Portland cement concrete offers high early strength and durability, making it ideal for structural applications requiring rapid load-bearing capacity. Blended cement concrete incorporates supplementary cementitious materials like fly ash or slag, enhancing long-term strength, reducing permeability, and improving sustainability by lowering cement content. Choosing between these types depends on performance requirements, environmental considerations, and project specifications.

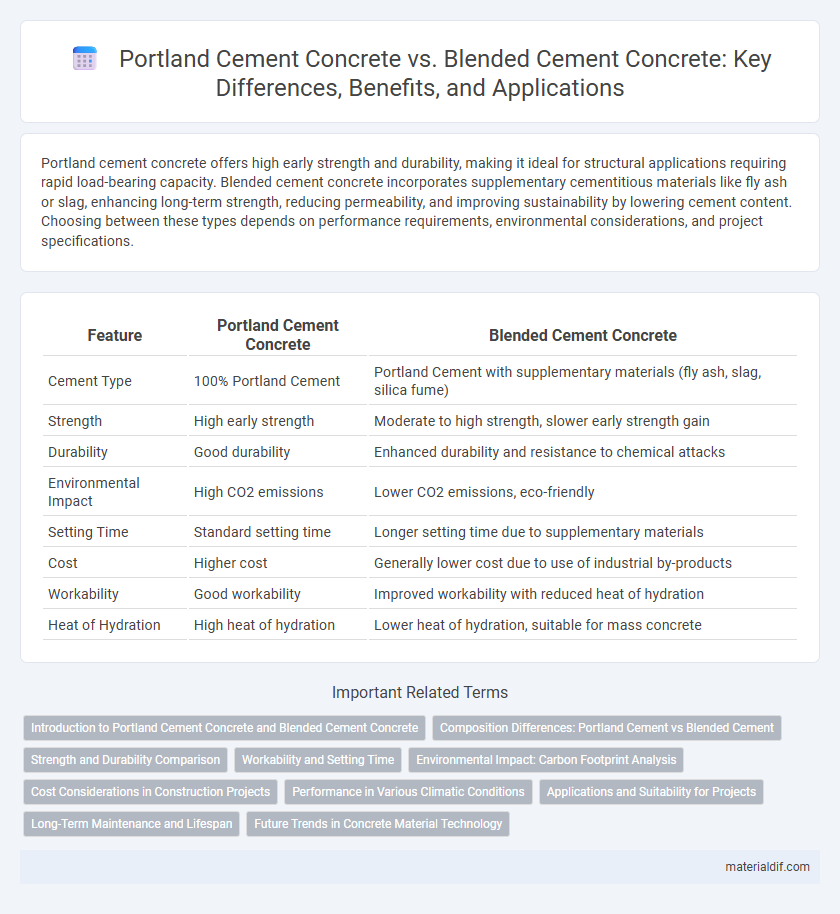

Table of Comparison

| Feature | Portland Cement Concrete | Blended Cement Concrete |

|---|---|---|

| Cement Type | 100% Portland Cement | Portland Cement with supplementary materials (fly ash, slag, silica fume) |

| Strength | High early strength | Moderate to high strength, slower early strength gain |

| Durability | Good durability | Enhanced durability and resistance to chemical attacks |

| Environmental Impact | High CO2 emissions | Lower CO2 emissions, eco-friendly |

| Setting Time | Standard setting time | Longer setting time due to supplementary materials |

| Cost | Higher cost | Generally lower cost due to use of industrial by-products |

| Workability | Good workability | Improved workability with reduced heat of hydration |

| Heat of Hydration | High heat of hydration | Lower heat of hydration, suitable for mass concrete |

Introduction to Portland Cement Concrete and Blended Cement Concrete

Portland Cement Concrete primarily consists of Portland cement, aggregates, and water, known for its high early strength and durability in construction projects. Blended Cement Concrete incorporates supplementary cementitious materials such as fly ash, slag, or silica fume, enhancing workability and long-term strength while reducing environmental impact. Both types serve crucial roles in infrastructure, with Portland cement offering rapid setting properties and blended cement improving sustainability and resistance to chemical attacks.

