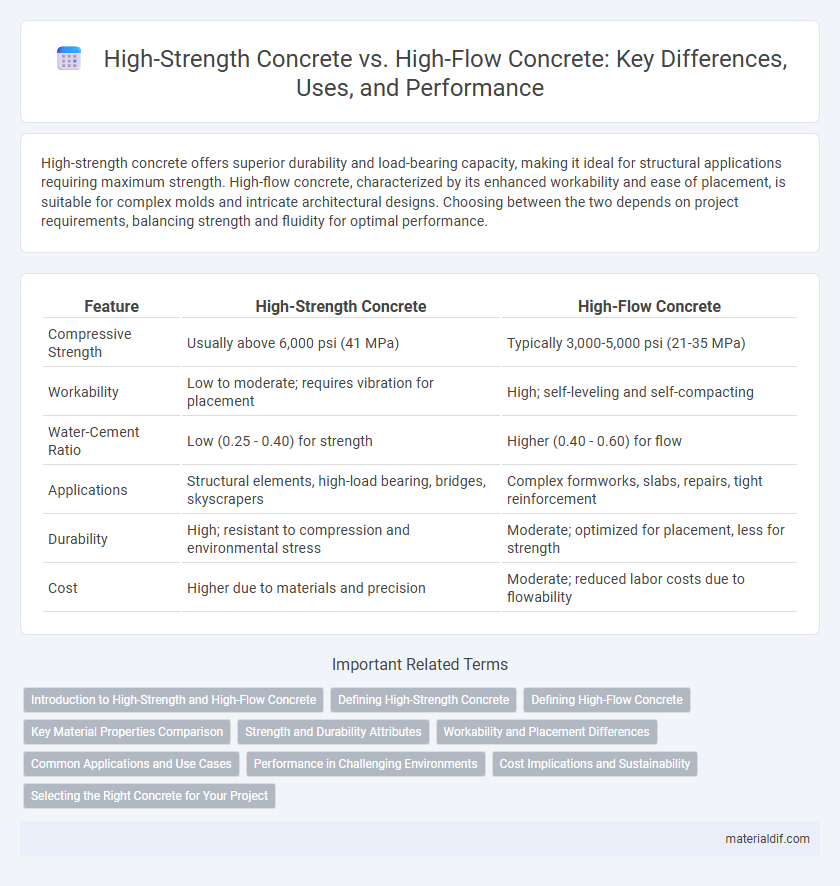

High-strength concrete offers superior durability and load-bearing capacity, making it ideal for structural applications requiring maximum strength. High-flow concrete, characterized by its enhanced workability and ease of placement, is suitable for complex molds and intricate architectural designs. Choosing between the two depends on project requirements, balancing strength and fluidity for optimal performance.

Table of Comparison

| Feature | High-Strength Concrete | High-Flow Concrete |

|---|---|---|

| Compressive Strength | Usually above 6,000 psi (41 MPa) | Typically 3,000-5,000 psi (21-35 MPa) |

| Workability | Low to moderate; requires vibration for placement | High; self-leveling and self-compacting |

| Water-Cement Ratio | Low (0.25 - 0.40) for strength | Higher (0.40 - 0.60) for flow |

| Applications | Structural elements, high-load bearing, bridges, skyscrapers | Complex formworks, slabs, repairs, tight reinforcement |

| Durability | High; resistant to compression and environmental stress | Moderate; optimized for placement, less for strength |

| Cost | Higher due to materials and precision | Moderate; reduced labor costs due to flowability |

Introduction to High-Strength and High-Flow Concrete

High-strength concrete achieves compressive strengths typically above 6,000 psi through optimized mix designs incorporating low water-cement ratios and advanced admixtures, making it ideal for structural applications requiring enhanced durability and load-bearing capacity. High-flow concrete, also known as self-consolidating concrete, features high workability and fluidity, allowing it to flow easily into complex forms without mechanical vibration, improving placement efficiency and surface finish quality. Both types offer distinct advantages in construction, with high-strength concrete emphasizing structural performance and high-flow concrete prioritizing ease of placement.

Defining High-Strength Concrete

High-strength concrete is characterized by its compressive strength exceeding 6,000 psi, achieved through a precise mix of low water-to-cement ratio and high-quality materials like silica fume and superplasticizers. This type of concrete is engineered to provide enhanced durability, load-bearing capacity, and resistance to environmental stressors, making it ideal for high-rise buildings and infrastructure projects requiring significant structural integrity. Unlike high-flow concrete, which prioritizes workability and ease of placement, high-strength concrete emphasizes mechanical performance and long-term resilience.

