Dry-mix shotcrete involves delivering a dry cement and aggregate mixture through a hose, where water is added at the nozzle for immediate application, offering greater control and reduced rebound in overhead or vertical projects. Wet-mix shotcrete, prepared with all ingredients mixed beforehand, allows for faster placement and smoother finishes, making it ideal for large-scale or horizontal surfaces. Choosing between dry-mix and wet-mix shotcrete depends on project scale, site conditions, and the desired application speed and surface quality.

Table of Comparison

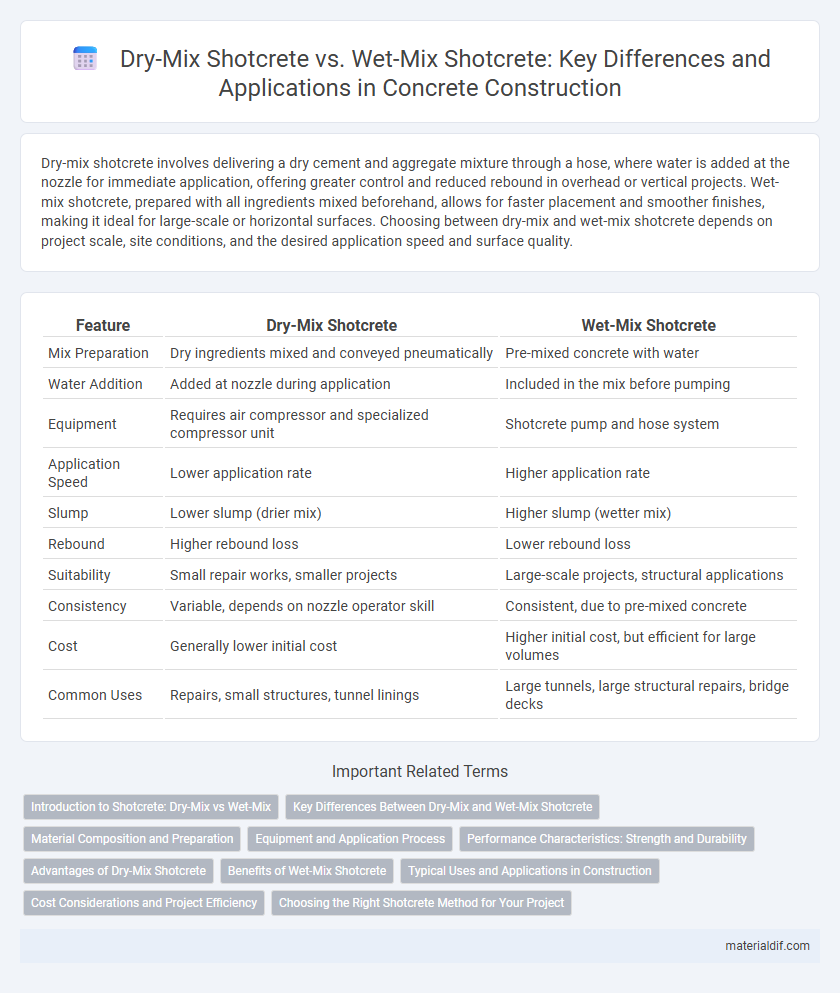

| Feature | Dry-Mix Shotcrete | Wet-Mix Shotcrete |

|---|---|---|

| Mix Preparation | Dry ingredients mixed and conveyed pneumatically | Pre-mixed concrete with water |

| Water Addition | Added at nozzle during application | Included in the mix before pumping |

| Equipment | Requires air compressor and specialized compressor unit | Shotcrete pump and hose system |

| Application Speed | Lower application rate | Higher application rate |

| Slump | Lower slump (drier mix) | Higher slump (wetter mix) |

| Rebound | Higher rebound loss | Lower rebound loss |

| Suitability | Small repair works, smaller projects | Large-scale projects, structural applications |

| Consistency | Variable, depends on nozzle operator skill | Consistent, due to pre-mixed concrete |

| Cost | Generally lower initial cost | Higher initial cost, but efficient for large volumes |

| Common Uses | Repairs, small structures, tunnel linings | Large tunnels, large structural repairs, bridge decks |

Introduction to Shotcrete: Dry-Mix vs Wet-Mix

Shotcrete is a method of applying concrete sprayed at high velocity onto surfaces, used extensively in construction and repair. Dry-mix shotcrete involves mixing dry cement and aggregate with water at the nozzle during application, enabling greater control over water content and reduced rebound. Wet-mix shotcrete combines all ingredients before spraying, offering faster application and improved consistency, making it suitable for larger projects and complex shapes.

