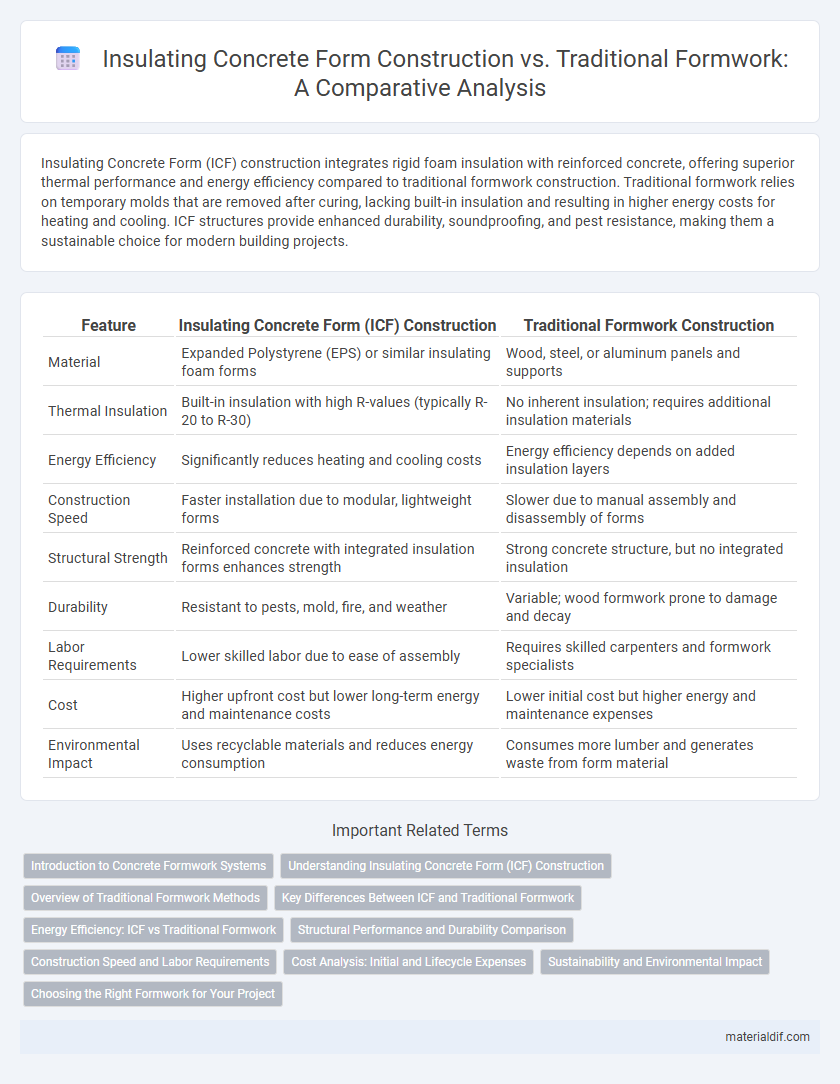

Insulating Concrete Form (ICF) construction integrates rigid foam insulation with reinforced concrete, offering superior thermal performance and energy efficiency compared to traditional formwork construction. Traditional formwork relies on temporary molds that are removed after curing, lacking built-in insulation and resulting in higher energy costs for heating and cooling. ICF structures provide enhanced durability, soundproofing, and pest resistance, making them a sustainable choice for modern building projects.

Table of Comparison

| Feature | Insulating Concrete Form (ICF) Construction | Traditional Formwork Construction |

|---|---|---|

| Material | Expanded Polystyrene (EPS) or similar insulating foam forms | Wood, steel, or aluminum panels and supports |

| Thermal Insulation | Built-in insulation with high R-values (typically R-20 to R-30) | No inherent insulation; requires additional insulation materials |

| Energy Efficiency | Significantly reduces heating and cooling costs | Energy efficiency depends on added insulation layers |

| Construction Speed | Faster installation due to modular, lightweight forms | Slower due to manual assembly and disassembly of forms |

| Structural Strength | Reinforced concrete with integrated insulation forms enhances strength | Strong concrete structure, but no integrated insulation |

| Durability | Resistant to pests, mold, fire, and weather | Variable; wood formwork prone to damage and decay |

| Labor Requirements | Lower skilled labor due to ease of assembly | Requires skilled carpenters and formwork specialists |

| Cost | Higher upfront cost but lower long-term energy and maintenance costs | Lower initial cost but higher energy and maintenance expenses |

| Environmental Impact | Uses recyclable materials and reduces energy consumption | Consumes more lumber and generates waste from form material |

Introduction to Concrete Formwork Systems

Insulating Concrete Form (ICF) construction utilizes interlocking foam panels as permanent molds for concrete, providing enhanced thermal insulation and energy efficiency compared to traditional formwork systems that typically rely on temporary timber or metal molds. ICF systems offer superior strength, durability, and reduced labor costs by combining formwork and insulation in a single step, accelerating construction timelines. Traditional formwork requires removal after concrete curing, whereas ICF remains part of the structure, improving overall building performance and sustainability.