Defining High-Flow Concrete

High-flow concrete, also known as self-leveling or self-consolidating concrete, is designed to spread and fill complex formworks with minimal vibration due to its high flowability and excellent workability. It contains superplasticizers and viscosity-modifying admixtures to enhance its fluidity while maintaining strength and durability. Unlike high-strength concrete, which prioritizes compressive strength, high-flow concrete emphasizes ease of placement and surface finish quality in intricate construction applications.

Key Material Properties Comparison

High-strength concrete exhibits compressive strengths typically exceeding 6,000 psi, characterized by low water-cement ratios and dense microstructure, enhancing durability and load-bearing capacity. High-flow concrete, also known as self-consolidating concrete, emphasizes high workability with slump flow values ranging from 18 to 30 inches, achieved through superplasticizers and viscosity-modifying agents while maintaining moderate strength levels around 4,000 to 5,500 psi. The critical material properties comparison highlights that high-strength concrete prioritizes mechanical performance and structural resilience, whereas high-flow concrete focuses on improved placement efficiency and surface finish quality without compromising essential strength parameters.

Strength and Durability Attributes

High-strength concrete achieves compressive strengths often exceeding 6000 psi, making it ideal for load-bearing structures requiring superior durability and resistance to environmental stressors. High-flow concrete, characterized by its enhanced workability and flowability, facilitates easier placement in complex formworks and dense reinforcement areas while maintaining adequate strength levels typically around 4000 to 5000 psi. The durability of high-strength concrete is generally higher due to its dense microstructure, whereas high-flow concrete balances strength with improved application efficiency, crucial for projects demanding both strength and ease of construction.

Workability and Placement Differences

High-strength concrete typically exhibits lower workability due to its reduced water-to-cement ratio, making placement more challenging compared to high-flow concrete, which is designed for superior fluidity and ease of placement without segregation. High-flow concrete often incorporates superplasticizers and optimized aggregate grading to enhance slump values beyond 200 mm, allowing it to flow effortlessly into complex formworks and congested reinforcement. The higher workability of high-flow concrete reduces labor intensity and improves surface finish, while high-strength concrete prioritizes mechanical properties requiring more careful handling during placement.

Common Applications and Use Cases

High-strength concrete is commonly used in structural components such as high-rise buildings, bridges, and heavy-duty pavements where enhanced durability and load-bearing capacity are critical. High-flow concrete, often referred to as self-compacting concrete, is preferred in applications requiring complex forms, dense reinforcement, and rapid placement like precast elements and intricate architectural designs. Both types optimize performance but address distinct construction challenges based on strength and workability requirements.

Performance in Challenging Environments

High-strength concrete exhibits superior compressive strength exceeding 10,000 psi, making it ideal for load-bearing structures in seismic or high-stress environments. High-flow concrete, characterized by its enhanced workability and self-leveling properties, excels in casting complex forms and ensuring thorough compaction without segregation in intricate molds. In extreme conditions such as marine or freeze-thaw cycles, high-strength concrete offers durability and crack resistance, whereas high-flow concrete ensures uniform density and minimizes voids, improving long-term performance.

Cost Implications and Sustainability

High-strength concrete typically incurs higher material and production costs due to the extensive use of cement and additives, impacting overall project budgets but offering enhanced durability and reduced maintenance expenses. High-flow concrete, while generally more cost-effective and easier to place, may require increased cement content and admixtures to achieve flowability, influencing carbon footprint and sustainability metrics. Selecting between the two involves balancing upfront costs with long-term environmental impacts, considering factors like embodied carbon, energy consumption, and lifecycle performance.

Selecting the Right Concrete for Your Project

High-strength concrete offers superior compressive strength, making it ideal for structural elements requiring load-bearing capacity such as columns, beams, and slabs in high-rise buildings and infrastructure projects. High-flow concrete, also known as self-compacting concrete, excels in applications needing easy placement and consolidation without mechanical vibration, perfect for complex formworks and densely reinforced sections. Choosing the right concrete depends on project requirements--prioritize high-strength concrete for durability and load support, while high-flow concrete enhances efficiency and surface finish in intricate designs.

High-Strength Concrete vs High-Flow Concrete Infographic

materialdif.com

materialdif.com