Composition Differences: Portland Cement vs Blended Cement

Portland cement concrete primarily consists of Portland cement clinker, gypsum, and minor additives, providing high early strength and rapid setting characteristics. Blended cement concrete incorporates supplementary cementitious materials (SCMs) such as fly ash, slag, or silica fume, which enhance durability, reduce permeability, and lower the carbon footprint. The composition differences influence hydration rates, mechanical properties, and environmental impact, making blended cement concrete preferred for sustainable construction.

Strength and Durability Comparison

Portland cement concrete typically exhibits higher early strength due to its pure clinker composition, allowing for rapid load-bearing capacity development compared to blended cement concrete. Blended cement concrete enhances long-term durability by incorporating supplementary cementitious materials like fly ash or slag, which improve resistance to sulfate attack, alkali-silica reaction, and reduce permeability. While Portland cement concrete excels in initial strength parameters, blended cement concrete offers superior performance in aggressive environmental conditions, making it ideal for sustainable and durable infrastructure projects.

Workability and Setting Time

Portland cement concrete offers high early strength and faster setting time, making it ideal for projects requiring quick turnaround. Blended cement concrete, incorporating supplementary materials like fly ash or slag, generally improves workability by enhancing the mix's cohesiveness and reducing water demand. The extended setting time in blended cement mixes allows for better placement and finishing, particularly in hot weather or large pours.

Environmental Impact: Carbon Footprint Analysis

Portland cement concrete typically exhibits a higher carbon footprint due to the extensive energy-intensive calcination of limestone and clinker production, releasing significant CO2 emissions. Blended cement concrete lowers environmental impact by incorporating supplementary cementitious materials such as fly ash or slag, which reduce clinker content and associated greenhouse gases. Lifecycle assessments highlight that blended cements can cut carbon emissions by up to 30-50%, making them a more sustainable choice for construction projects.

Cost Considerations in Construction Projects

Portland Cement Concrete generally incurs higher costs due to the exclusive use of Ordinary Portland Cement, whereas Blended Cement Concrete leverages supplementary cementitious materials like fly ash or slag, reducing cement consumption and overall expenses. The substitution in Blended Cement Concrete lowers both material costs and environmental impact, contributing to budget efficiency in large-scale construction projects. Contractors often prefer Blended Cement Concrete for its cost-effectiveness, improved durability, and sustainability benefits in infrastructure development.

Performance in Various Climatic Conditions

Portland Cement Concrete demonstrates high early strength development but may be prone to thermal cracking in extreme temperatures due to its heat of hydration. Blended Cement Concrete, incorporating supplementary cementitious materials like fly ash or slag, offers improved durability and resistance to chemical attack in aggressive environments, enhancing long-term performance in diverse climatic conditions. The use of blended cement reduces permeability and improves resistance to sulfate and chloride ingress, making it ideal for coastal and industrial areas with fluctuating weather patterns.

Applications and Suitability for Projects

Portland cement concrete offers high early strength and is ideal for structural applications like foundations, bridges, and pavements where rapid strength gain is crucial. Blended cement concrete, incorporating supplementary materials such as fly ash or slag, enhances durability, reduces permeability, and is suitable for mass concrete, marine structures, and environmentally sustainable projects. The choice depends on project requirements, with Portland cement favored for fast construction and blended cement preferred for long-term performance and ecological benefits.

Long-Term Maintenance and Lifespan

Portland cement concrete typically demonstrates higher early strength but may be more susceptible to chemical attacks and shrinkage over time, leading to increased long-term maintenance needs. Blended cement concrete, incorporating supplementary cementitious materials like fly ash or slag, offers enhanced durability, reduced permeability, and improved resistance to sulfate and alkali-silica reactions, thereby extending the lifespan of structures. Projects requiring minimal maintenance and superior longevity often benefit from blended cement concrete due to its improved microstructure and resilience against environmental degradation.

Future Trends in Concrete Material Technology

Portland Cement Concrete remains the dominant material in construction due to its high compressive strength and durability, but future trends highlight significant advancements in Blended Cement Concrete incorporating supplementary cementitious materials like fly ash, slag, and silica fume to enhance sustainability and reduce carbon footprints. Innovations in nanotechnology and geopolymer blends are projected to improve the mechanical properties and longevity of concrete while minimizing environmental impact. The integration of smart sensors and AI-driven mixing processes further optimizes quality control, signaling a transformative shift towards greener, more resilient concrete materials.

Portland Cement Concrete vs Blended Cement Concrete Infographic

materialdif.com

materialdif.com