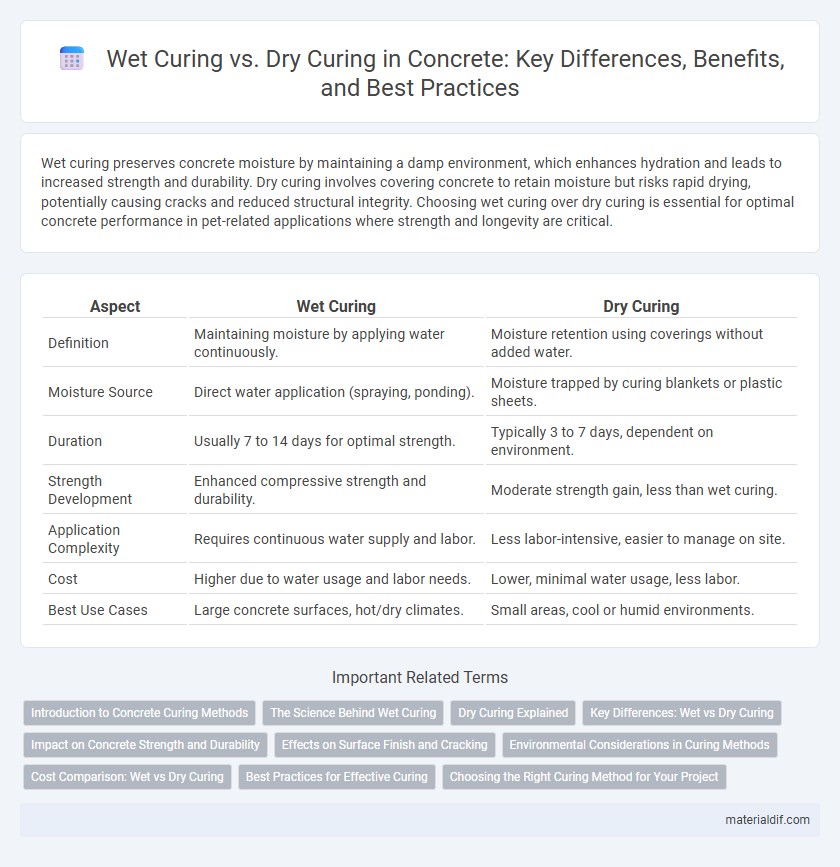

Wet curing preserves concrete moisture by maintaining a damp environment, which enhances hydration and leads to increased strength and durability. Dry curing involves covering concrete to retain moisture but risks rapid drying, potentially causing cracks and reduced structural integrity. Choosing wet curing over dry curing is essential for optimal concrete performance in pet-related applications where strength and longevity are critical.

Table of Comparison

| Aspect | Wet Curing | Dry Curing |

|---|---|---|

| Definition | Maintaining moisture by applying water continuously. | Moisture retention using coverings without added water. |

| Moisture Source | Direct water application (spraying, ponding). | Moisture trapped by curing blankets or plastic sheets. |

| Duration | Usually 7 to 14 days for optimal strength. | Typically 3 to 7 days, dependent on environment. |

| Strength Development | Enhanced compressive strength and durability. | Moderate strength gain, less than wet curing. |

| Application Complexity | Requires continuous water supply and labor. | Less labor-intensive, easier to manage on site. |

| Cost | Higher due to water usage and labor needs. | Lower, minimal water usage, less labor. |

| Best Use Cases | Large concrete surfaces, hot/dry climates. | Small areas, cool or humid environments. |

Introduction to Concrete Curing Methods

Wet curing involves maintaining concrete moisture through methods like water spraying, ponding, or covering with wet burlap to promote continued hydration and strength development. Dry curing relies on sealing the concrete surface using membranes or plastic sheets to retain internal moisture, preventing evaporation and shrinkage. Both methods enhance concrete durability and structural integrity by optimizing moisture retention during the critical curing period.

The Science Behind Wet Curing

Wet curing enhances concrete strength by maintaining optimal moisture levels, promoting continuous hydration of cement particles. This process reduces microcracking and improves the density and durability of the concrete matrix. Studies show that properly wet-cured concrete can achieve up to 20% higher compressive strength compared to dry-cured counterparts.

Dry Curing Explained

Dry curing involves maintaining adequate moisture in concrete by minimizing water evaporation through methods such as covering the surface with plastic sheeting, applying curing compounds, or using damp curing blankets. This process prevents shrinkage cracks and ensures proper hydration of cement, leading to improved strength and durability in the final concrete structure. Dry curing is particularly beneficial in arid or wind-prone environments where water retention is challenging, optimizing concrete performance without the need for continuous water immersion.

Key Differences: Wet vs Dry Curing

Wet curing maintains concrete moisture by continuously applying water or covering it with wet materials, enhancing hydration and strength development. Dry curing relies on ambient humidity and surface water retention, often resulting in slower strength gain and increased risk of surface cracking. Wet curing typically achieves higher compressive strength and durability compared to dry curing due to more consistent moisture supply.

Impact on Concrete Strength and Durability

Wet curing significantly enhances concrete strength by maintaining adequate moisture levels, which promotes proper hydration of cement particles and reduces microcracking. In contrast, dry curing often leads to insufficient moisture, resulting in lower compressive strength and increased susceptibility to surface crazing and shrinkage cracks. Proper wet curing extends concrete durability by improving resistance to freeze-thaw cycles, chemical attacks, and abrasion, making it essential for long-lasting structural performance.

Effects on Surface Finish and Cracking

Wet curing enhances concrete's surface finish by maintaining moisture, resulting in fewer surface cracks and a denser, smoother texture. Dry curing often leads to rapid moisture loss, increasing the likelihood of surface shrinkage cracks and a rougher, more porous finish. Proper wet curing techniques significantly improve durability and reduce microcracking on the concrete surface.

Environmental Considerations in Curing Methods

Wet curing reduces concrete shrinkage and improves durability by maintaining optimal moisture levels, but it demands significant water consumption and can increase environmental impact in water-scarce regions. Dry curing uses less water, minimizing resource depletion, yet it may lead to less effective hydration and higher risk of cracking, impacting the structure's longevity and increasing maintenance needs. Choosing the appropriate curing method requires balancing water conservation with desired concrete performance to optimize environmental sustainability.

Cost Comparison: Wet vs Dry Curing

Wet curing involves maintaining moisture on concrete surfaces through methods like water spraying or wet coverings, resulting in higher labor and water expenses compared to dry curing. Dry curing methods, such as using curing compounds or sealed enclosures, reduce water usage and labor costs but may risk lower final strength if not properly managed. Overall, dry curing typically offers cost savings in water and labor but requires careful application to ensure concrete durability and performance.

Best Practices for Effective Curing

Effective concrete curing involves maintaining optimal moisture levels and temperature to ensure proper hydration and strength development. Wet curing methods, such as continuous water spraying or covering with wet burlap, provide consistent moisture to prevent surface cracking and enhance durability. Dry curing techniques require sealing the concrete surface with curing compounds to retain internal moisture, balancing moisture preservation with practical site conditions.

Choosing the Right Curing Method for Your Project

Wet curing maintains concrete moisture by continuous water application, enhancing hydration and increasing strength development, especially for large slabs and structures exposed to harsh environments. Dry curing relies on sealing moisture within freshly poured concrete using membranes or plastic sheets, suitable for indoor projects with controlled humidity but may risk surface cracking if poorly managed. Selecting the appropriate curing method depends on project scale, environmental conditions, and desired durability to optimize concrete performance and longevity.

Wet Curing vs Dry Curing Infographic

materialdif.com

materialdif.com