Rebar reinforcement provides high tensile strength and structural stability, making it ideal for heavy-load concrete applications such as bridges and foundations. Fiber reinforcement enhances crack resistance and improves durability by distributing stress throughout the concrete matrix, often used in slabs and overlays. Combining both methods can optimize performance, balancing strength and flexibility for various construction needs.

Table of Comparison

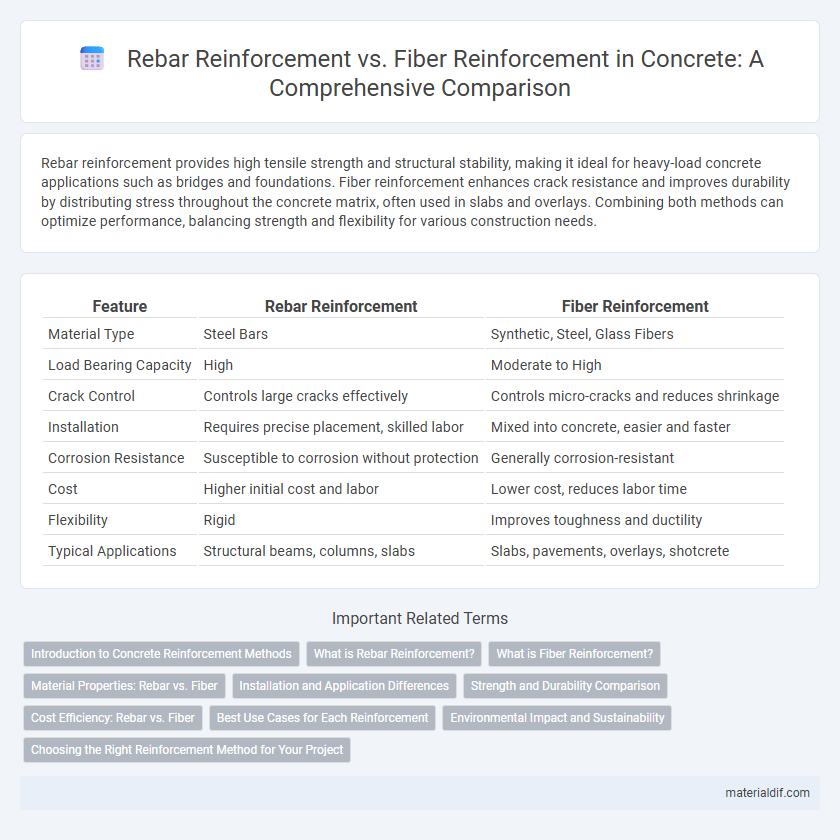

| Feature | Rebar Reinforcement | Fiber Reinforcement |

|---|---|---|

| Material Type | Steel Bars | Synthetic, Steel, Glass Fibers |

| Load Bearing Capacity | High | Moderate to High |

| Crack Control | Controls large cracks effectively | Controls micro-cracks and reduces shrinkage |

| Installation | Requires precise placement, skilled labor | Mixed into concrete, easier and faster |

| Corrosion Resistance | Susceptible to corrosion without protection | Generally corrosion-resistant |

| Cost | Higher initial cost and labor | Lower cost, reduces labor time |

| Flexibility | Rigid | Improves toughness and ductility |

| Typical Applications | Structural beams, columns, slabs | Slabs, pavements, overlays, shotcrete |

Introduction to Concrete Reinforcement Methods

Concrete reinforcement methods primarily include rebar reinforcement and fiber reinforcement, each enhancing the material's tensile strength and durability. Rebar reinforcement uses steel bars to provide substantial structural support and resist cracking under heavy loads, making it ideal for large-scale construction projects. Fiber reinforcement involves integrating synthetic or steel fibers into the concrete mix, improving crack control and impact resistance while allowing for easier handling and faster application.

What is Rebar Reinforcement?

Rebar reinforcement consists of steel bars embedded in concrete to enhance tensile strength and prevent cracking under stress. Widely used in structural applications, rebar provides superior durability and load-bearing capacity compared to fiber reinforcement. The high tensile strength of steel rebar ensures concrete structures can withstand significant mechanical forces and environmental pressures over time.

