences: Strength vs Performance

High-strength concrete primarily emphasizes compressive strength, often exceeding 6,000 psi, making it ideal for structural elements requiring superior load-bearing capacity. High-performance concrete, however, focuses on a broader range of attributes including durability, workability, and resistance to environmental factors such as freeze-thaw cycles and chemical attacks. While high-strength concrete targets maximum strength, high-performance concrete ensures optimized overall performance tailored to specific construction demands.

Composition and Material Selection

High-strength concrete primarily emphasizes a higher compressive strength achieved by using a lower water-cement ratio and incorporating high-quality aggregates and supplementary cementitious materials such as silica fume or fly ash. High-performance concrete, while also possessing high strength, focuses on a broader set of properties including durability, workability, and resistance to environmental factors by optimizing mixture proportions, using advanced admixtures, and selecting refined materials like engineered fine aggregates. Material selection in high-performance concrete often includes polycarboxylate-based superplasticizers and blended cements designed to improve overall performance beyond just strength parameters.

Mechanical Properties Comparison

High-strength concrete (HSC) typically exhibits compressive strengths above 6000 psi, emphasizing enhanced load-bearing capacity and reduced porosity, while high-performance concrete (HPC) combines improved mechanical properties such as durability, workability, and toughness beyond just compressive strength. HSC often has a higher modulus of elasticity and lower creep and shrinkage rates compared to normal concrete, whereas HPC integrates optimized mix designs with supplementary cementitious materials to achieve superior mechanical resilience and resistance to environmental degradation. The mechanical properties of HPC encompass not only strength but also enhanced tensile strength, fracture toughness, and resistance to chemical attack, offering a more balanced structural performance than traditional HSC.

Durability and Longevity Analysis

High-strength concrete typically exhibits compressive strengths above 6,000 psi, enhancing structural load capacity but often sacrificing some durability due to lower permeability and potential micro-cracking. High-performance concrete combines strength with optimized durability through reduced water-cement ratios, advanced admixtures, and improved curing methods, resulting in enhanced resistance to freeze-thaw cycles, chemical attacks, and chloride penetration. Long-term longevity analysis confirms that high-performance concrete structures maintain integrity and serviceability significantly longer than high-strength concrete counterparts under aggressive environmental conditions.

Applications in Construction Industry

High-strength concrete (HSC) is primarily used in structural elements requiring exceptional load-bearing capacity, such as high-rise buildings, bridges, and heavy-duty pavements, owing to its compressive strength above 6,000 psi. High-performance concrete (HPC) offers enhanced durability, workability, and resistance to environmental factors, making it ideal for infrastructure exposed to aggressive conditions like marine structures, tunnels, and industrial facilities. Both HSC and HPC contribute significantly to extending the lifespan and safety of modern construction projects by meeting specific performance criteria beyond conventional concrete.

Cost Implications and Economic Considerations

High-strength concrete often incurs higher material costs due to the use of premium cement, specialized aggregates, and additives aimed at achieving compressive strengths above 6,000 psi. High-performance concrete, while sometimes more expensive initially because of advanced admixtures and rigorous quality control processes, can lead to long-term economic benefits through enhanced durability, reduced maintenance, and extended service life. Evaluating the total cost of ownership reveals that high-performance concrete may offer superior return on investment despite higher upfront expenses.

Future Trends in Advanced Concrete Technologies

High-strength concrete (HSC) focuses on achieving compressive strength beyond 6000 psi, enabling construction of taller, more durable structures, while high-performance concrete (HPC) emphasizes enhanced durability, workability, and sustainability alongside strength. Future trends in advanced concrete technologies include the integration of nano-materials like graphene to improve microstructural properties and the adoption of self-healing concrete that extends service life by autonomously repairing cracks. Innovations in 3D printing and supplementary cementitious materials are driving the transition toward more sustainable and resilient HPC formulations tailored for infrastructure longevity.

High-Strength Concrete vs High-Performance Concrete Infographic

materialdif.com

materialdif.com