Post-tensioned concrete involves casting concrete first and then tensioning the steel tendons with hydraulic jacks after it has hardened, which allows for longer spans and thinner slabs. Pre-tensioned concrete requires steel tendons to be tensioned before casting, with the concrete bonding to the stressed steel as it cures, providing higher early strength and efficient load distribution. The choice between post-tensioned and pre-tensioned concrete depends on project requirements like span length, construction speed, and structural performance.

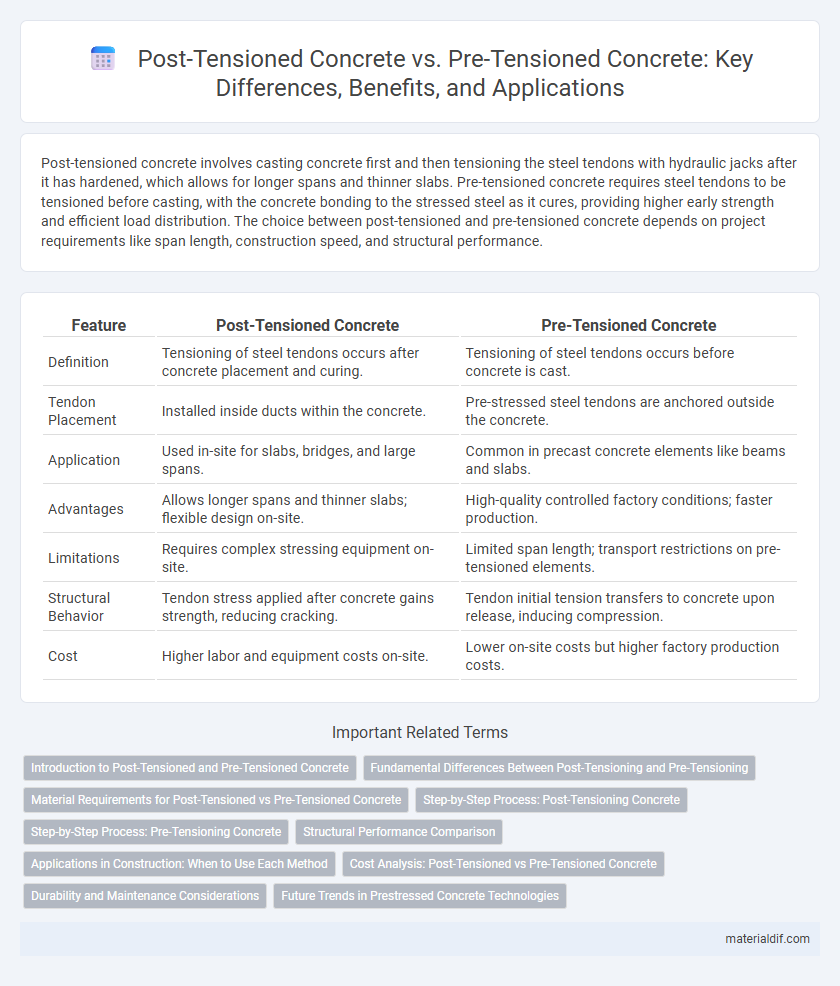

Table of Comparison

| Feature | Post-Tensioned Concrete | Pre-Tensioned Concrete |

|---|---|---|

| Definition | Tensioning of steel tendons occurs after concrete placement and curing. | Tensioning of steel tendons occurs before concrete is cast. |

| Tendon Placement | Installed inside ducts within the concrete. | Pre-stressed steel tendons are anchored outside the concrete. |

| Application | Used in-site for slabs, bridges, and large spans. | Common in precast concrete elements like beams and slabs. |

| Advantages | Allows longer spans and thinner slabs; flexible design on-site. | High-quality controlled factory conditions; faster production. |

| Limitations | Requires complex stressing equipment on-site. | Limited span length; transport restrictions on pre-tensioned elements. |

| Structural Behavior | Tendon stress applied after concrete gains strength, reducing cracking. | Tendon initial tension transfers to concrete upon release, inducing compression. |

| Cost | Higher labor and equipment costs on-site. | Lower on-site costs but higher factory production costs. |

Introduction to Post-Tensioned and Pre-Tensioned Concrete

Post-tensioned concrete involves casting concrete first and then tensioning steel tendons within ducts after the concrete hardens, enhancing structural capacity and reducing crack widths. Pre-tensioned concrete requires tensioning steel strands before pouring concrete, bonding the strands to concrete upon curing, commonly used in precast elements like beams and slabs. Both methods improve concrete's tensile strength but differ in application timing, tendon placement, and suitable structural uses.

