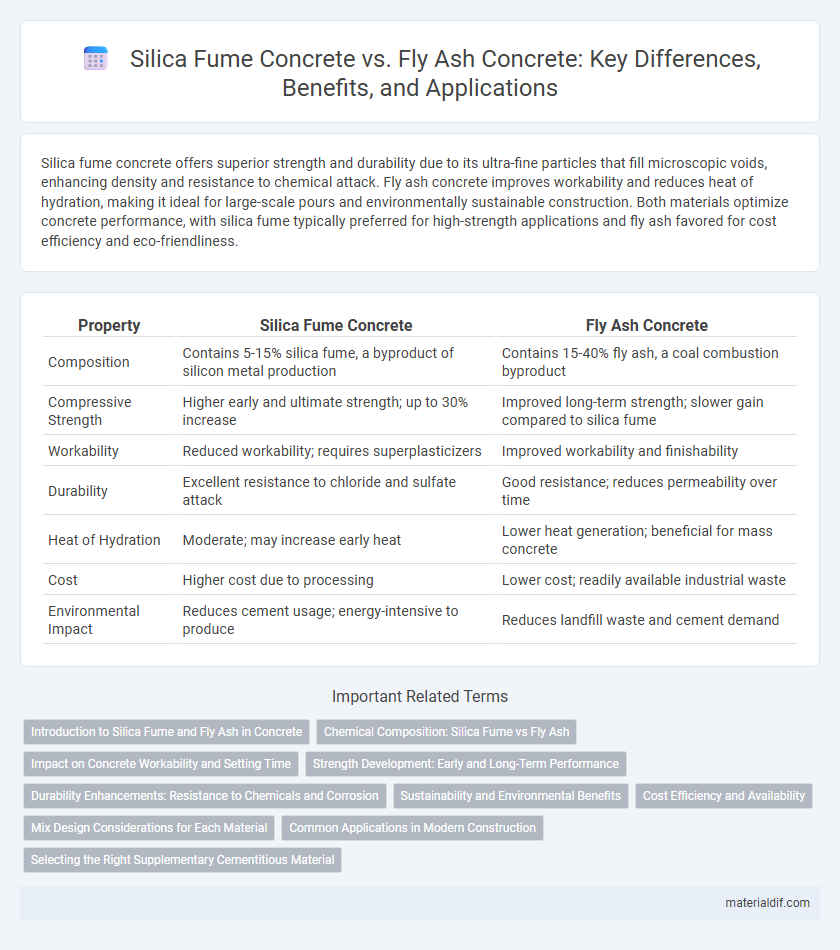

Silica fume concrete offers superior strength and durability due to its ultra-fine particles that fill microscopic voids, enhancing density and resistance to chemical attack. Fly ash concrete improves workability and reduces heat of hydration, making it ideal for large-scale pours and environmentally sustainable construction. Both materials optimize concrete performance, with silica fume typically preferred for high-strength applications and fly ash favored for cost efficiency and eco-friendliness.

Table of Comparison

| Property | Silica Fume Concrete | Fly Ash Concrete |

|---|---|---|

| Composition | Contains 5-15% silica fume, a byproduct of silicon metal production | Contains 15-40% fly ash, a coal combustion byproduct |

| Compressive Strength | Higher early and ultimate strength; up to 30% increase | Improved long-term strength; slower gain compared to silica fume |

| Workability | Reduced workability; requires superplasticizers | Improved workability and finishability |

| Durability | Excellent resistance to chloride and sulfate attack | Good resistance; reduces permeability over time |

| Heat of Hydration | Moderate; may increase early heat | Lower heat generation; beneficial for mass concrete |

| Cost | Higher cost due to processing | Lower cost; readily available industrial waste |

| Environmental Impact | Reduces cement usage; energy-intensive to produce | Reduces landfill waste and cement demand |

Introduction to Silica Fume and Fly Ash in Concrete

Silica fume, a byproduct of silicon metal production, is characterized by its ultra-fine particles and high pozzolanic activity, enhancing concrete's strength and durability by filling microscopic voids. Fly ash, a coal combustion residue, improves workability and reduces permeability in concrete through its spherical particles and latent hydraulic properties. Both materials modify the microstructure of concrete, contributing to improved mechanical performance and long-term stability.