Understanding Insulating Concrete Form (ICF) Construction

Insulating Concrete Form (ICF) construction integrates hollow foam blocks or panels that remain in place as permanent insulation and formwork for concrete walls, offering superior thermal performance and energy efficiency compared to traditional formwork methods. ICF walls provide enhanced structural strength, noise reduction, and moisture resistance due to the combination of reinforced concrete and continuous insulation. This construction technique significantly reduces air infiltration and contributes to sustainable building practices through improved energy conservation and durability.

Overview of Traditional Formwork Methods

Traditional formwork construction employs materials such as timber, steel, and plywood to create molds that shape poured concrete. This method requires extensive labor for assembly, support, and removal, impacting project timelines and costs. Despite its widespread use, traditional formwork often lacks the thermal insulation properties found in newer technologies like Insulating Concrete Form (ICF) systems.

Key Differences Between ICF and Traditional Formwork

Insulating Concrete Form (ICF) construction integrates permanent foam insulation with reinforced concrete, offering superior thermal efficiency and enhanced structural durability compared to Traditional Formwork, which relies on temporary wooden or metal molds for shaping concrete. ICF systems reduce labor time and waste through modular, interlocking panels that remain as part of the building envelope, while Traditional Formwork requires dismantling and often results in higher material consumption. Additionally, ICF provides improved soundproofing and energy performance, making it a preferred choice for sustainable and resilient building projects.

Energy Efficiency: ICF vs Traditional Formwork

Insulating Concrete Form (ICF) construction significantly enhances energy efficiency compared to traditional formwork by providing superior thermal insulation through integrated foam panels, reducing heat loss by up to 70%. The airtight seal created by ICF walls minimizes air infiltration, leading to lower heating and cooling costs and improved indoor comfort. Traditional formwork lacks continuous insulation, resulting in higher energy consumption and less effective temperature regulation in buildings.

Structural Performance and Durability Comparison

Insulating Concrete Form (ICF) construction significantly enhances structural performance with superior load-bearing capacity and improved resistance to seismic and wind forces compared to traditional formwork construction. ICFs provide continuous insulation and moisture resistance, contributing to greater durability by preventing thermal bridging and reducing the risk of mold or corrosion in the concrete core. Traditional formwork may lack this integrated insulation, leading to potential weaknesses in energy efficiency and long-term material integrity.

Construction Speed and Labor Requirements

Insulating Concrete Form (ICF) construction significantly reduces construction speed by combining formwork and insulation in a single system, enabling faster assembly and fewer construction phases compared to traditional formwork. Labor requirements in ICF systems are lower because they eliminate the need for extensive bracing, stripping, and site cleanup, allowing less specialized labor to efficiently erect the forms. Traditional formwork construction demands more skilled labor and time-intensive processes for setup, alignment, and removal, often leading to longer project timelines and higher labor costs.

Cost Analysis: Initial and Lifecycle Expenses

Insulating concrete form (ICF) construction typically incurs higher initial costs compared to traditional formwork due to specialized materials and labor requirements. However, ICF's superior thermal insulation and energy efficiency reduce lifecycle expenses by lowering heating and cooling costs, often resulting in significant savings over 20 to 30 years. Traditional formwork may have lower upfront expenditures but generally lacks the long-term energy savings and durability benefits associated with ICF systems.

Sustainability and Environmental Impact

Insulating Concrete Form (ICF) construction significantly reduces energy consumption by providing superior thermal insulation compared to traditional formwork, lowering heating and cooling demands throughout a building's lifecycle. ICF systems utilize recyclable materials such as expanded polystyrene, which contribute to waste reduction and decreased landfill impact relative to conventional timber-based formwork that often results in deforestation and higher waste generation. Long-term sustainability benefits of ICF include enhanced durability and reduced air leakage, minimizing resource use for repairs and maintenance, thereby lowering the overall carbon footprint of the built environment.

Choosing the Right Formwork for Your Project

Selecting the right formwork for your project hinges on factors such as thermal insulation, construction speed, and durability. Insulating Concrete Form (ICF) construction offers superior energy efficiency and structural strength by combining rigid insulation with concrete, reducing heating and cooling costs. In contrast, traditional formwork provides cost-effective, versatile shaping options but lacks the integrated insulation and long-term energy savings of ICF systems.

Insulating Concrete Form Construction vs Traditional Formwork Construction Infographic

materialdif.com

materialdif.com