Key Differences Between Dry-Mix and Wet-Mix Shotcrete

Dry-mix shotcrete involves delivering dry cement and aggregates through a hose with compressed air, then adding water at the nozzle, offering greater control over water content and reduced rebound. Wet-mix shotcrete uses pre-mixed concrete pumped through a hose and sprayed pneumatically, enabling higher application rates and better suitability for large-scale projects. Key differences include water content control, rebound rates, equipment requirements, and ideal project scale, influencing the selection based on specific construction needs.

Material Composition and Preparation

Dry-mix shotcrete consists of a dry cementitious mixture conveyed through a hose where water is added at the nozzle, allowing for flexible water content control and minimizing rebound material. Wet-mix shotcrete combines pre-mixed concrete with water before being pumped through the hose, resulting in higher flowability and consistent mixture quality. Material composition for dry-mix relies heavily on the operator's skill for water addition, while wet-mix benefits from controlled batching in a plant for optimized aggregate, cement, and admixture proportions.

Equipment and Application Process

Dry-mix shotcrete equipment uses a hopper and compressed air to transport dry material through a delivery hose, with water added at the nozzle, enabling precise control over water content and reducing material waste. Wet-mix shotcrete requires a pump to mix concrete and water prior to delivery, allowing higher volume applications with smoother flow and less rebound. The dry-mix process excels in overhead or vertical placements with intermittent use, while wet-mix is preferred for large-scale projects demanding continuous application and faster placement.

Performance Characteristics: Strength and Durability

Dry-mix shotcrete offers enhanced control over water content during application, resulting in superior early strength development and reduced rebound, optimizing material usage. Wet-mix shotcrete provides consistent mixing and greater uniformity, which contributes to improved long-term durability and resistance to shrinkage cracks. Both methods achieve high compressive strength, but wet-mix shotcrete excels in large-scale projects requiring thorough material homogeneity and durability against environmental exposure.

Advantages of Dry-Mix Shotcrete

Dry-mix shotcrete offers superior control over water content, allowing precise adjustment at the nozzle, which reduces rebound and enhances material conservation. This method enables easier portability and setup, making it ideal for projects with limited access or small-scale applications. Additionally, dry-mix shotcrete provides faster start-stop capability, improving efficiency on jobs requiring intermittent application or high adaptability.

Benefits of Wet-Mix Shotcrete

Wet-mix shotcrete offers superior workability and consistent material quality due to its pre-mixed concrete components, enhancing placement speed and reducing rebound waste. This method provides improved control over water content, leading to higher compressive strength and durability in structural applications. Wet-mix shotcrete is particularly effective for large-scale projects and overhead spraying, ensuring better adherence and reduced labor costs.

Typical Uses and Applications in Construction

Dry-mix shotcrete is typically used for repair work, tunneling, and small-scale projects where precise control over water content is essential, making it ideal for overhead and vertical surfaces. Wet-mix shotcrete suits large-scale applications such as structural repairs, swimming pools, and slope stabilization due to its higher production rate and better consistency. Both methods are effective in reinforcing concrete structures but are selected based on project scale, application complexity, and material handling requirements.

Cost Considerations and Project Efficiency

Dry-mix shotcrete typically involves lower initial equipment costs and offers greater control over the mix at the nozzle, reducing material waste on smaller or remote projects, enhancing project efficiency. Wet-mix shotcrete generally incurs higher upfront pumping and equipment expenses but enables faster placement rates and continuous operation, which can significantly lower labor costs for large-scale applications. Evaluating project size, accessibility, and labor availability is essential to optimize cost effectiveness and overall efficiency between dry-mix and wet-mix shotcrete methods.

Choosing the Right Shotcrete Method for Your Project

Dry-mix shotcrete offers superior control over water content, making it ideal for repair and overhead applications where precision is critical. Wet-mix shotcrete provides faster placement and better workability, benefiting large-scale projects with extensive coverage requirements. Selecting the right shotcrete method depends on project size, complexity, environmental conditions, and desired setting time to ensure structural integrity and optimal performance.

Dry-Mix Shotcrete vs Wet-Mix Shotcrete Infographic

materialdif.com

materialdif.com