Chemical Composition: Silica Fume vs Fly Ash

Silica fume concrete contains a high percentage of amorphous silicon dioxide (SiO2), typically around 85-95%, which enhances its pozzolanic reactivity and contributes to its superior strength and durability. Fly ash concrete, derived from coal combustion, has a variable chemical composition with SiO2 content ranging from 40-60%, along with significant amounts of alumina (Al2O3) and iron oxide (Fe2O3), offering improved workability and moderate strength gain. The distinct chemical makeup of silica fume promotes rapid formation of calcium silicate hydrate (C-S-H), whereas fly ash's blend of oxides supports long-term strength development and enhanced resistance to sulfate attack.

Impact on Concrete Workability and Setting Time

Silica fume concrete typically exhibits reduced workability due to the ultrafine particles increasing water demand, requiring superplasticizers to maintain flowability, while fly ash concrete generally improves workability by acting as a lubricant within the mix. The setting time of silica fume concrete is often accelerated because of its high pozzolanic activity, whereas fly ash concrete tends to have longer setting times, contributing to slower strength development in early stages. These differences significantly influence construction scheduling and formwork removal timing in concrete applications.

Strength Development: Early and Long-Term Performance

Silica fume concrete exhibits superior early strength development due to its fine particles filling voids and accelerating pozzolanic reactions, achieving compressive strengths up to 20-30% higher within the first 7 days compared to standard mixes. Fly ash concrete shows slower initial strength gain but enhances long-term strength and durability by continuing pozzolanic activity over months, often surpassing ordinary Portland cement concrete after 28 days. The choice between silica fume and fly ash depends on project requirements for early load bearing versus long-term performance and resistance to chemical attack.

Durability Enhancements: Resistance to Chemicals and Corrosion

Silica fume concrete exhibits superior durability enhancements with increased resistance to chemical attacks and corrosion due to its dense microstructure and pozzolanic reaction that reduces permeability. Fly ash concrete also improves chemical resistance by refining pore structure and reducing calcium hydroxide content, which lowers susceptibility to sulfate and chloride ingress. Comparative studies show silica fume concrete typically outperforms fly ash concrete in aggressive environments, making it ideal for structures exposed to harsh chemicals and saline conditions.

Sustainability and Environmental Benefits

Silica fume concrete offers superior sustainability through its high pozzolanic activity, which enhances durability and reduces cement demand, leading to lower carbon emissions. Fly ash concrete promotes environmental benefits by recycling industrial by-products, reducing landfill waste, and improving energy efficiency in production. Both materials contribute significantly to sustainable construction by minimizing the ecological footprint of concrete while enhancing mechanical properties.

Cost Efficiency and Availability

Silica fume concrete offers high strength and durability but comes at a higher cost due to limited availability and production complexity. Fly ash concrete is generally more cost-efficient, benefiting from widespread availability as a byproduct of coal combustion in power plants, reducing overall material expenses. Regional differences in supply chains and market demand significantly impact the cost efficiency and accessibility of both supplementary cementitious materials in concrete production.

Mix Design Considerations for Each Material

Silica fume concrete requires a high water-to-cement ratio adjustment due to its fine particles, which enhance density and reduce permeability but increase mix water demand. Fly ash concrete benefits from slower pozzolanic reactions, necessitating extended curing times and careful proportioning to maintain workability and strength development. Both materials demand precise admixture optimization to balance fluidity and durability in the final mix design.

Common Applications in Modern Construction

Silica fume concrete is commonly used in high-performance applications such as bridges, tunnels, and high-rise buildings due to its enhanced durability and high compressive strength. Fly ash concrete is frequently utilized in large-scale construction projects like highways, dams, and mass concrete structures, offering improved workability and reduced heat of hydration. Both materials contribute to sustainable construction by improving concrete longevity and reducing cement consumption.

Selecting the Right Supplementary Cementitious Material

Selecting the right supplementary cementitious material (SCM) depends on desired concrete properties and project requirements. Silica fume concrete offers superior strength and durability due to its fine particles and high pozzolanic activity, making it ideal for high-performance structures. Fly ash concrete improves workability and reduces heat of hydration, providing cost-effective sustainability benefits for large-scale construction.

Silica Fume Concrete vs Fly Ash Concrete Infographic

materialdif.com

materialdif.com