Fundamental Differences Between Post-Tensioning and Pre-Tensioning

Post-tensioned concrete involves tensioning the steel tendons after the concrete has cured, allowing for greater flexibility in design and longer spans. Pre-tensioned concrete requires tensioning the steel strands before the concrete is poured, creating high initial compressive stresses that enhance structural performance but limit component size. The fundamental difference lies in the timing of tendon tensioning, impacting construction methods, structural behavior, and application suitability.

Material Requirements for Post-Tensioned vs Pre-Tensioned Concrete

Post-tensioned concrete requires high-strength steel tendons that remain unbonded within ducts, allowing for tensioning after concrete curing, whereas pre-tensioned concrete uses pre-tensioned steel wires embedded and bonded within the concrete. The duct material in post-tensioned systems must resist corrosion and provide smooth tendon movement, often employing galvanized or plastic-coated sheathing. In contrast, pre-tensioned concrete relies on more rigid forms and anchorage systems since steel wires are tensioned before casting, reducing the need for ducts but increasing formwork complexity.

Step-by-Step Process: Post-Tensioning Concrete

Post-tensioning concrete involves casting the concrete slab with ducts or sleeves in place, allowing high-strength steel tendons to be threaded through these channels after the concrete reaches a specified strength. The tendons are then tensioned using hydraulic jacks, applying a compressive force that counteracts tensile stresses in the concrete, enhancing durability and load capacity. Finally, the tensioned tendons are anchored securely, and the ducts are often filled with grout to protect against corrosion and ensure bond between the tendons and concrete.

Step-by-Step Process: Pre-Tensioning Concrete

Pre-tensioning concrete involves stretching high-strength steel tendons between anchored beams before concrete pouring, ensuring maximum tensile strength. Once the concrete is cast and reaches adequate strength, the tension is released, transferring stress from the tendons to the concrete, enhancing durability and load capacity. This method requires precise placement and curing time to achieve the optimal bond between steel and concrete for structural efficiency.

Structural Performance Comparison

Post-tensioned concrete offers superior structural performance by allowing longer spans and thinner slabs due to the application of tension after concrete curing, which reduces cracking and enhances load-bearing capacity. Pre-tensioned concrete, with strands tensioned before casting, excels in repetitive elements like beams and slabs but is limited by strand anchorage during casting. Both methods improve strength and durability, yet post-tensioning provides greater flexibility in design and improved resistance to service loads and environmental factors.

Applications in Construction: When to Use Each Method

Post-tensioned concrete is ideal for large-scale structures like bridges, parking garages, and long-span floor slabs due to its ability to accommodate complex shapes and provide greater tensile strength after casting. Pre-tensioned concrete is commonly used in precast elements such as beams, slabs, and railway sleepers, where high production efficiency and controlled factory conditions are essential. Choosing between post-tensioning and pre-tensioning depends on factors like site constraints, design flexibility, and the structural performance required for specific construction applications.

Cost Analysis: Post-Tensioned vs Pre-Tensioned Concrete

Post-tensioned concrete generally offers cost savings in larger spans and complex structural designs due to reduced material usage and faster construction times compared to pre-tensioned concrete. Pre-tensioned concrete tends to have lower upfront material and fabrication costs but may incur higher labor expenses and limitations in design flexibility. Optimizing project-specific factors such as span length, load requirements, and construction schedule can influence the overall cost-efficiency between post-tensioned and pre-tensioned concrete systems.

Durability and Maintenance Considerations

Post-tensioned concrete offers superior durability due to its ability to control cracking through active tensioning, reducing water infiltration and corrosion risks, which lowers maintenance requirements over time. Pre-tensioned concrete, while also durable, is more susceptible to early-stage microcracking since the tendons are stressed before casting, potentially necessitating more frequent inspections and upkeep. Both methods use high-strength steel tendons, but post-tensioned systems generally provide enhanced long-term performance in environments exposed to heavy loads and harsh conditions.

Future Trends in Prestressed Concrete Technologies

Future trends in prestressed concrete technologies emphasize advances in materials such as high-performance steel strands and innovative corrosion-resistant coatings to enhance durability and longevity. Integration of smart sensors for real-time structural health monitoring is becoming more prominent in both post-tensioned and pre-tensioned concrete applications. Emerging computational modeling techniques are optimizing tendon layout and stress distribution, leading to improved efficiency and sustainability in construction practices.

Post-Tensioned Concrete vs Pre-Tensioned Concrete Infographic

materialdif.com

materialdif.com