What is Fiber Reinforcement?

Fiber reinforcement in concrete involves embedding small, discrete fibers made from materials such as steel, glass, synthetic polymers, or natural fibers to enhance the material's structural properties. These fibers improve concrete's tensile strength, control cracking, and increase durability by distributing loads more evenly throughout the matrix. Unlike traditional rebar reinforcement that uses steel bars for support, fiber reinforcement provides multidirectional strength and reduces the risk of localized failure in concrete structures.

Material Properties: Rebar vs. Fiber

Rebar reinforcement offers high tensile strength and ductility, making it ideal for structural concrete applications requiring significant load-bearing capacity and crack control. Fiber reinforcement, typically made from steel, glass, synthetic, or natural fibers, enhances concrete's tensile strength, impact resistance, and shrinkage control by distributing stress more evenly throughout the matrix. While rebar provides localized reinforcement, fibers improve overall material toughness and durability, particularly in thin or complex geometries where traditional rebar placement may be challenging.

Installation and Application Differences

Rebar reinforcement involves placing steel bars within concrete forms, requiring precise positioning and securing to maintain structural integrity during pouring, commonly used in heavy load-bearing applications such as foundations and beams. Fiber reinforcement consists of adding synthetic or steel fibers directly into the concrete mix, streamlining installation by eliminating the need for tying or positioning, and is often preferred for controlling shrinkage cracks and enhancing surface durability in slabs and overlays. The choice between rebar and fiber reinforcement depends on project requirements, with rebar offering superior tensile strength in large structural components, while fibers improve impact resistance and reduce labor and installation time.

Strength and Durability Comparison

Rebar reinforcement provides superior tensile strength and load-bearing capacity, making it ideal for structural applications requiring high durability under heavy loads. Fiber reinforcement enhances crack resistance and toughness, improving concrete's durability against shrinkage and impact while reducing the risk of surface fractures. Combining rebar and fiber reinforcement often optimizes both strength and durability in concrete structures.

Cost Efficiency: Rebar vs. Fiber

Rebar reinforcement generally involves higher material and labor costs due to the need for skilled installation and complex placement procedures, making it less cost-efficient for smaller projects. Fiber reinforcement, typically composed of synthetic or steel fibers, offers a lower initial cost and reduces labor expenses by simplifying the mixing and pouring process. This cost efficiency combined with improved crack control makes fiber reinforcement a preferred choice for cost-sensitive concrete applications.

Best Use Cases for Each Reinforcement

Rebar reinforcement excels in structural applications requiring high tensile strength and load-bearing capacity, such as foundations, beams, and columns in commercial and residential buildings. Fiber reinforcement is ideal for mitigating shrinkage cracks and enhancing impact resistance in slabs, pavements, and precast concrete elements, offering improved durability and reduced maintenance. Selecting rebar or fiber reinforcement depends on the specific engineering requirements, load conditions, and the desired balance between strength and crack control.

Environmental Impact and Sustainability

Rebar reinforcement requires significant energy and raw materials for steel production, leading to a higher carbon footprint compared to fiber reinforcement made from synthetic or natural fibers. Fiber reinforcement improves sustainability by reducing overall material consumption, enhancing durability, and enabling thinner concrete sections that decrease resource demand. Incorporating fiber reinforcement can substantially lower environmental impact through reduced emissions, waste, and extended service life of concrete structures.

Choosing the Right Reinforcement Method for Your Project

Choosing the right reinforcement method for your concrete project depends on factors such as structural demands, durability requirements, and cost-effectiveness. Rebar reinforcement offers superior tensile strength and is ideal for large-scale structural elements, while fiber reinforcement enhances crack resistance and improves impact durability in slabs and overlays. Evaluating load conditions, environmental exposure, and project budget ensures optimal selection between rebar and fiber reinforcement to achieve long-lasting concrete performance.

Rebar Reinforcement vs Fiber Reinforcement Infographic

materialdif.com

materialdif.com